My Garage

My Account

Cart

Genuine Cadillac Escalade Oxygen Sensor

Oxygen O2 Sensor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

26 Oxygen Sensors found

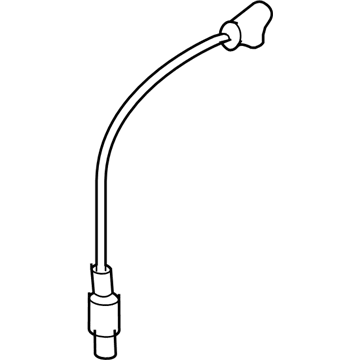

Cadillac Escalade Sensor Assembly, Heated Oxygen(Pre, Catalyst Bank 1 Se)

Part Number: 12659516$56.05 MSRP: $114.34You Save: $58.29 (51%)Ships in 1-2 Business DaysCadillac Escalade Sensor Assembly, Heated Oxygen (Pre, Catalyst Bank 2 S)

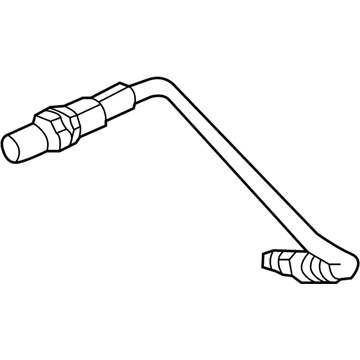

Part Number: 12666673$44.37 MSRP: $90.52You Save: $46.15 (51%)Ships in 1-2 Business DaysCadillac Escalade Sensor Assembly, Heated Oxygen (Position 3)

Part Number: 12609457$50.13 MSRP: $102.26You Save: $52.13 (51%)Ships in 1-2 Business DaysCadillac Escalade Sensor,Heated Oxygen(Position 2)

Part Number: 12589321$72.09 MSRP: $147.08You Save: $74.99 (51%)Ships in 1-3 Business DaysCadillac Escalade Heated Oxygen Sensor Assembly (Position 2)

Part Number: 12583804$57.06 MSRP: $116.40You Save: $59.34 (51%)Ships in 1-2 Business DaysCadillac Escalade Sensor,Heated Oxygen(Position 2)

Part Number: 12572705$90.09 MSRP: $183.78You Save: $93.69 (51%)Ships in 1 Business DayCadillac Escalade Heated Oxygen Sensor Assembly (Position 3)

Part Number: 19209808$72.08 MSRP: $147.04You Save: $74.96 (51%)Ships in 1-2 Business DaysCadillac Escalade Sensor,Heated Oxygen(Position 2)

Part Number: 12587785$50.37 MSRP: $102.74You Save: $52.37 (51%)Ships in 1-2 Business DaysCadillac Escalade Heated Oxygen Sensor Assembly (Position 3)

Part Number: 19209812$78.26 MSRP: $147.66You Save: $69.40 (47%)Ships in 1-2 Business DaysCadillac Escalade Sensor Assembly, Htd Oxy (Post, Catalyst Bank 1)

Part Number: 12670253$39.57 MSRP: $80.72You Save: $41.15 (51%)Ships in 1 Business DayCadillac Escalade Sensor Assembly, Htd Oxy (Pre, Catalyst Bank 2 S)

Part Number: 12687606$40.88 MSRP: $83.40You Save: $42.52 (51%)Ships in 1-2 Business DaysCadillac Escalade Sensor,Heated Oxygen(Position 1)

Part Number: 12576131$51.36 MSRP: $104.78You Save: $53.42 (51%)Ships in 1-2 Business DaysCadillac Escalade Sensor Assembly, Heated Oxygen

Part Number: 12562943$62.02 MSRP: $126.52You Save: $64.50 (51%)Ships in 1 Business DayCadillac Escalade Sensor Assembly, Heated Oxygen

Part Number: 12565397$67.45 MSRP: $137.61You Save: $70.16 (51%)Ships in 1-2 Business DaysCadillac Escalade Sensor Asm,Heated Oxygen (Position 2)

Part Number: 19178961$61.16 MSRP: $124.77You Save: $63.61 (51%)Ships in 1 Business DayCadillac Escalade Sensor Asm,Heated Oxygen

Part Number: 19178934$71.75 MSRP: $146.38You Save: $74.63 (51%)Ships in 1-2 Business DaysCadillac Escalade Sensor Assembly, Htd Oxy(Pre, Catalyst Bank 1 Se)

Part Number: 12668435$36.35 MSRP: $74.16You Save: $37.81 (51%)Cadillac Escalade Heated Oxygen Sensor Assembly

Part Number: 19355306$57.29 MSRP: $116.86You Save: $59.57 (51%)Ships in 1-2 Business DaysCadillac Escalade Sensor Assembly, Heated Oxygen

Part Number: 12565415$54.56 MSRP: $170.94You Save: $116.38 (69%)Ships in 1-2 Business DaysCadillac Escalade Heated Oxygen Sensor Assembly (Position 3)

Part Number: 19209815$101.72 MSRP: $182.46You Save: $80.74 (45%)

| Page 1 of 2 |Next >

1-20 of 26 Results

Cadillac Escalade Oxygen Sensor

The Oxygen Sensor on Cadillac Escalade vehicles is responsible for measuring the levels of the remaining oxygen in the exhaust gases, it enables optimization of air to fuel ratio as well as reducing the emission of gases. It provides a voltage signal in relation to the oxygen levels and the engine control computer is able to alter the fuel injector timing as a result. Most Cadillac Escalade models have at least two oxygen sensors, the first is located upstream of the catalytic converter, and the second checks the efficiency of the converter. Cadillac Escalade cars over the recent past have incorporated both the standard type of zirconia oxide oxygen sensors and the modern air to fuel ratio sensors. While traditional sensors offer a set of narrow bands which supplied signals to the ECU as to whether the mixture was rich or lean, the AF ratio sensor supplied a broad range of data for the handling of fuel mixture. Contamination and actual degradation over a period of time using up the special features and deteriorating the effectiveness of controlling emission. Oxygen Sensor requires to be checked frequently for it plays essential role in the Cadillac Escalade's engine system as is known.

Each OEM Cadillac Escalade Oxygen Sensor we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac Escalade Oxygen Sensor Parts Questions & Experts Answers

- Q: How does an oxygen sensor function as a galvanic battery to maintain the ideal air/fuel ratio for optimal catalytic converter performance on Cadillac Escalade?A:An oxygen sensor is a galvanic battery that produces a current output proportional to the oxygen concentration in exhaust gases; it supplies the PCM with essential feedback to sustain the air/fuel equimolar of 14.7:1 to optimise operation of Catalytic Converter. On-Board Diagnostics II (OBD-II) engine management system fitted vehicles utilise two oxygen sensors, one pre and post catalytic converter to compare the efficiency of oxygen levels in the exhaust gas. All the models have four heated oxygen sensors, namely, cylinder bank sensors located on the exhaust pipe assembly and under the vehicle, each containing an upstream and downstream sensor. These sensors are heated to shorten the warm-up time the PCM actuates the heater circuit to provide correct voltage signal once the sensors are at operating temperature. Whenever it is being serviced, care must be taken since the sensors have permanently attached pigtails and electrical connectors that are very much vulnerable to damage, contamination, and mishandling. As for procedures of working with sensors, it is desirable to warm the engine when replacing the sensor because it makes it easy to remove, and the procedure includes the next steps: disconnect the electrical connector, unscrew the sensor with the help of a suitable sockets, apply anti-seize compound if the old sensor is used again, and check the tightness of the screws.

Related Cadillac Escalade Parts

Browse by Year

2024 Oxygen Sensor 2023 Oxygen Sensor 2022 Oxygen Sensor 2021 Oxygen Sensor 2020 Oxygen Sensor 2019 Oxygen Sensor 2018 Oxygen Sensor 2017 Oxygen Sensor 2016 Oxygen Sensor 2015 Oxygen Sensor 2014 Oxygen Sensor 2013 Oxygen Sensor 2012 Oxygen Sensor 2011 Oxygen Sensor 2010 Oxygen Sensor 2009 Oxygen Sensor 2008 Oxygen Sensor 2007 Oxygen Sensor 2006 Oxygen Sensor 2005 Oxygen Sensor 2004 Oxygen Sensor 2003 Oxygen Sensor 2002 Oxygen Sensor 2000 Oxygen Sensor 1999 Oxygen Sensor