My Garage

My Account

Cart

Genuine Pontiac Grand Prix Mass Air Flow Sensor

MAF Sensor Meter- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Mass Air Flow Sensors found

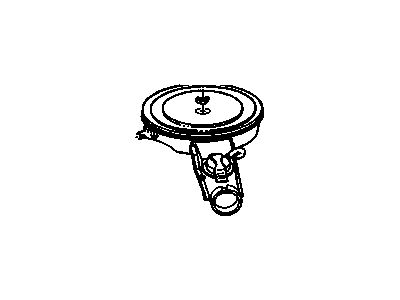

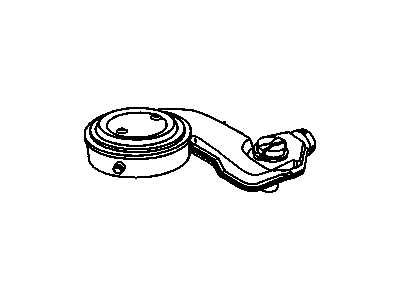

Pontiac Grand Prix Sensor Asm,Mass Airflow

Part Number: 19179715$234.44 MSRP: $478.26You Save: $243.82 (51%)Ships in 1-2 Business DaysPontiac Grand Prix Sensor Asm,Mass Airflow

Part Number: 19179716$242.66 MSRP: $457.83You Save: $215.17 (47%)Ships in 1-2 Business DaysPontiac Grand Prix Mass Airflow Sensor Assembly (Remanufacture)

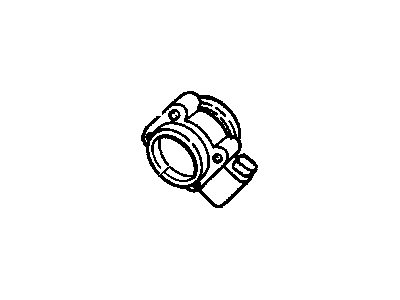

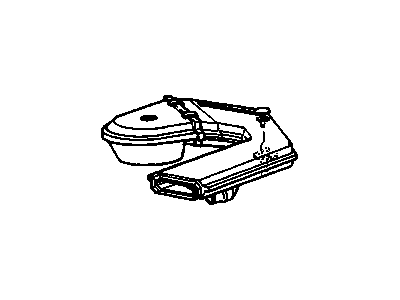

Part Number: 19112538$133.67 MSRP: $238.46You Save: $104.79 (44%)Ships in 1-3 Business DaysPontiac Grand Prix SENSOR ASM,MASS AIRFLOW (W/O TUBE)

Part Number: 19420212$296.21 MSRP: $533.72You Save: $237.51 (45%)Pontiac Grand Prix Mass Airflow Sensor Assembly (Remanufacture)

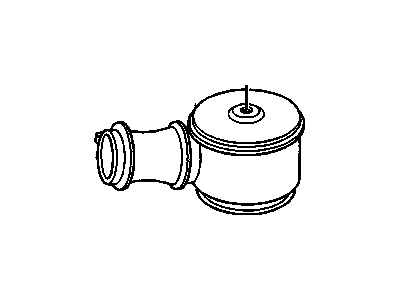

Part Number: 19112543$71.84 MSRP: $126.48You Save: $54.64 (44%)

Pontiac Grand Prix Mass Air Flow Sensor

The Mass Air Flow Sensor in Pontiac Grand Prix is responsible for the measurement of air flow into the engine which is vital for efficient engine performance. This is sent to the PCM which in turn puts the fuel injection in an appropriate level to ensure right air fuel mixture for combustion process. Many models of the Pontiac Grand Prix have incorporated Vane Meter also known as VAF and the Hot Wire type of MAF sensors. The VAF sensor though very effective has drawbacks like limitations of airflow area and losses through mechanical wear while the Hot Wire sensor though very accurate and capable of dynamic adjustments has drawbacks of accuracy reduction through contamination. The Mass Air Flow Sensor should be well maintained to avoid malfunctions such as stalling or even wrong proportions of air and fuel hence enabling the operation of Pontiac Grand Prix to be optimal.

Each OEM Pontiac Grand Prix Mass Air Flow Sensor we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Grand Prix Mass Air Flow Sensor Parts Questions & Experts Answers

- Q: How to Test Mass Air Flow Sensor,Neutral Safety Switch,Oxygen Sensor and Power Steering Pressure Switch on Pontiac Grand Prix?A:When testing, only use a high-impedance (10 mega ohms) digital multi-meter to avoid shorting / shocking the PCM out. On models that are fitted with a Theftlock audio system, verify that the lock out feature is switched off before removing the battery terminal. The self-diagnosis system can only be activated by the TECH 1 SCAN tool-if that is not available, obtain the vehicle codes from a dealer or an authorized repair center. Thermistors that are resistors with varying resistance according to the temperature ought to be high when the temperature is low, and low as the temperature increases. To verify, turn on the multi-meter by selecting the ohms range, remove the harness connector and then place the test probe of the multi-meter on both terminals of the sensor. After checking resistance, check for reference voltage from computer it should be 5.0 volts with ignition switch on. Electrical rotary devices such as the throttle position signal should be tested by back probing the harness connector and noting voltage changes when the signal arm is varied. Intake manifold pressure/vacuum sensor monitors the pressure variation at the intake manifold and should display voltage from below 2.0V when the engine is idle to above 4.0V WOT. Magnetic reluctance sensors including crankshaft and vehicles speed sensors include observing fluctuation of voltage by using AC volt meter when the engine is cranking or by rotating the sensor. Hall effect sensors output ON/OFF signals to the powertrain control module, and should display voltages when the engine is turned over. Dual Hall effect sensors work in the same manner, but they give two different ON/OFF signals. Oxygen sensors measure exhaust gas oxygen content with a voltage signal range of 0.1-0.9 Volts: test for millivolt signals as the engine warms. MAF sensor, records the air getting into the engine and its readout is in grams per second by use of a SCAN tool. Engine vibration is sensed by Knock Sensors and they generate ac output voltage which should vary when tapped. The NVLD switch lights up when the transaxle is in Park/Neutral taping various systems. The PCM acts on the acoustic knock sensors to alter engine load and the air conditioning compressor clutch for the same as well as the power steering pressure sensor to observe fluid pressure that may cause idle problems. The fuel tank pressure sensor is used during emissions checking of the pressure while the Torque Converter Clutch system in automatic transaxles operates to lock the torque converter at cruising speed while allowing minor adjustments to fuel saving; it requires tools that are special to check and repair.

Related Pontiac Grand Prix Parts

Browse by Year

2008 Mass Air Flow Sensor 2007 Mass Air Flow Sensor 2006 Mass Air Flow Sensor 2005 Mass Air Flow Sensor 2004 Mass Air Flow Sensor 2003 Mass Air Flow Sensor 2002 Mass Air Flow Sensor 2001 Mass Air Flow Sensor 2000 Mass Air Flow Sensor 1999 Mass Air Flow Sensor 1998 Mass Air Flow Sensor 1997 Mass Air Flow Sensor 1996 Mass Air Flow Sensor 1995 Mass Air Flow Sensor 1994 Mass Air Flow Sensor 1988 Mass Air Flow Sensor 1987 Mass Air Flow Sensor 1986 Mass Air Flow Sensor 1985 Mass Air Flow Sensor 1984 Mass Air Flow Sensor 1983 Mass Air Flow Sensor 1982 Mass Air Flow Sensor