My Garage

My Account

Cart

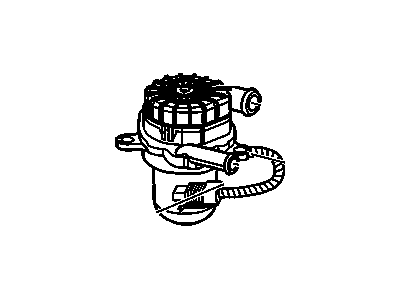

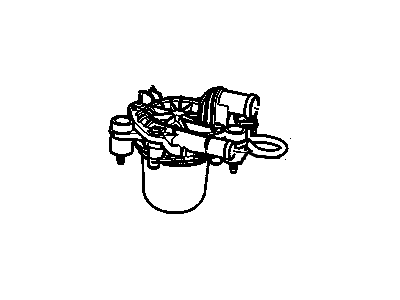

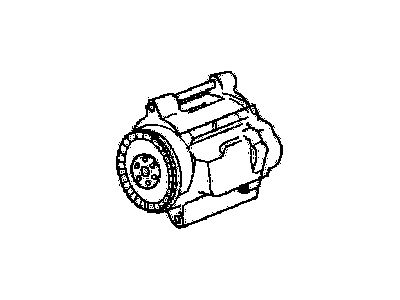

Genuine Pontiac Grand Prix Secondary Air Injection Pump

Secondary Smog Air Injection Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

10 Secondary Air Injection Pumps found

Pontiac Grand Prix Pump Assembly, Secondary Air Injection

Part Number: 12568241$145.22 MSRP: $455.06You Save: $309.84 (69%)Ships in 1-2 Business DaysPontiac Grand Prix Pump Assembly, Secondary Air Injection (W/ Bracket)

Part Number: 12584904$212.82 MSRP: $434.14You Save: $221.32 (51%)Ships in 1-2 Business DaysPontiac Grand Prix Pump Assembly, Secondary Air Injection (W/ Bracket)

Part Number: 12597245$136.22 MSRP: $277.86You Save: $141.64 (51%)Ships in 1-2 Business DaysPontiac Grand Prix Pump Asm,Secondary Air Injection

Part Number: 7835397$171.33 MSRP: $329.48You Save: $158.15 (48%)

Pontiac Grand Prix Secondary Air Injection Pump

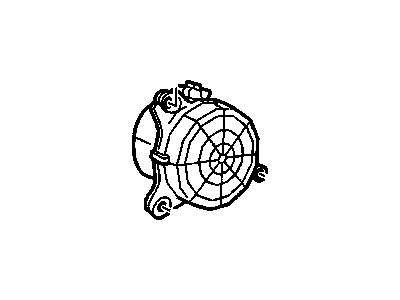

Secondary Air Injection Pump involved on Pontiac Grand Prix vehicles is the part of Air Injection Reactor (AIR) system where fresh air is injected into exhaust system with purpose of mandatory oxidation of fuel which has not been burned and reduction of emission of some dangerous products such as HC or CO. It commonly comprises an electric or belt-driven air pump, an air control valve, and a range of check valves that in combination control the flow of air, in relation to temperature and operations of the engine. The pump produces pressured air which is forwarded to the exhaust ports during the engine warm up to reduce on emissions from an excess air/fuel mixture. After engine attains normal working temperature it will supply air to the catalytic converter for the emission control. In most of the models of the Pontiac Grand Prix, there can be variations in Secondary Air Injection Pumps and its working and some of the components may include a diverter valve which is used to control backfires in instances that the car is in the process of deceleration. Maintenance of Secondary Air Injection Pump is very important to ensure that the vehicle operates with efficiency as well as meeting the set emissions requirements.

Each OEM Pontiac Grand Prix Secondary Air Injection Pump we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Grand Prix Secondary Air Injection Pump Parts Questions & Experts Answers

- Q: How to Diagnose and Replace Drive Belt,Secondary Air Injection Check Valve and Secondary Air Injection Pump on Pontiac Grand Prix?A:The operate known as AIR system is implemented in all models that use the V6 engine and manual transaxles to lessen the hydrocarbons and carbon monoxide chucked out by the engine's exhaust by hitting an air injector into the exhaust ports of each of the cylinders. Using an air pump, it discharges air into the exhaust stream; an Electric Air Control (EAC) valve controlled by the Electronic Control Module (ECM) regulates the discharge of air in conformity with the temperature of the engine and the general driving conditions of the vehicle. During deceleration, all the air is directed to the atmosphere, so as to avoid back firing. A check valve to its exhaust stream is another feature of the system to avoid backflow return. There are an engine-driven air pump; an EAC valve; air hoses; a check valve; and from 2007-electrically driven pump. Since it is a system, it may be somewhat difficult in identifying problems, however, the parts of the system can be examined. Inspections should being with hoses and wire checks whereby they are checked to ensure that they are in good condition. The pump can be tested by using the engine with normal temperature and using mouth to try to suck air from the pump hose. Check valve must permit air flow in only one direction, while vacuum at the air control valve must also be checked. In the case of component replacement, to adjust or replace pump drivebelt, bolts are to be loosened and the pump has to be removed. AIR pump pulley and filter is easily serviceable by compressing the drivebelt and removing the bolts on the pulley; however, when replacing the filter, one must avoid causing overhead damage to the pump housing. Most of the hoses and tubes must first be removed and then replaced with new ones made of the same type of material and with approximately the same dimensions as the old ones; the check valve can be replaced simply by disconnecting it from the assembly. The EAC valve is designed to be replaced by disconnecting the battery and subsequently, all hoses and connectors connected to the valve. The AIR pump can be removed by freeing the drivebelt and removing mounting bolts; AIR pump installation is to be done in reverse order with attention being paid on the tension of the drivebelt.

Related Pontiac Grand Prix Parts

Browse by Year

2008 Secondary Air Injection Pump 2007 Secondary Air Injection Pump 2006 Secondary Air Injection Pump 2005 Secondary Air Injection Pump 2003 Secondary Air Injection Pump 2002 Secondary Air Injection Pump 2001 Secondary Air Injection Pump 2000 Secondary Air Injection Pump 1996 Secondary Air Injection Pump 1993 Secondary Air Injection Pump 1992 Secondary Air Injection Pump 1991 Secondary Air Injection Pump 1990 Secondary Air Injection Pump 1989 Secondary Air Injection Pump 1988 Secondary Air Injection Pump 1987 Secondary Air Injection Pump 1986 Secondary Air Injection Pump 1985 Secondary Air Injection Pump 1984 Secondary Air Injection Pump 1983 Secondary Air Injection Pump 1982 Secondary Air Injection Pump