My Garage

My Account

Cart

Genuine Chevrolet Nova Wheel Cylinder

Brake Wheel Cylinder- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Wheel Cylinders found

Chevrolet Nova Wheel Cylinder

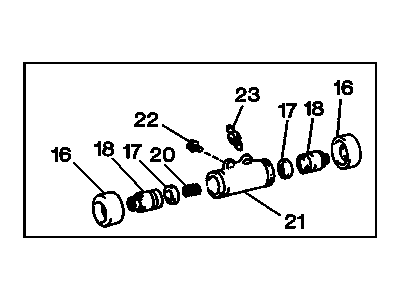

The Wheel Cylinder in Chevrolet Nova cars is part and parcel of the hydraulic drum braking system, whose main and expected function is to push the brake shoes against the brake drum for stopping. It works on the principle of hydrolics where pressure removes pistons within the cylinder which inturn acts on the shoes to make them to be in contact with the drum. The Wheel Cylinder is made up of a central cylinder, two pistons that are sealed with rubber and an expander spring, and New Wheel Cylinder is made of Aluminum so that they do not rust while the Old Wheel Cylinder was made of cast iron. Chevrolet Nova for many years has had different types of Wheel Cylinder specifically one piston Wheel Cylinder and double one piston Wheel Cylinder. Although both types aim at the same function, the design difference may influence the efficiency and ease of maintenance. Periodic checks are required because within Wheel Cylinders, leaks or rusting typically results to loss of braking effectiveness and consequently, the Wheel Cylinder must be either reconstructed or replaced to allow for safe operations on the road.

Each OEM Chevrolet Nova Wheel Cylinder we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Nova Wheel Cylinder Parts Questions & Experts Answers

- Q: How to remove, rebuild and reinstall a wheel cylinder when indicated by fluid leakage or sticky operation on Chevrolet Nova?A:If an overhaul is indicated due to fluid leakage or sticky operation, explore all options before beginning the job. New wheel cylinders are available, making this task quite easy. If rebuilding the wheel cylinder is chosen, ensure a rebuild kit is available beforehand. Always rebuild both wheel cylinders simultaneously. To remove, raise the rear of the vehicle and support it securely on jackstands, blocking the front wheels to prevent rolling. Remove the Brake Shoe assembly and clean all dirt and foreign material from around the wheel cylinder. Unscrew the brake line fitting, completely loosening it before removing the wheel cylinder mounting bolts. For models with retaining clips, use curved needle-nose pliers to remove the clip or insert two awls into the access slots to bend the tabs away. Detach the wheel cylinder from the brake backing plate and place it on a clean workbench, plugging the brake line to prevent fluid loss and contamination. If the brake shoe linings are contaminated with brake fluid, install new brake shoes. For the overhaul, remove the bleeder screw, cups, pistons, boots, and spring assembly from the wheel cylinder body. Clean the wheel cylinder with brake fluid, denatured alcohol, or brake system cleaner, and use compressed air to remove excess fluid and blow out the passages. Check the cylinder bore for corrosion and score marks; use crocus cloth for light corrosion, but replace the cylinder if defects cannot be easily removed or if the bore is scored. Lubricate the new cups with brake fluid and assemble the wheel cylinder components, ensuring the cup lips face inward. For installation, place the wheel cylinder in position and install the bolts or the retaining clip, connect the brake line, and tighten the fitting before installing the brake shoe assembly. Finally, bleed the brakes and check brake operation before driving the vehicle in traffic.