My Garage

My Account

Cart

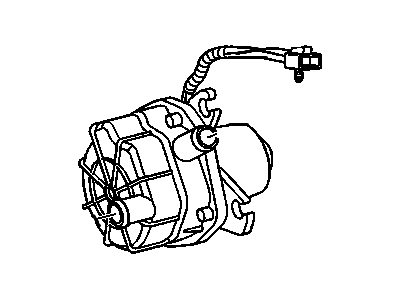

Genuine Oldsmobile Cutlass Secondary Air Injection Pump

Secondary Smog Air Injection Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Secondary Air Injection Pumps found

Oldsmobile Cutlass Pump Assembly, Air Injector

Part Number: 7842076$116.79 MSRP: $224.60You Save: $107.81 (48%)Oldsmobile Cutlass Pump Asm,Secondary Air Injection

Part Number: 7835397$171.33 MSRP: $329.48You Save: $158.15 (48%)

Oldsmobile Cutlass Secondary Air Injection Pump

The Secondary Air Injection Pump in Oldsmobile Cutlass vehicles is a part of the Air Injection Reactor (AIR) system which is used to introduce fresh air into the exhaust cavity with a view of boosting the oxidation of fuel that has not been burnt hence reducing HC&CO emissions. This system usually consist of an electric or belt-driven air pump an air control valve and several check valve all of which control the air supply depending on the engine temperature or any other conditions. Describing air pump operation, in Oldsmobile Cutlass models the air pump draws fresh air through an intake and directs pressurized air to the exhaust ports during warm up to prevent emissions resulting from the rich air/fuel mixture. A fairly heated engine, the air supply passes through an air filter before entering the catalytic converter. Many elements of the design have been integrated to keep backfire and retain exhaust gases from affecting the pump, including diverter valves and one way check valves. It can be seen that details like that of the Secondary Air Injection Pump may differ from one Cutlass model to another but the general function will stay the same in promoting emissions regulation.

Each OEM Oldsmobile Cutlass Secondary Air Injection Pump we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Oldsmobile Cutlass Secondary Air Injection Pump Parts Questions & Experts Answers

- Q: How to diagnose, remove and install Diverter Valve,Secondary Air Injection Check Valve and Secondary Air Injection Pump on Oldsmobile Cutlass?A:The air injection reactor system acts to minimize the amount of hydrocarbons in the exhaust through the introduction of fresh air into the exhaust manifold ports of each engine cylinder helping in the burning of the uncompeted hydrocarbons. It runs through all engine speeds and the passage of air is blocked only sometimes during deceleration and at high speeds when fresh air in abundance may cause back fires. In GM engine, the parts of this system include the air injection pump, an air diverter valve, manifold, and injection tubes, and the check valves that are provided at the end of hose connected to the pump. Installed automotive systems are dependable, but failure of any of them leads to engine surge, back firing, overheating sparks, although the air-pump is the most sensitive part. The drive belt should also be checked for crack or fray and also make sure that it has the right tension. The hose should be examined for flow when the engine is on, and the diverter valve should discharge air when tested. Exhaust gases should not re-enter the air pump and for this; check valves should be installed and the functionality checked. Hose connection leaks can be done with the help of a soapy water solution to identify the leaks. For removal and installation of this air pump, the disconnect hoses, and compress the drive belt and finally remove the securing bolts. The diverter valve comes with hoses as well as securing bolts to be disconnected during removal and also has some particularities to be used with regard to the replacement valves. High temperatures may mean that the air manifold and injection tubes will need penetrating oil to remove and installation needs anti-seize compound on threads. These valves cannot be removed without disconnecting the air supply hose, then using wrenches for slow and cautious removal; the process of installation is similar to the process of removal.

Related Oldsmobile Cutlass Parts

Browse by Year

1999 Secondary Air Injection Pump 1996 Secondary Air Injection Pump 1993 Secondary Air Injection Pump 1992 Secondary Air Injection Pump 1991 Secondary Air Injection Pump 1990 Secondary Air Injection Pump 1989 Secondary Air Injection Pump 1988 Secondary Air Injection Pump 1987 Secondary Air Injection Pump 1986 Secondary Air Injection Pump 1985 Secondary Air Injection Pump 1984 Secondary Air Injection Pump 1983 Secondary Air Injection Pump 1982 Secondary Air Injection Pump