My Garage

My Account

Cart

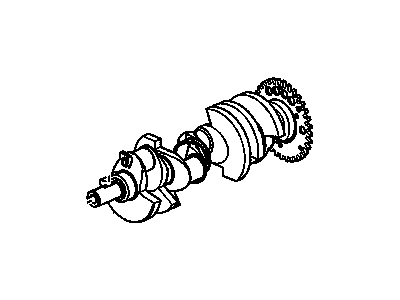

Genuine Chevrolet Trailblazer Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Crankshafts found

Chevrolet Trailblazer Engine Crankshaft

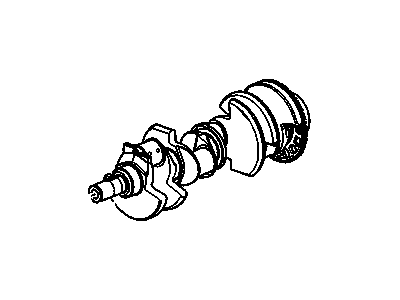

Part Number: 12588614$649.96 MSRP: $960.53You Save: $310.57 (33%)Chevrolet Trailblazer Crankshaft, (Mchg)

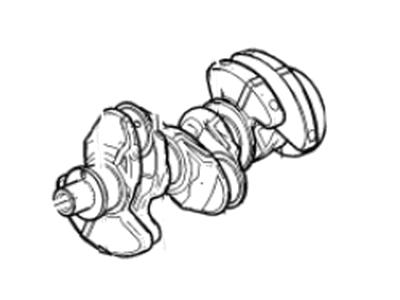

Part Number: 12701729$249.08 MSRP: $412.16You Save: $163.08 (40%)Ships in 1-3 Business DaysChevrolet Trailblazer Crankshaft, (Mchg)

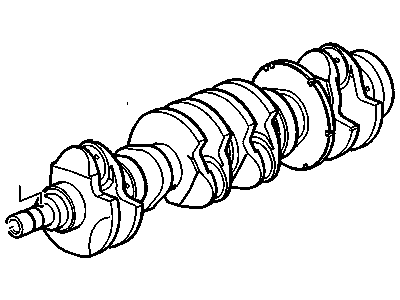

Part Number: 12702504$326.72 MSRP: $540.76You Save: $214.04 (40%)Chevrolet Trailblazer CRANKSHAFT-(MCHG)

Part Number: 25203539$326.72 MSRP: $540.76You Save: $214.04 (40%)Chevrolet Trailblazer Engine Crankshaft

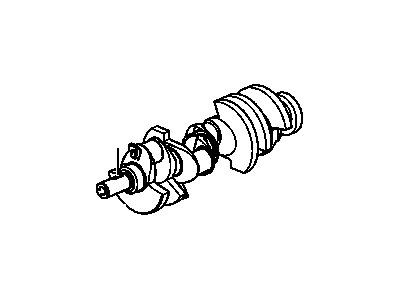

Part Number: 88958866$195.86 MSRP: $309.56You Save: $113.70 (37%)

Chevrolet Trailblazer Crankshaft

Each OEM Chevrolet Trailblazer Crankshaft we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Trailblazer Crankshaft Parts Questions & Experts Answers

- Q: How can the crankshaft be removed and reinstalled on Chevrolet Trailblazer?A:The crankshaft can be removed only if the engine is pulled out of the vehicle presuming that the driveplate, crankshaft pulley, oil pan, timing chain, and Piston/connecting rod assemblies have been removed. Prior to crankshaft removal, check and record crankshaft end play with a dial indicator placed in line with the crankshaft. Move the crankshaft to the rear and bring the indicator to zero and then move the crankshaft to the front and check the new reading which should normally be between 0.003 to 0.010 inch. If a dial indicator cannot be used, clearance may be measured using feeler gauges as can be observed in Fig. Tighten the main bearing cap bolts gradually until they are lightly seized, then remove the main bearing cap stiffener and if necessary mark the caps 1 & 2. It is safer to lift out the crankshaft, if possible with aid, and fit the main bearing caps and the stiffener very loosely but the correct way around. Bearing in mind installation, the block should be oriented such that it's resting on its bottom end; you will also need to pull out any stock bearing inserts and clean the bearing housing machined surfaces. Place new upper main bearing inserts into the main bearing saddles and make certain that oil holes coincide; fit the thrust washer to the number 5 crankshaft journal. Scrub the crankshaft and the insert end of the bearing and put the crankshaft into place. Inspect the oil clearance of the main bearing with the Plastigage installed; it should be installed just slightly less than the width of the journal and tighten the main bearing cap assembly without disturbing the Plastigage. In the designed sequence, further tighten the bolts and then take out the bolts and with the help of scale measure the Plastigage width. If the clearance is wrong it is wise to check for cleanliness and also consider having a change in the bearing inserts. It is always recommended that once Plastigage has been scraped off one should apply a thin coat of grease or assembly lube to the bearing surface as well as the thrust faces and re-fits crankshaft and main bearing cap. Loosening of bolts results into incorrect crank shaft end play so tighten the bolts and check end play and see that it is correct. Try and turn the crankshaft by hand so as to check for tightness, and if okay go ahead and fit the new rear main oil seal.