My Garage

My Account

Cart

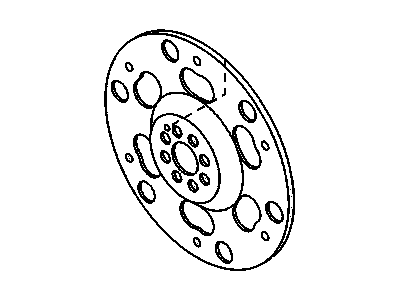

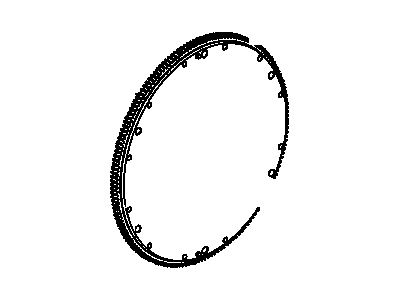

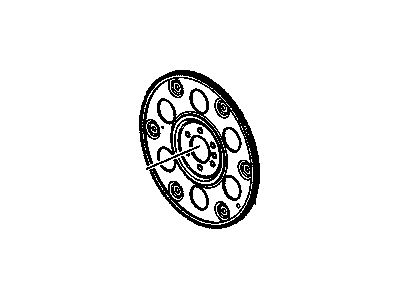

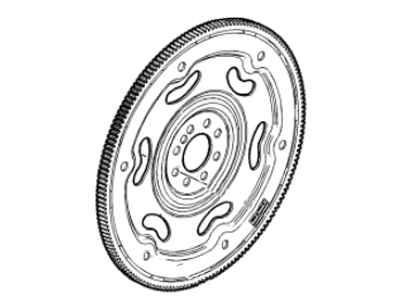

Genuine Cadillac Escalade Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

17 Flywheels found

Cadillac Escalade Automatic Transmission Flexible Plate Assembly

Part Number: 12654640$132.41 MSRP: $226.41You Save: $94.00 (42%)Cadillac Escalade Automatic Transmission Flexible Plate Assembly (3 Bolt Converter)

Part Number: 12620099$68.10 MSRP: $116.44You Save: $48.34 (42%)Ships in 1-2 Business DaysCadillac Escalade Engine Crankshaft FLYWHEEL

Part Number: 19260102$86.99 MSRP: $148.77You Save: $61.78 (42%)Ships in 1-2 Business DaysCadillac Escalade Engine Crankshaft Flywheel

Part Number: 14088761$139.38 MSRP: $230.69You Save: $91.31 (40%)Ships in 1-2 Business DaysCadillac Escalade Engine Crankshaft Flywheel

Part Number: 12561680$383.36 MSRP: $611.43You Save: $228.07 (38%)Cadillac Escalade Automatic Transmission Flexible Plate

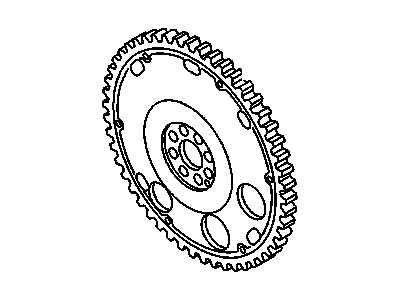

Part Number: 12621644$226.51 MSRP: $374.89You Save: $148.38 (40%)Ships in 1-3 Business DaysCadillac Escalade Engine Crankshaft Flywheel

Part Number: 24238864$528.93 MSRP: $875.06You Save: $346.13 (40%)Ships in 1-3 Business DaysCadillac Escalade Engine Crankshaft Flywheel

Part Number: 12561217$359.56 MSRP: $595.10You Save: $235.54 (40%)Ships in 1-3 Business DaysCadillac Escalade Plate Assembly, Automatic Transmission Flexible

Part Number: 12685003$59.81 MSRP: $103.17You Save: $43.36 (43%)Cadillac Escalade Engine Crankshaft Flywheel

Part Number: 12557585$421.38 MSRP: $605.96You Save: $184.58 (31%)Ships in 1-2 Business DaysCadillac Escalade Automatic Transmission Flexible Plate Assembly

Part Number: 55490601$34.65 MSRP: $57.33You Save: $22.68 (40%)Ships in 1-3 Business DaysCadillac Escalade Engine Crankshaft Flywheel

Part Number: 12582964$204.61 MSRP: $326.20You Save: $121.59 (38%)Ships in 1-3 Business DaysCadillac Escalade Engine Crankshaft FLYWHEEL

Part Number: 97378429$297.08 MSRP: $469.55You Save: $172.47 (37%)

Cadillac Escalade Flywheel

Each OEM Cadillac Escalade Flywheel we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac Escalade Flywheel Parts Questions & Experts Answers

- Q: How to properly remove and reinstall a flywheel from a crankshaft in V6 engine on Cadillac Escalade?A:Lift the vehicle and then support it on jackstands after which remove the transmission. Put a marker on the driveplate and the crankshaft, afterwards unbolt the bolts that connected the driveplate to the crankshaft. In the case where the crankshaft rotates, slot the drive plate and then jam a screwdriver horizontally into the ring gear teeth. Because of its weight, the driveplate should be supported when the final bolt has been unscrewed; proceed to unscrew the bolts carefully. Wipe clean the driveplate to remove any grease and oil, examining the same carefully for signs of cracks or worn out ring gear teeth, then placing the same on a flat surface to see if it is warped. Check and have the mating surfaces of the driveplate and crankshaft cleaned and if the rear main oil seal is leaking then it should be replaced before the driveplate is reinstalled. Replace the driveplate on the crankshaft in similar fashion to the removal process while centering the part by matching up of marks and proper fitment should be possible using any alignment dowel or a staggered bolt pattern. Cover the threads on the bolt by applying the thread locking compound and ensure then you have positioned the retaining ring on the drive plate while tightening the bolts just up to the recommended torque, you use a screw driver to hold down the teeth of the ring gear to avoid any movement. If the transmission front pump seal or O-ring is damaged or worn it should be replenished at this time. The rest of the installation is the exact opposite of the removal process that has been explained above.

Related Cadillac Escalade Parts

Browse by Year

2024 Flywheel 2023 Flywheel 2022 Flywheel 2021 Flywheel 2020 Flywheel 2019 Flywheel 2018 Flywheel 2017 Flywheel 2016 Flywheel 2015 Flywheel 2014 Flywheel 2013 Flywheel 2012 Flywheel 2011 Flywheel 2010 Flywheel 2009 Flywheel 2008 Flywheel 2007 Flywheel 2006 Flywheel 2005 Flywheel 2004 Flywheel 2003 Flywheel 2002 Flywheel 2000 Flywheel 1999 Flywheel