My Garage

My Account

Cart

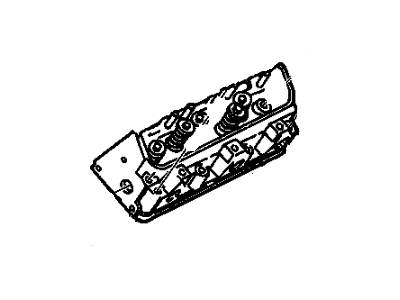

Genuine 1995 Pontiac Grand Prix Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Cylinder Heads found

- Product Specifications

- Other Name: Head,Cyl

- Item Weight: 14.90 Pounds

- Item Dimensions: 9.0 x 8.9 x 17.0 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 10154745

- Warranty: This genuine part is guaranteed by GM's factory warranty.

- Product Specifications

- Other Name: Head Assembly, Cyl (Machining); Cylinder Head

- Item Weight: 18.20 Pounds

- Item Dimensions: 19.7 x 10.9 x 5.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- Require Quantity: 2

- SKU: 10162077

- Warranty: This genuine part is guaranteed by GM's factory warranty.

1995 Pontiac Grand Prix Cylinder Head

We are your prime source for competitively priced and high-quality OEM 1995 Pontiac Grand Prix Cylinder Head. We provide you with parts that will allow you to save a lot of money without sacrificing quality. All our OEM parts are backed by the manufacturer's warranty and shipped out at a swift rate.

1995 Pontiac Grand Prix Cylinder Head Parts Questions & Experts Answers

- Q: What steps should be taken for thorough cleaning and inspection of cylinder heads and valve train components during an engine overhaul on 1995 Pontiac Grand Prix?A: Cleaning the cylinder heads and other related to them valve train parts and their subsequent, very accurate, inspection will allow to make decision concerning required valve service work at the course of the engine rebuilding. First, remove all the gasket material and sealant and the head gasket, intake manifold, and exhaust manifold, but use a way that does not harm the cylinder head. Scrub the accumulation of scale from the coolant passages as well as use stiff wire brush to clean the various holes. Insert an appropriate size tap to each threaded hole to remove corrosion and any thread sealant; use compressed air to blow out interior of fitting; protect eyes. Scrub the spline of the rocker arm pivot stud with a wire brush, followed by cleaning the cylinder head with solvent and making sure that you dry it-you might use compressed air to facilitate the drying. It may therefore be useful to decarbonize chemicals but this should be done under certain conditions. The rocker arms, the pivot balls, the nuts and the pushrods must be cleaned using solvent, but before washing the solvent should be dried with out rubbing them together. The valve spring, spring seat, rotators, keepers, and retainers of the single valve should be cleaned at once so that none of the parts of the various valves get mixed up. Scrape off large concentrations of deposits from the valves with a motorized wire brush while trying to avoid cross connection between them. Check the head for cracks, leaks and other signs of damage and, if in doubt, consult an automotive machine shop. Verify the head gasket mating surface for warpage with either a straightedge and a feeler gauge or by using a mirror, and look for signs of valve seat pitting, cracking, or burning. With the valve still in the cylinder, use a dial indicator to check the valve stem to guide clearance, if one is concerned about the valve guides, take the engine to a machine shop for evaluation. Check for wear of deformation and cracks that may be present on any of the valve face and compute for the average margin width for all faces; replace valves that may be below the specified limit. Inspect each valve spring for its serviceability in wear limit, free length, to the prescribed specifications and the squareness of each spring. Investigate the conditions of the spring retainers and keepers especially in term of their wear and cracking and replace any part that is questionable. Lever components, the wear and crack of which are possible, should be evaluated, while the push-rod ends may show signs of scuffing; rocker arm studs must be tight. Both damaged and 'worn out' sections need to be replaced. In the event the inspection shows that some of the valves require servicing, rearrange them within the cylinder head as spares.