My Garage

My Account

Cart

Genuine Pontiac G6 Drive Belt

Serpentine Belt- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

7 Drive Belts found

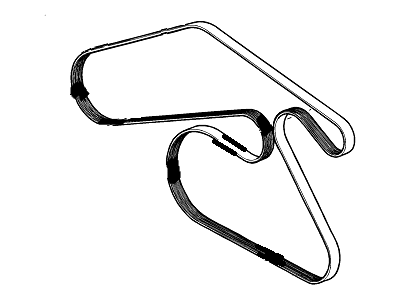

Pontiac G6 Belt, Water Pump & A/C Compressor & Generator & P/S Pump

Part Number: 12577771$38.22 MSRP: $72.12You Save: $33.90 (47%)Ships in 1-3 Business DaysPontiac G6 Belt, Water Pump & A/C Compressor & Generator

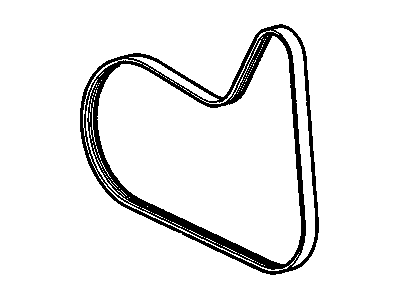

Part Number: 12591059$39.20 MSRP: $70.30You Save: $31.10 (45%)Ships in 1-3 Business DaysPontiac G6 Belt, Water Pump & A/C Compressor & Generator & P/S Pump

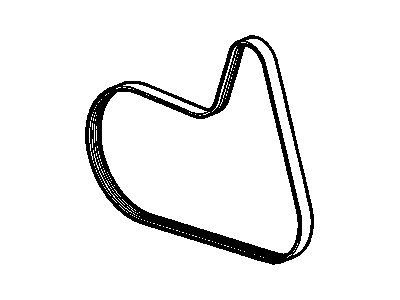

Part Number: 12594450$38.69 MSRP: $70.37You Save: $31.68 (46%)Ships in 1-3 Business DaysPontiac G6 Belt,Generator & A/C Compressor

Part Number: 12639468$20.77 MSRP: $37.28You Save: $16.51 (45%)

Pontiac G6 Drive Belt

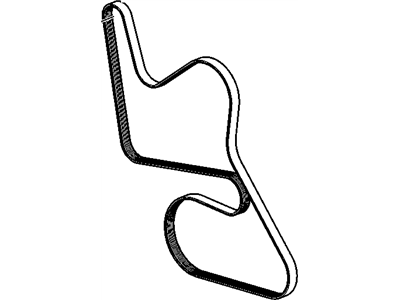

The Drive Belt on Pontiac G6 automobiles play an important role in linking the engine to a number of parts like the more-gen alter native, and the air conditioning compressor. More often than not, a serpentine belt is used, this loops around these parts and connects them to the crankshaft pulley. I understand where this design makes it possible to supply power to several parts through the intermediacy of the engine. Serpentine belts have been predominantly used in the Pontiac G6 models due to its high performance and durability and normally can last up to 100000 miles of normal usage. They however do not last as long as they should due to some factors such as fraying or cracking. Should a Drive Belt get damaged then this poses a great problem not only to the engine but also the various parts hence it is recommended to be replaced often to ensure optimum operations of the vehicle.

Each OEM Pontiac G6 Drive Belt we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac G6 Drive Belt Parts Questions & Experts Answers

- Q: What is the importance of the serpentine drive belt and How to its inspection and replacement on Pontiac G6?A:There is only one serpentine drivebelt placed in front of the engine and it is very important for the working of the engine and its elements, because of its function and because it is made of a material that wears out, that is why it needs to be checked regularly. This belt operates the alternator and the air conditioning compressor while it may not be required to be replaced for up to a hundred thousand miles, inspections must be done according to manufacturers' recommendations. The drivebelt has to be examined for cracks and the separation of the belt plies with the engine switched off and the engine turned to move the belt off the pulleys for better examination. Rotate the belt to reveal its other side so as to assess the state of fraying and glazing; in addition, the pulleys ought to be examined for signs of nicks, cracks, distortion as well as corrosion. Tiny cracks through the edges of the belt ribs are usual among ribbed belts and repairs are not required in this case provided that the cracks are not too large or deep. For four cylinder models, remove the right front wheel lug nuts, lift the car, place it on jackstands, remove the right front wheel and the lower splash shield. To V6 engines, few processors include the removal of the air filter housing, and the engine mount strut. There is a tensioner hole where you can use a 3/8-inch drive ratchet or breakout bar to free the drivebelt tension and must take note of the belt path before disconnecting it from the pulleys. Insert the new drivebelt through the crankshaft, alternator, power steering pump and air conditioning compressor pulleys, where needed, and then release the tensioner to make certain that the belt is correctly situated in all the pulley grooves. For tensioner replacement, the drivebelt is to be removed, the idler pulley loosened on 3.6L V6 models, and the bolt(s) holding the tensioner on the engine. Removal is reversed in order with tensioner bolt(s) and the idler pulley tightened to the correct torque.