My Garage

My Account

Cart

Genuine Oldsmobile Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

51 Cylinder Heads found

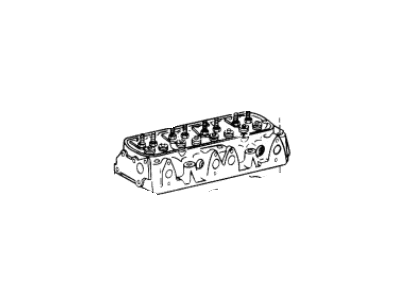

Oldsmobile Cylinder Head Assembly (W/Studs)

Part Number: 12533558$310.73 MSRP: $491.12You Save: $180.39 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Asm,Cyl (W/Studs)

- Replaces: 12533134

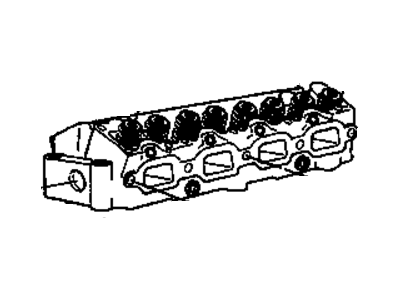

Oldsmobile Engine Cylinder Head (W/Valve)

Part Number: 12360424$1008.05 MSRP: $1303.23You Save: $295.18 (23%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head,Cyl(W/Valve); Cylinder Head

Oldsmobile Engine Cylinder Head

Part Number: 12555630$447.07 MSRP: $713.03You Save: $265.96 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head,Cyl; Cylinder Head

Oldsmobile Cylinder Head Assembly

Part Number: 12558112$596.22 MSRP: $803.53You Save: $207.31 (26%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Head Assembly, Cyl ; Head, Engine Cylinder; Cylinder Head

Oldsmobile Cylinder Head Assembly (Remanufacture)

Part Number: 89037556$153.29 MSRP: $854.17You Save: $700.88 (83%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Head Asm,Cyl(Lh) (Remanufacture) ; Head, Engine Cylinder; Cylinder Head

- Product Specifications

- Other Name: Cylinder Head

- Product Specifications

- Other Name: Head Assembly, Cyl (Machining); Cylinder Head

- Product Specifications

- Other Name: Head Assembly, Cyl ; Head, Engine Cylinder; Cylinder Head

- Product Specifications

- Other Name: Head Assembly, Cyl; Cylinder Head

- Product Specifications

- Other Name: Head Assembly, Cyl ; Head, Engine Cylinder; Cylinder Head

- Product Specifications

- Other Name: Head Assembly, Cyl ; Head, Engine Cylinder; Cylinder Head

- Replaces: 24503436

- Product Specifications

- Other Name: Head, Engine Cylinder; Cylinder Head

- Product Specifications

- Other Name: F, Head, Rem

- Product Specifications

- Other Name: Head Assembly, Cyl (Machining) ; Head, Engine Cylinder; Cylinder Head

- Product Specifications

- Other Name: Head, Engine Cylinder; Cylinder Head

- Product Specifications

- Other Name: Head, Engine Cylinder; Cylinder Head

- Product Specifications

- Other Name: Head,Cyl; Cylinder Head

- Product Specifications

- Other Name: Head,Cyl; Cylinder Head

- Replaces: 10218168

- Product Specifications

- Other Name: Head Assembly, Cyl ; Head, Engine Cylinder; Cylinder Head

- Replaces: 10048649

- Product Specifications

- Other Name: Head Assembly, Cylinder (Service) ; Head, Engine Cylinder; Cylinder Head

| Page 1 of 3 |Next >

1-20 of 51 Results

Oldsmobile Cylinder Head

Looking to acquire brand new parts? Consider exploring our extensive inventory of genuine Oldsmobile Cylinder Heads. Our offering of OEM Oldsmobile Cylinder Heads not only comes with competitive prices but also includes a manufacturer's warranty. For added convenience, we provide a hassle-free return policy and rapid delivery service. Shop with confidence on our platform.

Oldsmobile Cylinder Head Parts Questions & Experts Answers

- Q: What are the steps involved in overhauling cylinder heads in V8 engine on Oldsmobile Cutlass?A:New and rebuilts cylinder heads for GM engines are usually offered at dealers and auto parts stores for replacement practical and feasible for home mechanics to get the replacement heads and install since specialized tools are required for dismantling the heads for inspection and replacement parts may not be available. That said, if one goes for buying complete cylinder heads or overhauling the complete engines at one go, then the cylinder heads can be sent to a professional automotive machine shop or a GM dealership for the process of overhaul. In case the decision to over haul the cylinder heads is made, one needs to know what is involved in the process; the tools required, and cylinder head replacement parts. To start, utilize a valve spring compressor to compress each valve spring and get rid of the valve locking keys and do it one valve in a time. Following the removal of the keys, one pulls the spring and then removes the spring cap, spring shield (if used), spring, and the spring damper and placing these together in a number box or rack utilized when removing the cylinder head in order to organize all valve mechanism parts separately for reassembly. Subsequently, it is also necessary to unscrew the oil seals with reference to the stem of each valve but with the installation of new ones every time therefore if there are any spring shims situated at the bottom of the valve spring should also be removed. Last of all, the valves are all unscrewed one at a time and put one by one in the numbered box or put them on the numbered rack to end the valve mechanism removal while make sure that the valve component will not be placed with the valve component of other valves.

- Q: What are the options for replacing or overhauling cylinder heads on Oldsmobile Omega?A:New and rebuit cylinder heads may be purchased from the dealers and auto parts stores in case of GM engines. Due to the fact that specialized tools are unavailable for dismantling and inspecting the heads and it may be difficult to source for replacement parts or due to the fact that it is usually cheaper for the home mechanic to purchase replacement heads and install them. The other possibility is that one can transport the complete cylinder heads to a professional auto-shops or General Motors dealership for general overhaul. A decision could also be made depending on other information if the complete engine is being overhauled at the same time. If the nuts, balls and rocker arms have not been removed, first, remove the rocker arm nuts, balls and rocker arms. Press down each valve spring with the valve spring compressor and unbolt the valve locking keys and do it to each of the valves. Slide out the keys and then retract the spring and lead to the removal of the spring cap, spring shield if used, spring and the spring damper. Align the cylinder head with a straight edge, and gauge for conformity in terms of warpage using a feeler gauge; remove all the valves and associated machinery and store these parts in cylinder head removal designated tray/box/stand so that they can be realigned as they were. Take out the oil seals installed at the stem of each valve and replace with new ones during reassembly, and where the bottom of the valve spring has additional spring shims, such should also be removed. Last, depressurise, disconnect the air-line, unlock and open the valve and finally slide each of the valves and their respective components in the numbered box or rack to finish the process of removing the valve mechanism and to also make sure that the parts of the valves are secured such that they do not get mixed up.

Related Oldsmobile Parts

Browse by Model

88 Cylinder Head 98 Cylinder Head Achieva Cylinder Head Alero Cylinder Head Aurora Cylinder Head Bravada Cylinder Head Calais Cylinder Head Custom Cruiser Cylinder Head Cutlass Cylinder Head Delta 88 Cylinder Head Firenza Cylinder Head Intrigue Cylinder Head Omega Cylinder Head Silhouette Cylinder Head Toronado Cylinder Head