My Garage

My Account

Cart

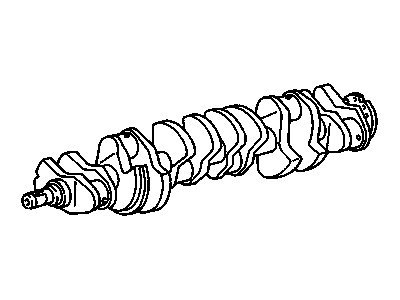

Genuine GMC Jimmy Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Crankshafts found

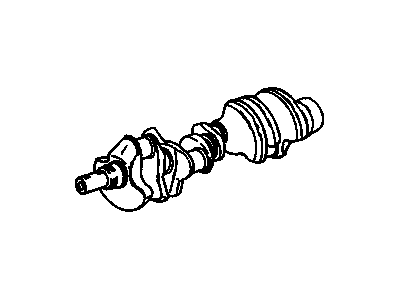

GMC Jimmy Engine Crankshaft

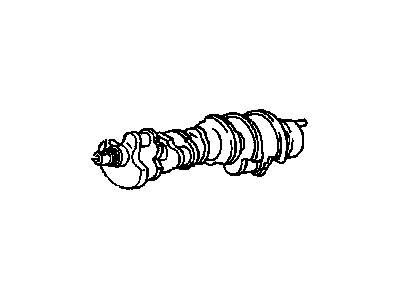

Part Number: 14088526$555.37 MSRP: $670.13You Save: $114.76 (18%)Ships in 1-3 Business DaysGMC Jimmy Engine Crankshaft

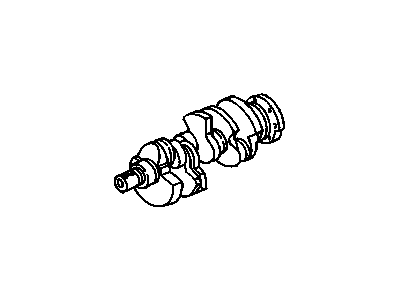

Part Number: 12555637$492.97 MSRP: $815.92You Save: $322.95 (40%)Ships in 1-3 Business Days

GMC Jimmy Crankshaft

Each OEM GMC Jimmy Crankshaft we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

GMC Jimmy Crankshaft Parts Questions & Experts Answers

- Q: How to install a crankshaft during engine reassembly on GMC Jimmy?A:The installation of a crankshaft can be one of the first steps to rebuild an engine, assuming that the crankshaft and engine block have been to a degree of degreasing, inspection and repair. Place the engine upside down and then go ahead and take out the main bearing cap screws and pull out the cap and lay it tactical for easiness of reassembly. In case the old bearing inserts are there, they should be taken out and the main bearing areas should be wiped using a piece of cloth free from any form of lint. New main bearing insert, backs need to be cleaned and one half is fitted into the respective main bearing saddle in the block and tabs and oil holes should align without the use of lubrication. The flanged thrust bearing is to be fitted in suitable cap and saddle according to the type of the engine. Scrub the bearing influences and crankshaft main bearing journals, ensure that the oil channels have dirt. After that, you should clean the crankshaft and, with great accuracy, install counterweights sideways in the main bearings. Examining and measuring Plastigage to control the main bearing oil clearance: Stip trimming Plastigage and installing the same on each crankshaft main bearing journal; it must be parallel to the crankshaft main bearing journal axis. Degrease the bearing faces of the caps and replace them in their original positions with the arrows facing forward then torque the main bearing cap bolts to 90lb.in in three levels without rotating the crankshaft. After loosening the bolts and the caps, check the width of the compressed Plastigage and guarantee that the oil clearance complies with the requirement of the standard. If the clearance is wrong it has to be checked if the size of the bearing inserts is increased by dirt or oil. Remove all the Plastigage material carefully not scratching the bearing faces, lift the crankshaft and also clean the block bearing faces and apply a coat of assembly lube. Install the crankshaft back, also lube the lower bearing halves, and put the caps in as the arrows will indicate forward. For the V6 engines, first center main has to be tightened and then the thrust bearings have to be seated after then rear main cap is to be torqued. On four cylinders engines, torquing must include tightening of all bearing caps to a finger tight stage, setting of thrust bearings then tightening of all bearing caps to the standard torque settings. Turn the crankshaft with your hand and do some check and turn the crankshaft horizontally and do some check and at last perform check of end play of the crankshaft using feeler gauge or dial gauge.