My Garage

My Account

Cart

Genuine GMC Terrain Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

77 Shock Absorbers found

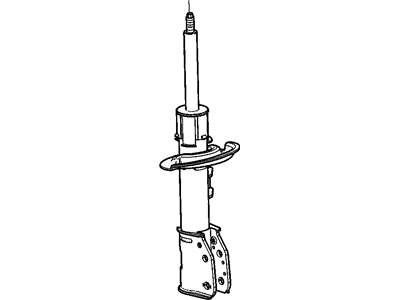

GMC Terrain Front Suspension Strut Assembly

Part Number: 20909156$122.78 MSRP: $239.33You Save: $116.55 (49%)Ships in 1-3 Business DaysGMC Terrain Front Suspension Strut Assembly

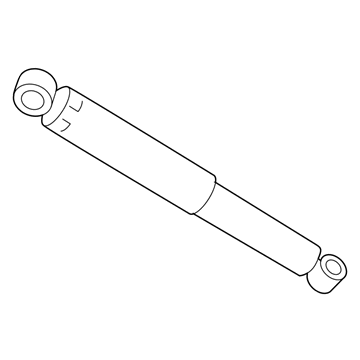

Part Number: 20909157$111.62 MSRP: $217.57You Save: $105.95 (49%)Ships in 1-3 Business DaysGMC Terrain Rear Shock Absorber Assembly

Part Number: 84192068$66.18 MSRP: $127.88You Save: $61.70 (49%)GMC Terrain Front Suspension Strut Assembly

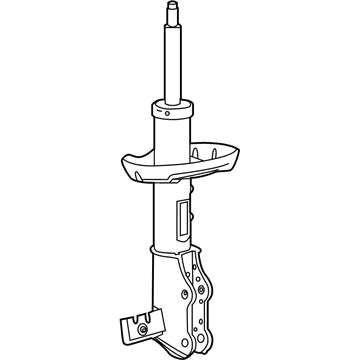

Part Number: 20909154$93.10 MSRP: $257.04You Save: $163.94 (64%)Ships in 1-2 Business DaysGMC Terrain Front Suspension Strut Assembly

Part Number: 20909155$93.10 MSRP: $257.04You Save: $163.94 (64%)Ships in 1-2 Business DaysGMC Terrain Front Suspension Strut Assembly

Part Number: 84339441$106.39 MSRP: $209.23You Save: $102.84 (50%)Ships in 1-2 Business DaysGMC Terrain Front Suspension Strut Assembly

Part Number: 84339439$95.12 MSRP: $187.07You Save: $91.95 (50%)GMC Terrain Front Suspension Strut Assembly

Part Number: 20909158$73.44 MSRP: $202.76You Save: $129.32 (64%)Ships in 1-2 Business DaysGMC Terrain Front Suspension Strut Assembly

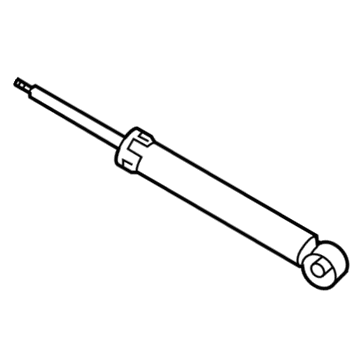

Part Number: 84912403$77.62 MSRP: $152.64You Save: $75.02 (50%)Ships in 1-2 Business DaysGMC Terrain Rear Shock Absorber Assembly

Part Number: 84192069$70.97 MSRP: $129.07You Save: $58.10 (46%)GMC Terrain Front Suspension Strut Assembly

Part Number: 84865811$83.51 MSRP: $151.84You Save: $68.33 (45%)Ships in 1-2 Business DaysGMC Terrain Front Suspension Strut Assembly

Part Number: 20909159$111.79 MSRP: $203.24You Save: $91.45 (45%)Ships in 1-2 Business DaysGMC Terrain Front Suspension Strut Assembly

Part Number: 84912402$77.62 MSRP: $152.64You Save: $75.02 (50%)Ships in 1-3 Business DaysGMC Terrain Rear Shock Absorber Assembly With Upper Mount

Part Number: 84361770$69.34 MSRP: $126.08You Save: $56.74 (45%)Ships in 1-2 Business DaysGMC Terrain Rear Shock Absorber Assembly With Upper Mount

Part Number: 84293473$73.51 MSRP: $138.70You Save: $65.19 (47%)Ships in 1-2 Business DaysGMC Terrain Rear Shock Absorber Assembly With Upper Mount

Part Number: 84361769$93.02 MSRP: $175.50You Save: $82.48 (47%)Ships in 1-2 Business DaysGMC Terrain Front Suspension Strut Assembly

Part Number: 84339443$95.16 MSRP: $173.01You Save: $77.85 (45%)Ships in 1-2 Business DaysGMC Terrain Front Suspension Strut Assembly

Part Number: 84339442$91.26 MSRP: $172.18You Save: $80.92 (47%)Ships in 1-2 Business DaysGMC Terrain Front Suspension Strut Assembly

Part Number: 22872083$112.54 MSRP: $202.78You Save: $90.24 (45%)GMC Terrain Front Suspension Strut Assembly

Part Number: 22872084$113.63 MSRP: $204.75You Save: $91.12 (45%)

| Page 1 of 4 |Next >

1-20 of 77 Results

GMC Terrain Shock Absorber

Shock Absorber of GMC Terrain vehicles is one of the main components of the suspension system and assists struts to stabilize the vehicle. This way the Shock Absorber transforms kinetic energy into heat and thus demultiples shock impulses as well as minimizes the movements of the suspension, thus enhancing vehicle stability and comfort. Terrain vehicles that have been produced year after year have incorporated the use of different types of Shock Absorber which include the twin-tube as well as the mono-tube and they function in different styles, these are in the way that the hydraulic fluid flow is managed and the manner in which performance is increased in accordance with the different forms of driving that is encountered. Systems such as Position Sensitive Damping (PSD) and Acceleration Sensitive Damping (ASD) continue to improve the Shock Absorber specialization of specific driving scenarios and setups, as well as options including the electrorheological and magnetorheological suspension technologies which may be active in providing comfort and control adaptability.

Each OEM GMC Terrain Shock Absorber we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

GMC Terrain Shock Absorber Parts Questions & Experts Answers

- Q: How to disassemble and reassemble a Coil Springs and Shock Absorber assembly on GMC Terrain?A:If the struts or coil springs show signs of wear such as leaking fluid, loss of damping capability, chipped, sagging, or cracked coil springs, it is important to explore all options before starting any work. The strut/shock absorber assemblies cannot be serviced and must be replaced if there is a problem. However, there may be strut assemblies available with springs on an exchange basis, which can save time and effort. Before disassembling the vehicle, it is recommended to check the cost and availability of parts. To disassemble, the strut and spring assembly should be removed and mounted in a vise, taking care to protect the unit. A spring compressor should be installed following the manufacturer's instructions to relieve force from the upper spring seat. The damper shaft nut should be loosened and removed, along with the suspension support. The bearing and rubber portion of the suspension support should be inspected and replaced if necessary. The top mount assembly and upper spring seat should be removed, checking for cracking and replacing if needed. The compressed spring should be carefully lifted and set aside. The dust boot and rubber bumper should be removed, and the lower insulator should be checked for wear and replaced if necessary. To reassemble, if the lower insulator is being replaced, it should be set into position with the dropped portion seated properly. The dust boot should be replaced, and the damper rod should be extended and the rubber bumper installed. The coil spring should be placed onto the lower insulator, with the end resting properly. The upper spring seat and top mount should be installed, aligning them correctly. The damper nut should be tightened to the specified torque, and the spring compressor tool can be removed.