My Garage

My Account

Cart

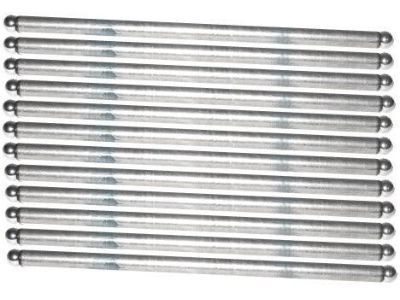

Genuine Pontiac Pushrod

Valve Push Rod- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

27 Pushrods found

Pontiac Rod,Valve Push

Part Number: 10238852$18.68 MSRP: $30.90You Save: $12.22 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: ROD, Engine Valve Push Rod; Push Rod

Pontiac Rod Assembly, Valve Push

Part Number: 12577692$9.65 MSRP: $15.39You Save: $5.74 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: ROD, Engine Valve Push Rod; Push Rod

Pontiac Rod Assembly, Valve Push

Part Number: 12577693$15.36 MSRP: $25.42You Save: $10.06 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: ROD, Engine Valve Push Rod; Push Rod

Pontiac Rod Assembly, Valve Push

Part Number: 10241740$14.89 MSRP: $23.75You Save: $8.86 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: ROD, Engine Valve Push Rod; Push Rod

Pontiac Rod Assembly, Valve Push

Part Number: 476525$17.46 MSRP: $18.97You Save: $1.51 (8%)Ships in 1-2 Business DaysProduct Specifications- Other Name: ROD; Push Rod

Pontiac Rod Assembly, Valve Push

Part Number: 14095256$16.76 MSRP: $26.37You Save: $9.61 (37%)Ships in 1-3 Business DaysProduct Specifications- Other Name: ROD; Push Rod

- Product Specifications

- Other Name: ROD, Engine Valve Push Rod; Push Rod

- Product Specifications

- Other Name: ROD, Engine Valve Push Rod; Push Rod

- Product Specifications

- Other Name: ROD, Engine Valve Push Rod; Push Rod

- Product Specifications

- Other Name: ROD, Engine Valve Push Rod; Push Rod

- Product Specifications

- Other Name: ROD, Engine Valve Push Rod; Push Rod

Pontiac Rod,Valve Push

Part Number: 10046173$12.05 MSRP: $19.20You Save: $7.15 (38%)Ships in 1-3 Business DaysProduct Specifications- Other Name: ROD, Engine Valve Push Rod; Push Rod

Pontiac Rod, Valve Push

Part Number: 24504406$10.72 MSRP: $17.74You Save: $7.02 (40%)Ships in 1-3 Business DaysProduct Specifications- Other Name: ROD, Engine Valve Push Rod; Push Rod

Pontiac Rod Assembly, Valve Push

Part Number: 24575409$5.31 MSRP: $14.49You Save: $9.18 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: ROD, Engine Valve Push Rod; Push Rod

Pontiac Rod Assembly, Valve Push (144Mm) *Yellow Inside Diameter

Part Number: 10166354$3.98 MSRP: $6.27You Save: $2.29 (37%)Product Specifications- Other Name: ROD, Engine Valve Push Rod; Intake Push Rod, Push Rod

Pontiac Rod Assembly, Valve Push (152Mm) *Gree*Green Inside Diameter

Part Number: 10166355$3.94 MSRP: $6.20You Save: $2.26 (37%)Product Specifications- Other Name: ROD, Engine Valve Push Rod; Exhaust Push Rod, Push Rod

- Product Specifications

- Other Name: ROD, Engine Valve Push Rod; Push Rod

- Product Specifications

- Other Name: ROD, Engine Valve Push Rod; Push Rod

- Replaces: 12599951

- Product Specifications

- Other Name: ROD, Engine Valve Push Rod; Push Rod

- Product Specifications

- Other Name: ROD, Engine Valve Push Rod; Push Rod

| Page 1 of 2 |Next >

1-20 of 27 Results

Pontiac Pushrod

If you're searching for OEM Pontiac Pushrods, look no further. Our website boasts an extensive inventory of genuine Pontiac Pushrods, all available at competitive prices online. Every part we offer comes with a manufacturer's warranty. In addition, we provide a straightforward return policy and rapid delivery services, making your shopping experience a breeze.

Pontiac Pushrod Parts Questions & Experts Answers

- Q: How to remove and reinstall the Pushrod and Rocker Arm in 2.2L four cylinder engine on Pontiac Grand Prix?A:To eliminate the valve cover from the cylinder head, turn the rocker arm nuts at the frontal part of the cylinder head counterclockwise; to remove the pushrods only, the rocker arms must be turned sideways The rocker arm nuts, the pivot balls, and the rocker arms must be removed if all the parts are affected. In case only the pushrods are being removed, turn the rocker arms in a way that will enable the pushrods to be removed. All the nuts, the rocker arms and the pivot balls should be placed in containers that are properly labeled so that they can be fitted back in the right positions, the box in which the pushrods are placed should have perforations, and with writing on the box that indicates the front side of the engine. If the pushrod guides need to be removed one must mark them in order to know how to install them later. The common areas to look for defects in a rocker arm are wear, crack and damage especially at the part that may touch the pushrods and valve stem; make sure the hole at the end of the pushrods is also clear. Inspect the pivot location of each of the rocker arm for signs of wear or damage; replace any worn or damaged rocker arm or its pivot balls. Examine the pushrods for cracks and excessive wear, take each and roll it across a piece of plate glass and this will show any bending. During reassembly, apply clean engine oil or moly-base grease to the low ends of the pushrods before they are reinstalled to their prior positions and make sure they are firmly seated in the lifter shelf. Having placed the adjusting end of each pushrod over the upper end of the respective rocker arm, and having inserted the nut over each pushrod, you must then smear moly-base grease on the end of the valve stems and on the upper ends of the pushrods before you fit the rocker arm nuts. Fit the rocker arm assemblies onto the heads in the locations specified, fit the pivot balls into the holes in the rocker arms along with the nuts to secure it, using moly-base grease to protect the mating surfaces until such a point that adequate engine oil pressure is unavailable, then tighten all nuts to the prescribed torque.