My Garage

My Account

Cart

Genuine Cadillac Fleetwood Brake Shoe

Brake Shoe Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Brake Shoes found

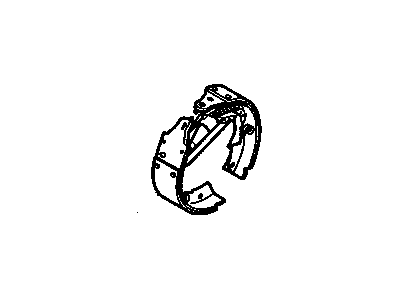

Cadillac Fleetwood Rear Brake Shoe Kit

Part Number: 19150002$112.49 MSRP: $221.23You Save: $108.74 (50%)Ships in 1-2 Business DaysCadillac Fleetwood Shoe,Front Brake

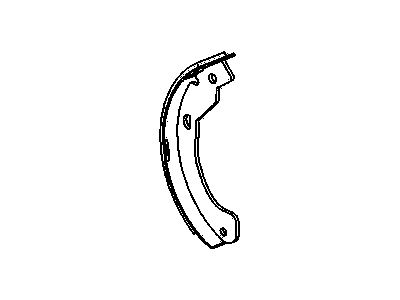

Part Number: 18029594$44.14 MSRP: $79.18You Save: $35.04 (45%)Ships in 1-3 Business Days

Cadillac Fleetwood Brake Shoe

Being the Brake Shoe of Cadillac Fleetwood a part of the drum brake system, these shoes are responsible for creating the required friction in order to stop the car. When brakes are pulled the shoes rub on the drum or the inner circumference to slow down the moving components. Cadillac Fleetwood models have incorporated a number of specifications of Brake Shoe such as the non-servo and the duo-servo. This means that the duo-servo configuration gives boost to the stopping power than the non-servo type of the rotating drum. Today drums are not used quite often, however, they can still be found due to their efficiency and good performance as parking brakes. Since the Brake Shoe can wear out over time and get contaminated which may result to change in performance, it should be inspected regularly. In sum, the Brake Shoe are critical parts of the Cadillac Fleetwood as they contribute to the smooth, safe, and reliable functioning of the vehicle.

Each OEM Cadillac Fleetwood Brake Shoe we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac Fleetwood Brake Shoe Parts Questions & Experts Answers

- Q: How should older brake pads or Brake Shoe containing asbestos be handled and maintained on Cadillac Fleetwood?A:Earlier Brake Pads or shoes may have used asbestos, a substance that has been classified as causing cancer; therefore, it is recommended not to blow clean the brake surface(s) with compressed air and not to inhale any dust on such surfaces at all; one should use brake cleaning fluid that is commercially available. Brake shoes must be checked every 6000 miles or when the wheels are off and, if the lining thickness is worn down to the backing plate or rivet by 1/32 inch (0.76mm) the shoes must be replaced in axle sets. For removal and installation, firstly, support the vehicle and then Assemble the wheel and tire, Assemble the Brake Drum. Disconnect the shock absorbers, springs and the other parts, lessen the Parking Brake Cable and see whether there are signs of wear or damage on the Wheel Cylinder. Ensure that the adjuster screw and the springs are properly placed when reconnecting the components after cleaning and lubricating where necessary. Slight adjust the brake so that the diameter is correct, then install the brake drum and the wheel, check parking brake adjustment. If there are modifications, make sure that the parking brake levers are placed properly and that the inside diameter of the brake drum is measured and the diameter of the brake shoe is adjusted before the assembling and testing of the mechanism.