My Garage

My Account

Cart

Genuine GMC Yukon Oil Pan

Oil Drain Pan- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

21 Oil Pans found

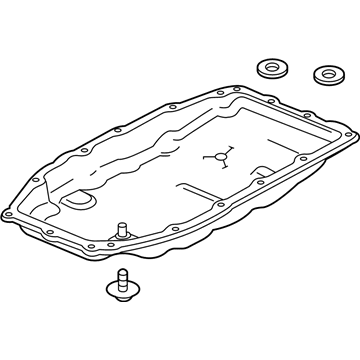

GMC Yukon Lower Engine Oil Pan

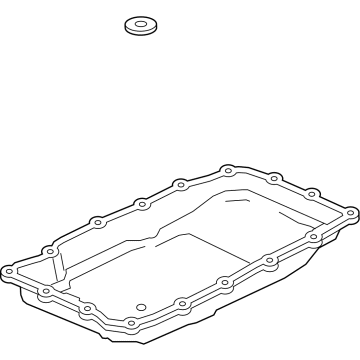

Part Number: 12669909$45.89 MSRP: $79.14You Save: $33.25 (43%)Ships in 1-2 Business DaysGMC Yukon Pan Assembly, Oil

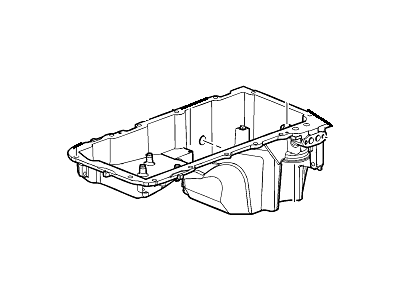

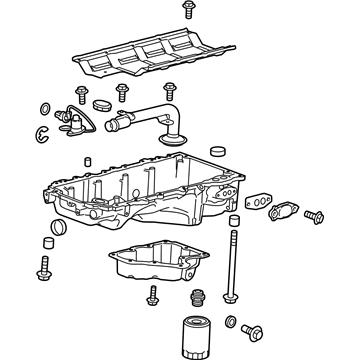

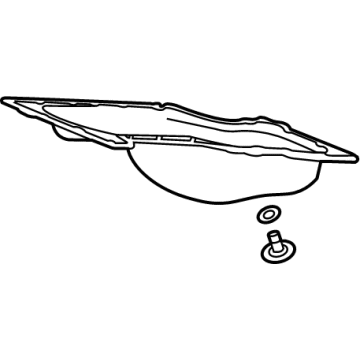

Part Number: 12640746$224.03 MSRP: $383.11You Save: $159.08 (42%)Ships in 1-2 Business DaysGMC Yukon Oil Pan Assembly

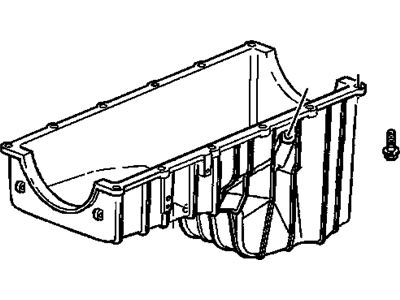

Part Number: 12609074$202.60 MSRP: $349.48You Save: $146.88 (43%)Ships in 1-2 Business DaysGMC Yukon Oil Pan

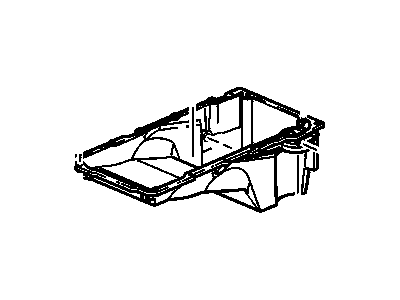

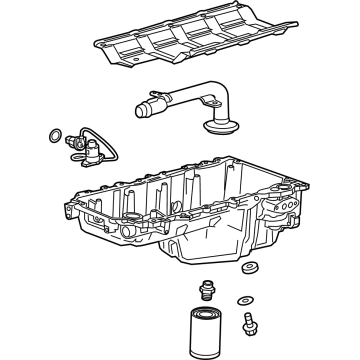

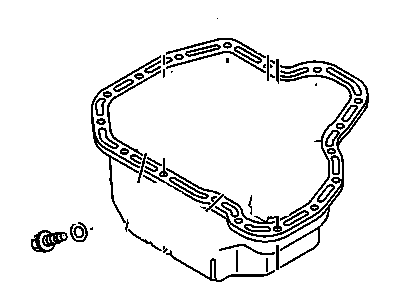

Part Number: 12557558$174.95 MSRP: $301.79You Save: $126.84 (43%)Ships in 1-3 Business DaysGMC Yukon Pan,Oil (W/Filt Bypass)

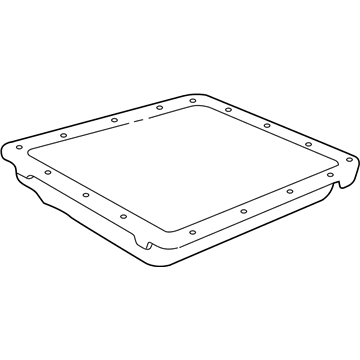

Part Number: 12579273$299.07 MSRP: $511.38You Save: $212.31 (42%)Ships in 1-2 Business DaysGMC Yukon Pan Assembly, A/Trns Fluid

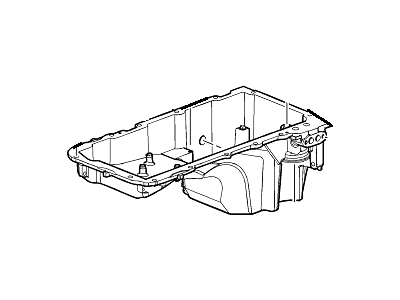

Part Number: 24045035$30.48 MSRP: $48.61You Save: $18.13 (38%)Ships in 1-2 Business DaysGMC Yukon Oil Pan Assembly

Part Number: 12684605$200.30 MSRP: $331.50You Save: $131.20 (40%)Ships in 1-3 Business DaysGMC Yukon Pan Assembly, A/Trns Fluid

Part Number: 24045038$43.19 MSRP: $68.88You Save: $25.69 (38%)Ships in 1-2 Business DaysGMC Yukon Oil Pan Assembly

Part Number: 12619011$138.93 MSRP: $219.58You Save: $80.65 (37%)Ships in 1-3 Business Days

| Page 1 of 2 |Next >

1-20 of 21 Results

GMC Yukon Oil Pan

The Oil Pan of GMC Yukon vehicles is in the same category with any other automobile engine lubrication pan that holds the oil to lubricate and cool the engines moving parts. The majority of Yukon's vehicles employ the wet sump system in which the oil pump suck the oil through a pickup tube situated in the pan to move it within the engine. The oil then recycles to the oil pan, a container expected to contain sufficient of oil for all the operational conditions of the vehicle. For the previous generations of Yukon the engine may have stamped steel oil pans while the newer models may come equipped with a cast aluminum oil reservoirs. In general, the Oil Pan of the GMC Yukon vehicles is central to the well-being of the engine and its optimal functioning.

Each OEM GMC Yukon Oil Pan we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

GMC Yukon Oil Pan Parts Questions & Experts Answers

- Q: How to remove and replace the oil pan on V8 engine on GMC Yukon?A:Disconnect the cable from the negative terminal of the battery. Raise the vehicle and support it securely on jackstands, drain the engine oil, and remove the oil filler. Remove the oil pan skid plate, if equipped. Unbolt the steering rack and allow it to hang out of the way. On 4WD vehicles, remove the front differential carrier. Remove the transmission bell housing covers from the rear of the engine block. Remove the crossmember. Remove the lower transmission-to-engine bolt(s). These bolts vary depending on the model of transmission used but all screw into the oil pan. Disconnect the wiring from the engine oil level sensor. Disconnect the wiring harness retainers from the oil pan. Disconnect the oil cooler lines from the oil pan on models with automatic transmissions. Remove all the oil pan bolts, then lower the pan from the engine. The pan will probably stick to the engine, so strike the pan with a rubber mallet until it breaks the gasket seal. Drill out the rivets securing the oil pan gasket to the oil pan and remove the old gasket. Wash out the oil pan with solvent. Thoroughly clean the mounting surfaces of the oil pan and engine block of old gasket material and sealant. Wipe the gasket surfaces clean with a rag soaked in brake system cleaner. Apply a 3/16-inch wide, one-inch long bead of ATV sealant to the corners of the block where the front cover and the rear cover meet the engine block. The gasket tabs protrude at these points and must have sealant around them. Attach the new gasket to the pan, install the pan, and tighten the bolts finger-tight. Be sure the oil gallery passages in the pan and the gasket are aligned properly. Install all of the oil pan mounting bolts snugly. Install the lower transmission mounting bolts snugly. Tighten the oil pan bolts and the transmission bolts to the correct torque specifications. The remainder of installation is the reverse of removal. Add the proper type and quantity of oil, start the engine, and check for leaks before placing the vehicle back in service.

Related GMC Yukon Parts

Browse by Year

2024 Oil Pan 2023 Oil Pan 2022 Oil Pan 2021 Oil Pan 2020 Oil Pan 2019 Oil Pan 2018 Oil Pan 2017 Oil Pan 2016 Oil Pan 2015 Oil Pan 2014 Oil Pan 2013 Oil Pan 2012 Oil Pan 2011 Oil Pan 2010 Oil Pan 2009 Oil Pan 2008 Oil Pan 2007 Oil Pan 2006 Oil Pan 2005 Oil Pan 2004 Oil Pan 2003 Oil Pan 2002 Oil Pan 2001 Oil Pan 2000 Oil Pan 1999 Oil Pan 1998 Oil Pan 1997 Oil Pan 1996 Oil Pan 1995 Oil Pan 1994 Oil Pan 1993 Oil Pan 1992 Oil Pan