My Garage

My Account

Cart

Genuine Chevrolet Monte Carlo Starter

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Starters found

Chevrolet Monte Carlo Starter, (Remanufacture)

Part Number: 10465490$86.89 MSRP: $263.51You Save: $176.62 (68%)Ships in 1-2 Business DaysChevrolet Monte Carlo Starter Asm, (Remanufacture) (Pg260D)

Part Number: 89017845$311.93 MSRP: $688.90You Save: $376.97 (55%)Ships in 1-2 Business DaysChevrolet Monte Carlo Starter Asm, (Remanufacture Pg260D)

Part Number: 89017714$254.20 MSRP: $504.88You Save: $250.68 (50%)Ships in 1-2 Business DaysChevrolet Monte Carlo Start Motor Assembly (Remanufacture)

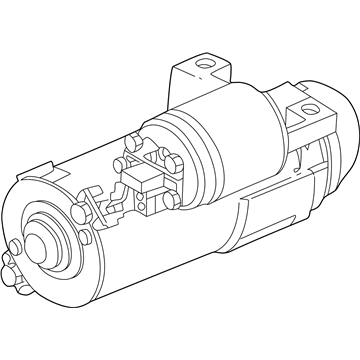

Part Number: 10465459$112.35 MSRP: $339.90You Save: $227.55 (67%)Ships in 1-2 Business DaysChevrolet Monte Carlo Starter Asm, (Remanufacture) (Pg260D)

Part Number: 89017715$306.88 MSRP: $609.93You Save: $303.05 (50%)Ships in 1-2 Business DaysChevrolet Monte Carlo Starter Asm, (Remanufacture) (Pg260G)

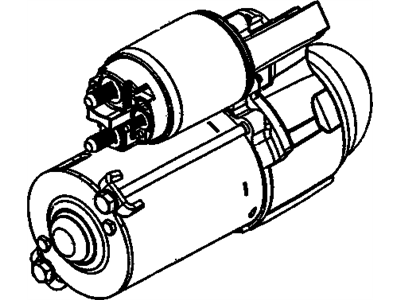

Part Number: 89017716$219.81 MSRP: $412.96You Save: $193.15 (47%)Ships in 1-2 Business DaysChevrolet Monte Carlo STARTER ASM,.

Part Number: 19418857$211.07 MSRP: $383.78You Save: $172.71 (45%)Ships in 1 Business Day

Chevrolet Monte Carlo Starter

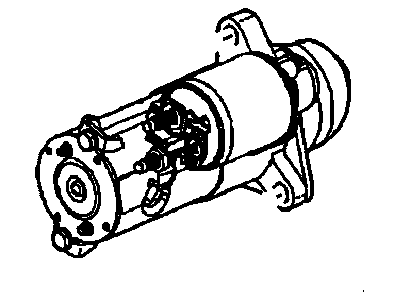

The Chevrolet Monte Carlo's Starter plays a big roll as it is responsible for converting electrical energy from the battery into mechanical energy for cranking the engine. The process is started by an externally mounted solenoid, this is a device that links the battery with the starter motor. In the starter, a rotating armature is involved with field coils or permanent magnet and the necessary electromagnetic force for the turning of the engine is produced. The starter drive meshes with the flywheel of the engine and there is an overrunning clutch which denies engagement of the starter once the engine starts. There are different kinds of starters that have been used on Monte Carlo vehicles in the past, gear reduction starters being one of the models the improve torque output. The starters supplied as original equipment (OE) are adequate for most engines; however, high-performance kits may come equipped with larger ones to cope with higher demand especially where increased compression ratio is in force. They have highlighted more developments that pointed to changes in starter technology that affect the ignition of engine in various Monte Carlo models.

Each OEM Chevrolet Monte Carlo Starter we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Monte Carlo Starter Parts Questions & Experts Answers

- Q: How to remove and install the starter motor on Chevrolet Monte Carlo?A:For V6 models,Disconnect the cable from the negative battery terminal. Raise the front of the vehicle and support it securely on jackstands. Remove the under-engine splash shield. Disconnect the Battery Cable (the larger cable) and the starter control cable (the smaller cable) from the starter solenoid terminals. Remove the driveplate/torque converter access cover. Remove the starter mounting bolts and remove the starter. Installation is the reverse of removal. Be sure to tighten the starter mounting bolts. V8 models: Disconnect the cable from the negative battery terminal. Remove the air filter housing. Disconnect the battery cable (the larger cable) and the starter control cable (the smaller cable) from the starter solenoid terminals. Remove the starter mounting bolts (To detach the starter from a VS engine, remove these two bolts (use a long extension and a universal joint adapter on the socket to access these bolts)) and remove the starter. Installation is the reverse of removal. Be sure to tighten the starter mounting bolts.

- Q: How to diagnose and check a malfunction in the starting circuit and Starter on Chevrolet Monte Carlo?A:It is important to not assume that the malfunctioning starting circuit is caused by the starter. First, consider several key components: Begin with clean and securely connected clamps for the Battery Cables. Replace all damaged battery cables with new ones. Test the battery's condition, and if it does not pass any of these tests, replace it with a new one. Check wiring and connections on the starter solenoid. Are the bolts holding the starter tight enough. Besides, confirm that the shift lever is in PARK or NEUTRAL position only. Try to check out the small wire on your test light or voltmeter for battery voltage at the solenoid while an assistant turns your ignition switch to START if nothing happens when you turn your ignition switch to START but your starter will not engage. If there are no voltages present here, make use of wiring diagrams so as to help you identify which part of your starting system circuit has failed. However, in case voltage is present while still you cannot hear any sound from your starter, then remove and bench test this kind of a component. If you suspect that your starter cranks slowly, measure cranking voltage and current from battery using an induction type ammeter while actuating engine crank mechanism. The battery voltage should never be less than 8.5 volts; besides its current draw measured by an inductive type ammeter must range between 250-400 amps during cranking operation (process). On workbenches take off and examine starters/solenoids assemblies normally if power comes into this device then it means there could be problem with its solenoid/assembly but in extreme cases a jammed engine too can lead to such situation. Is it possible to apply electricity from a battery to S-terminal then observe plunger, lever shift overrunning clutch piston drive. Now depending upon these implications we know whether our starter or solenoid has defects or whether both of them are operational together.