My Garage

My Account

Cart

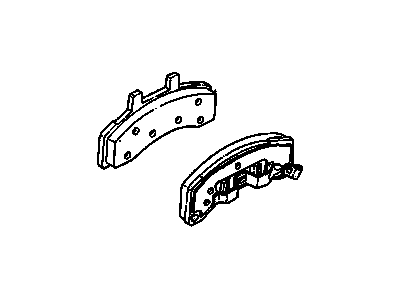

Genuine Cadillac Fleetwood Brake Pad

Disc Brake Pad Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Brake Pads found

Cadillac Fleetwood Front Disc Brake Pad Kit

Part Number: 89026844$54.18 MSRP: $141.22You Save: $87.04 (62%)Ships in 1-3 Business Days

Cadillac Fleetwood Brake Pad

Brake pads are parts of Cadillac Fleetwood vehicle braking systems whereby energy of motion is transformed to thermal energy through friction of pads on the brake rotors thus slowing down the vehicle. These brake pads are usually a blend of metals and engineering synthetics guaranteeing high thermal conductivity to resist thermal degradation which comes about from high temperatures that the pads operate in. Through the years, Cadillac Fleetwood has used different types and kinds of brake pads: the non-metallic, the semi-metallic, fully metallic and the ceramic types, all of which has its different friction co-efficiency, wear and tear resistance and noise factor. Maintenance of a car is important and usually, the brake pad wears out within 50, 000miles and there is usually a wear sensor and indicator that poses a reminder to the driver that it is time for change. Correct fitting of the brake pads, as well as other related hardware is important in improving the performance as well as life of Cadillac Fleetwood vehicles.

Each OEM Cadillac Fleetwood Brake Pad we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac Fleetwood Brake Pad Parts Questions & Experts Answers

- Q: How to remove and install disc brake pads safely and effectively on Cadillac Fleetwood?A:To remove and install disc brake pads, avoid inhaling dust from brake surfaces and use a commercially available brake cleaning fluid. Replace disc brake pads in axle sets only. Begin by using a syringe to remove two-thirds of the brake fluid from the master cylinder reservoir, then raise and safely support the vehicle. Remove the wheel and tire assembly, reinstalling two lug nuts to retain the disc brake rotor. Detach the disc brake caliper from the mounting bracket without disconnecting the brake hose, and suspend the caliper with wire from the coil spring. Use a small prybar to disengage the buttons on the outboard disc brake pad from the caliper housing and remove it, followed by the inboard disc brake pad. Inspect the disc brake rotor and machine or replace as necessary. For installation, clean the caliper piston boot with denatured alcohol, then use a C-clamp to bottom the caliper piston into the bore, ensuring not to damage it. After bottoming the piston, use a small tool to lift the inner edge of the boot and press out any trapped air. Install the inboard disc brake pad by snapping the retainer spring into the piston, ensuring it lays flat and does not touch the boot. Next, install the outboard disc brake pad, positioning the wear sensor correctly based on the vehicle model. Reinstall the disc brake caliper, followed by the wheel and tire assembly, and lower the vehicle. Apply the brake pedal several times to position the caliper piston and seat the brake pads, then check the brake fluid level and add as necessary. For inspection, check the disc brake pads every 6000 miles or whenever the wheels are removed, focusing on both ends of the outer pad and the inner pad through the caliper. Replace pads when any lining thickness is worn to within 1/22 in. (0.76mm) of the backing plate or rivet, and note that the outer pad has a wear sensor that produces a warning noise when replacement is necessary.