My Garage

My Account

Cart

Genuine Cadillac Fleetwood Brake Disc

Disc Rotor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Brake Discs found

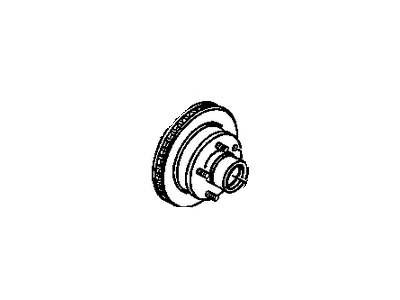

Cadillac Fleetwood Front Brake Rotor Assembly

Part Number: 19174917$47.46 MSRP: $89.54You Save: $42.08 (47%)Ships in 1-3 Business Days

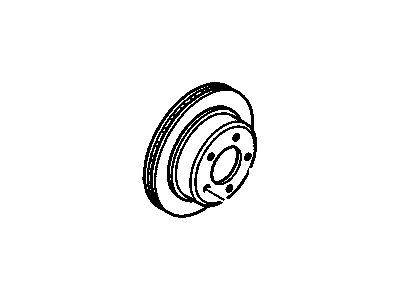

Cadillac Fleetwood Brake Disc

Cadillac Fleetwood car manufacturers equip their cars with a Brake Disc that is instrumental in the disc brake system as it affords the necessary surface on which the brake pads can apply the braking force. Screwed on the axle or hub, the Cadillac Fleetwood Brake Disc turns together with the wheel, and hydraulic pressure provided by the calipers presses the pads on the rotor to brake the vehicle. In the recent past Cadillac Fleetwood has embraced different kinds of Brake Discs, the solid and the vented. Standard rotors are vented and are equipped with cooling fins, they are much better in dissipating heat as opposed to solid rotors, which are seen from smaller models and those that lack performance. It is critical due to such problems as scoring, warping, or even an excessive runout Some Brake Discs have to be inspected frequently and replaced accordingly to Brake Discs in order to provide safe and stable braking.

Each OEM Cadillac Fleetwood Brake Disc we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac Fleetwood Brake Disc Parts Questions & Experts Answers

- Q: How to remove and install front Brake Disc on Cadillac Fleetwood?A:Before you start, lift the car safely and take out the tire and wheel together. After taking off the brake caliper, hold it above the ground using a wire through the coil spring. Keep the brake hose away from the weight. When you have them, take off the wheel studs' retainers and throw them away because you won't use them again. After you take out the disc brake rotor, examine it, and either fix with fine work or buy new parts. Press the rotor onto the truck's wheel studs and hub handle before hanging the brake caliper in place. After that, put the wheel and tire together and let the vehicle go back down to the ground. Check the rotor surface condition for any brown discolorations from overheating or shiny and thin (glazed) areas, along with gouges; if spotted, you must repair it through machine work. Scoring under 0.050 inches (1.2 millimeters) is usually allowed, but heavy scores need refinish work that matches strict minimum thickness rules. Check how evenly the rotor is built up. Too much difference in thickness can cause the brake pedal to shake or bounce when pressed. Measure the rotor's thickness at different spots around its edge, and make sure you test the same point about 1 inch from the rim each time. A rotor needs to be ground when it varies by more than 0.0005 in. (0.013mm) while following minimum thickness requirements must be followed. Look for uneven tire-to-wheel alignment that causes shaking when you brake, though you may not feel it through your foot. To find out if your wheel runs true, disconnect the tire, screw the wheel nuts back on, attach a dial gauge to the steering knuckle or caliper frame, and make sure its indicator tip touches the rotor's surface half to one inch away from the edge. Reset the indicator, let the rotor spin fully, and record any measurement on the dial. You can fix any extra movement by moving the hub along its wheel stud an extra turn or two. When indexing is not sufficient, check the hub and bearing assembly for side-to-side vibration or looseness. Replace the entire unit and check the rotor again if either exceeds 0.0015" in (0.040mm) on Deville and Fleetwood models. When lateral runout won't decrease enough, machine the rotor based on specific minimum thickness rules.