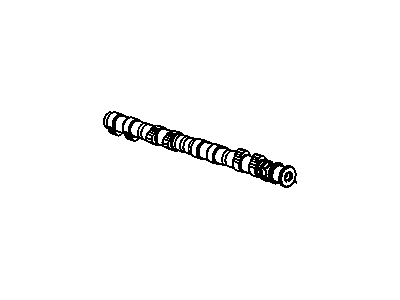

To remove the camshaft from the rear cylinder head, first relieve the fuel system pressure. Next, remove the valve covers, followed by the timing belt, and then the rocker arms/shafts as an assembly. It is important to check camshaft end play before proceeding. After that, remove the camshaft sprockets and the battery, disconnect the wire harness retainers from the fuse block, release the plastic clips, lift the fuse block, and move it to the rear. Remove the battery tray, drain the coolant, and take off the upper radiator hose. Remove the EGR valve, then either remove the under hood fuse box or position it out of the way, disconnect the interfering engine wiring harness connectors, and move the harnesses aside. Disconnect the fuel supply line at the fuel rail. For both camshafts, remove the camshaft retainer plate and its O-ring, then carefully slide the camshaft out of the cylinder head, ensuring not to nick the bearings. During inspection, keep track of the components' locations, remove the rocker arms and springs from the rocker shafts, and bolt the bare rocker shafts to the cylinder head, tightening them to the specified torque. Mount a dial indicator to contact the nose of the camshaft and pry the camshaft forwards and back, recording the movement. If the end play is excessive, install a new retainer plate and check again; if still excessive, the camshaft must be replaced. Remove the retainer plate and slide the camshaft out, measuring the journal diameters and lobe heights while checking for visual signs of wear. The camshaft oil seal should be replaced whenever a camshaft is removed or replaced, so remove the timing belt rear covers to access the seals, pry out the old seal, lubricate the lips with engine oil, and install a new seal squarely to the same depth as the original. Clean the camshaft with solvent, lubricate the journals and lobes with camshaft installation lubricant, and carefully install the camshaft into the cylinder head. Lubricate and install a new O-ring on the camshaft retainer plate, install the retainer plate, and tighten the bolts to the specified torque. Reinstall the remaining components in reverse order of removal, refill the cooling system if it was drained, and run the engine at low speed for five minutes to allow air to bleed from the lost motion assemblies, checking for leaks and proper operation. Some tappet noise may occur during the first few minutes of operation, and if it continues, it may indicate a problem with one of the lost motion assemblies.

Posted by GMPartsGiant Specialist