My Garage

My Account

Cart

Genuine Chevrolet Trailblazer Starter

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Starters found

Chevrolet Trailblazer Starter Asm, (Remanufacture) (Pg260D)

Part Number: 19180529$219.54 MSRP: $435.80You Save: $216.26 (50%)Ships in 1-2 Business DaysChevrolet Trailblazer Starter Asm, (Remanufacture) (Pg260D)

Part Number: 89018123$270.93 MSRP: $538.24You Save: $267.31 (50%)Ships in 1-2 Business DaysChevrolet Trailblazer Starter, (Remanufacture)

Part Number: 89017844$298.72 MSRP: $659.63You Save: $360.91 (55%)Ships in 1-2 Business DaysChevrolet Trailblazer Starter Asm, (Remanufacture) (Pg260H)

Part Number: 19180528$220.54 MSRP: $437.81You Save: $217.27 (50%)Ships in 1-2 Business DaysChevrolet Trailblazer Starter, (Remanufacture)

Part Number: 89017846$323.26 MSRP: $642.55You Save: $319.29 (50%)Chevrolet Trailblazer Starter, (Remanufacture)

Part Number: 89017557$238.48 MSRP: $473.56You Save: $235.08 (50%)Ships in 1-2 Business DaysChevrolet Trailblazer Starter (Remanufacture)

Part Number: 19168039$266.90 MSRP: $530.18You Save: $263.28 (50%)Ships in 1-2 Business DaysChevrolet Trailblazer Starter, (Remanufacture)

Part Number: 10465561$294.83 MSRP: $585.87You Save: $291.04 (50%)Ships in 1-2 Business DaysChevrolet Trailblazer Starter Assembly, .

Part Number: 12697399$134.17 MSRP: $253.16You Save: $118.99 (47%)Ships in 1-3 Business DaysChevrolet Trailblazer STARTER ASM-.

Part Number: 55515481$421.19 MSRP: $765.81You Save: $344.62 (45%)

Chevrolet Trailblazer Starter

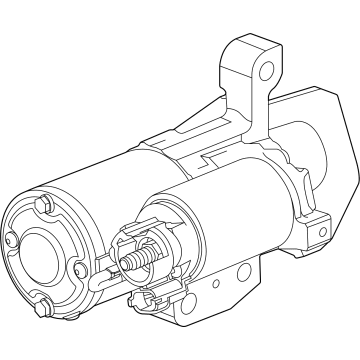

Starter in Chevrolet Trailblazer automobiles is one of the most vital working parts and it generates the mechanical power essential to crank the engine from the electrical power in the battery. This is done by a solenoid which is connected to the battery, this in turn switches on the starter motor and a starter drive gear meshes with the engine's flywheel. The starter motor internal part consists of: rotating armature, field coil or permanent magnet, brushes and a commutator to produce the right torque. Most Chevrolet Trailblazers across the years have had electric starters and there are few basic variants such as gear reduction starter which uses a reduction gear for a better performance. These starters are adequate for standard engines, though might not be effective in high compression engines which need durable and larger starters to prevent problems such as a kick back or failure. Starter technology has developed slowly over the years, and advance development such as gear-reduction systems has seen the improvement of efficiency with compactness of the starters to ensure that the engines start in any condition.

Each OEM Chevrolet Trailblazer Starter we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Trailblazer Starter Parts Questions & Experts Answers

- Q: How to remove and install a starter on Chevrolet Trailblazer?A:For six-cylinder models,Disconnect the cable from the negative battery terminal. Loosen the left front wheel lug nuts, then raise the front of the vehicle and support it securely on jackstands. Remove the left front wheel. Disconnect the electrical connections at the starter (Remove the nuts and disconnect the battery cable and the solenoid terminal from the starter (you'll be working through the fenderwell)). Remove the starter nut (top) and bolt (bottom) then remove the starter through the fenderwell (Remove the starter mounting nut and bolt). Installation is the reverse of removal. Tighten the starter mounting fasteners to the specific torque. Install the wheel and lug nuts. Lower the vehicle and tighten the lug nuts to the specific torque. V8 MODELS: Disconnect the cable from the negative battery terminal. Raise the vehicle and support it securely on jackstands. Detach any brackets from the rear steering gear crossmember, then remove it or, remove the catalytic converter for clearance as necessary. Note: It should not be necessary to remove both components. Remove the engine splash shield. Remove the starter solenoid shield and the transmission bell housing bolt (Remove the transmission bellhousing cover bolt). Remove the starter mounting bolts (Remove the starter mounting bolts). Carefully lower the starter with the terminals facing toward the front of the vehicle. Disconnect the wires from the terminals on the starter solenoid (Remove the nuts and disconnect the battery cable and the solenoid terminal from the starter) and remove the starter from the vehicle. Installation is the reverse of removal.

- Q: How to diagnose and check a malfunction in the starting circuit and Starter on Chevrolet Trailblazer?A:The above scenario is about starter circuits. The starting circuit of a car malfunctions for different reasons; therefore, it would be wrong to always assume that the problem emanates from a defective starter. Before investigating the starting circuit in depth, we should also examine the connections between the Battery Cable clamps and battery terminals making sure they are clean and tight. Replace any damaged ones among the battery cables. However, if it does not pass any tests, then it is supposed to be replaced. Evaluate the connection of wiring and connections to the Starter along with the tightness of its mounting bolts. Check out related fuses in the engine compartment (fuse box) that might have blown off. Assessing the ignition switch circuit as well as ensuring appropriate operation of the starter relay situated in underhood electrical center is equally important here. Moreover, these systems must work properly so that power can be safely delivered from battery to relay for starting purposes; meaning, you also need to verify functional condition of Park/Neutral position switch. When you start your vehicle by turning on ignition key from OFF to START and nothing happens (starter stays dead), look for voltage at this location on solenoid so as to verify whether or not such voltage is supplied by relay through them. Keep an eye on what happens at this terminal during an assistant's activation of ignition switch using a 12-volt test light or voltmeter; bright test light or indicated battery voltage on voltmeter confirms presence of voltage. If there is no one present or absent when checking fuses, ignition switch, starter relay or its wires then there is a problem with either fuses, ignition key switch, relay or its wiring respectively where no voltage should be found according to my paper. There are other possibilities that may occur when voltages are available at these two points but motor does not engage when rotating crankshaft pulley by hand after disconnection from load side system termed as rare case. In testing, use battery test clips to connect test battery to starter terminals and then apply voltage from it on S terminal solenoid while observing pinion drive and any movements of solenoid during such actions. The solenoid is working if the pinion drive extends without turning; in this case, however, the problem lies with the motor because it can't turn around when energized by the solenoid. If you hear clicking sound but there is no movement at all, one or both of the solenoid or Starter may be defective. In this case though, you can tell that the starter assembly is good because it has a rotating plunger that extends pinion drive outwards.