My Garage

My Account

Cart

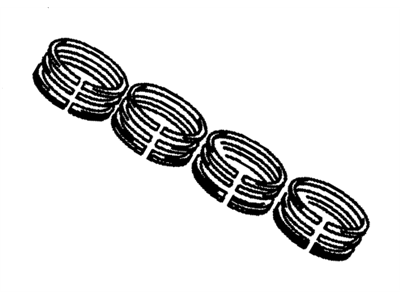

Genuine GMC Jimmy Piston Ring

Piston Ring Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

23 Piston Rings found

GMC Jimmy Ring Kit,Piston(Std)

Part Number: 12528817$62.66 MSRP: $103.72You Save: $41.06 (40%)Ships in 1-3 Business DaysGMC Jimmy Piston Ring Kit

Part Number: 12522848$36.10 MSRP: $87.41You Save: $51.31 (59%)Ships in 1-3 Business DaysGMC Jimmy Ring Kit,Piston(.030 Oversize)

Part Number: 12528819$35.61 MSRP: $71.83You Save: $36.22 (51%)GMC Jimmy Ring Set, Piston, Std, 6.2L

Part Number: 15537018$52.56 MSRP: $82.70You Save: $30.14 (37%)Ships in 1-3 Business DaysGMC Jimmy Ring Unit, Piston (.030 Oversize)

Part Number: 14089026$25.08 MSRP: $50.58You Save: $25.50 (51%)GMC Jimmy Ring Unit, Piston(Std)

Part Number: 12518282$39.23 MSRP: $62.56You Save: $23.33 (38%)Ships in 1-2 Business DaysGMC Jimmy Ring Kit,Piston

Part Number: 88894219$53.27 MSRP: $88.18You Save: $34.91 (40%)Ships in 1-3 Business DaysGMC Jimmy Piston Ring Kit

Part Number: 12524205$44.35 MSRP: $73.40You Save: $29.05 (40%)Ships in 1-3 Business DaysGMC Jimmy Ring Unit, Piston(.030 Os)

Part Number: 12518283$35.39 MSRP: $60.58You Save: $25.19 (42%)Ships in 1-2 Business DaysGMC Jimmy Ring Kit,Piston(.030 Oversize)

Part Number: 12523923$10.41 MSRP: $67.20You Save: $56.79 (85%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 23 Results

GMC Jimmy Piston Ring

The Piston Ring in GMC Jimmy automobiles play the important function of closing the combustion chamber so as to aid the burn of the fuel-air mixture and limit the emission of gases and the consumption of engine oil. These rings normally employ cast iron or steel and are meant to be used in a way that they will produce low friction but at the same time seal efficaciously which is important in the achievement of high efficiency and durability of the engine. Some of the Piston Rings used in GMC Jimmy over the years include the modern thinner Piston Rings with 1mm or 2mm thickness that enables enhanced sealing besides improving the coefficients of friction. These enhancement enables improved compliance to the cylinder bore as well as improved oil retention. The Piston Rings are usually coated with plasma-moly or chrome to enhance heat and wearing resistant which is enhancing the durability of the engine performance on the Gas Machinery Company GMC Jimmy.

Each OEM GMC Jimmy Piston Ring we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

GMC Jimmy Piston Ring Parts Questions & Experts Answers

- Q: How should the piston ring end gaps be checked and corrected before installation on GMC Jimmy?A:When normal Piston rings have been replaced by new ones, the ring end gaps should be checked accordingly supposing that the piston ring side clearance is standard. Stack them with motor and cylinder such that the piston cut and connective piston will also match when measuring the end gap during engine assembly as well as when the new ring sets are positioned. The top ring should be located in the first cylinder and it should be located at the bottom of the cylinder at the piston's lowest limit and it is fitted by being pushed in with the cylinder walls being square to this ring. To check the end gap, place a feeler gauge between the ends of the ring and compare with the needed size as shown in Fig. If the gap is different, check the rings before moving on to the next set of figures etc in the NASM assembly language. If it is less it has to be increased so that the ring ends do not rub against each other when the engine is functioning as it causes severe harm. When the end gap of the ring shape is correct, use a fine file to file the ring ends 'outward only' and to remove traces of the filing with a whetstone. It is not a problem if end gap is more than .040 but double check to be sure that you have the correct rings for your engine. It is necessary to repeat the operation for other rings in the first cylinder and the other cylinders using the rings, pistons, and cylinders matched together. When the measurement of the gaps of the ring end is done, fit the rings on the pistons with the Oil control ring being made up of three parts. Place the spacer expander into the groove then insert the corresponding upper side rail without employing a piston ring installation tool for damaging the rail and do the same for the lower side rail. When the oil ring components are installed, the side rails of the components must be able to rotate freely in the groove. Subsequently, fix the middle ring easily identifiable commonly by use of the piston ring installation tool, and see to it that the mark in the ring is in orients towards the top in the piston. Last, fit the top ring in the same way with the identifying mark in the upward position, and do the same for all the pistons and rings which are very sensitive; the top and the middle rings must not be interchanged.