My Garage

My Account

Cart

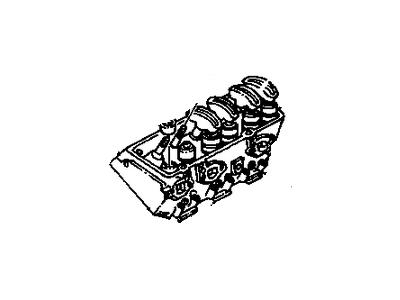

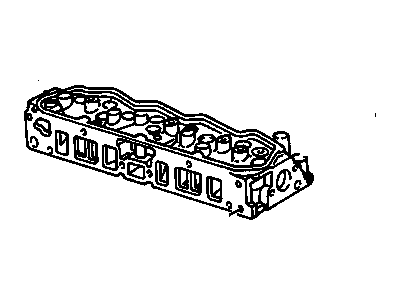

Genuine Chevrolet Astro Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Cylinder Heads found

Chevrolet Astro Cylinder Head Assembly (W/Studs)

Part Number: 12533558$310.73 MSRP: $491.12You Save: $180.39 (37%)Ships in 1-3 Business DaysChevrolet Astro Engine Cylinder Head

Part Number: 12555630$447.07 MSRP: $713.03You Save: $265.96 (38%)Ships in 1-3 Business DaysChevrolet Astro Cylinder Head Assembly

Part Number: 12558112$596.22 MSRP: $803.53You Save: $207.31 (26%)Ships in 1-3 Business Days

Chevrolet Astro Cylinder Head

Each OEM Chevrolet Astro Cylinder Head we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Astro Cylinder Head Parts Questions & Experts Answers

- Q: How to disassemble cylinder heads and valves on Chevrolet Astro?A:New or remanufactured cylinder heads can be easily bought from dealers or auto parts stores and it makes much more sense for do it yourself mechanics to just buy a new one to replace the originals rather than spending time and money to dismantle, inspect, and refurbish the heads. In disassembly, the intake and Exhaust Valves are removed together with other components. First, remove the nuts of the rocker arms, the pivot balls, and the rocker arms from the cylinder head studs making sure that the set parts are labeled in order to fit them again. If it is necessary to remove the valves, it will be useful to mark them and put them along with the parts in sets, so that it will be easy to return them to their places in the valve guides. Oversight the compressor on the first valve in order that one is capable of compressing it, afterwards, pull off the keepers, the retainer, the shield, springs and the spring seat. Take the O-ring seal off the valve stem and the umbrella type seal from the guide after which the valve is to be pulled out of the head. In case the valve binds apply force to the opposite direction and remove burr on the keeper groove area. Do the same to the other valves; assemble all parts needed for reinstallation in separate compartments. When valves and other components were removed and stored, the head should be washed, and other disassembly processes are to be done in case of a full engine rebuild before washing and physical assessment begins.

Related Chevrolet Astro Parts

Browse by Year

2005 Cylinder Head 2004 Cylinder Head 2003 Cylinder Head 2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1995 Cylinder Head 1994 Cylinder Head 1993 Cylinder Head 1992 Cylinder Head 1991 Cylinder Head 1990 Cylinder Head 1989 Cylinder Head 1988 Cylinder Head 1987 Cylinder Head 1986 Cylinder Head 1985 Cylinder Head