My Garage

My Account

Cart

Genuine Pontiac Grand Prix Headlight

Headlamp- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

33 Headlights found

Pontiac Grand Prix Headlamp Capsule Assembly

Part Number: 19149590$127.82 MSRP: $191.96You Save: $64.14 (34%)Ships in 1-2 Business DaysPontiac Grand Prix Headlamp Assembly

Part Number: 25851403$167.55 MSRP: $251.63You Save: $84.08 (34%)Pontiac Grand Prix Headlight Assembly

Part Number: 16513260$138.47 MSRP: $265.26You Save: $126.79 (48%)Pontiac Grand Prix Headlamp Capsule Assembly

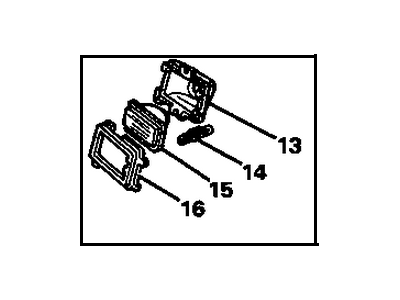

Part Number: 19149589$135.31 MSRP: $135.83You Save: $0.52 (1%)Ships in 1-2 Business DaysPontiac Grand Prix Headlamp Capsule Assembly, (Thin Wall)/Lh

Part Number: 5973932$130.15 MSRP: $187.04You Save: $56.89 (31%)Pontiac Grand Prix Headlamp Assembly

Part Number: 25851404$203.78 MSRP: $306.04You Save: $102.26 (34%)Pontiac Grand Prix Headlight Capsule

Part Number: 5973931$179.66 MSRP: $269.82You Save: $90.16 (34%)

| Page 1 of 2 |Next >

1-20 of 33 Results

Pontiac Grand Prix Headlight

The Headlight of the Pontiac Grand Prix has the basic purpose of providing light on the road ahead and improve visibility especially at night and at the same time make the car visible to other vehicles on the road. Several kinds of the headlights have been fitted in Pontiac Grand Prix models for many years, and these include the halogen, LED as well as the xenon or HID headlights. The halogen headlights are the most popular owing to their low price while the LED headlights though costly are more efficient and have a longer life span. Xenon headlights which are bright white or bluish in color do not have a metal filament as is the case with halogen headlights. As for the headlights of the Pontiac Grand Prix, one can track the evolution of the headlights as a result of the progressive development of the technologies that are intended for increasing the effectiveness and safety of automobiles.

Each OEM Pontiac Grand Prix Headlight we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Grand Prix Headlight Parts Questions & Experts Answers

- Q: How should headlights be aimed correctly to avoid blinding oncoming drivers and ensure safety on Pontiac Grand Prix?A:The headlights should therefore be properly aligned so as not to dazzle other drivers, which can cause very severe road accidents or reduce visibility on the road. The aim should be checked at least once per year and when changing headlight or doing front-end body work. Lending makes a temporary rebound until a specialist fits the corrections. For models from 1996 and earlier, there are two spring-loaded adjusting screws: one attached at top for the up and down movement and another one attached at side for left and right movement. Subsequent models have a bubble level for the scope to make it easier to aim. To adjust them, first, park the car in front of a blank wall at a distance of 25 feet and make sure that the car's floor is horizontal. The vehicle centerline and the centerlines of the two headlights should be indicated using masking tape and a horizontal tape across the middle of the car's width should also be made for balancing purpose. It should be stationary and ideally not pulling a trailer, or towing any object, and the fuel tank should be between half-full and half-empty. For low beam adjustment at the center on the target wall, the high-intensity area is two inches below the horizontal line and two inches to the side of the headlight vertical line, from the path of the oncoming vehicles, while turning the screws. In the case where high beams are on, the high-intensity zone should lie just a little below the horizontal line. When the compromise is made, let it be in favor of the drivers, keeping low beam functioning. The headlights should also be aligned as soon and as often as possible, the best people to do this are technicians from the service department or station.

Related Pontiac Grand Prix Parts

Browse by Year

2008 Headlight 2007 Headlight 2006 Headlight 2005 Headlight 2004 Headlight 2003 Headlight 2002 Headlight 2001 Headlight 2000 Headlight 1999 Headlight 1998 Headlight 1997 Headlight 1996 Headlight 1995 Headlight 1994 Headlight 1993 Headlight 1992 Headlight 1991 Headlight 1990 Headlight 1989 Headlight 1988 Headlight 1987 Headlight 1986 Headlight 1985 Headlight 1984 Headlight 1983 Headlight 1982 Headlight