My Garage

My Account

Cart

Genuine Chevrolet Cruze Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Flywheels found

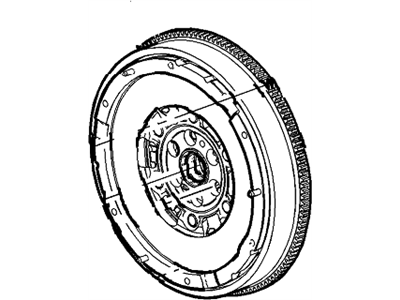

Chevrolet Cruze Engine Crankshaft FLYWHEEL

Part Number: 55584381$245.68 MSRP: $420.12You Save: $174.44 (42%)Ships in 1-2 Business DaysChevrolet Cruze Flywheel Assembly

Part Number: 55599020$220.53 MSRP: $380.40You Save: $159.87 (43%)Ships in 1-3 Business DaysChevrolet Cruze Automatic Transmission Flexible Plate Assembly

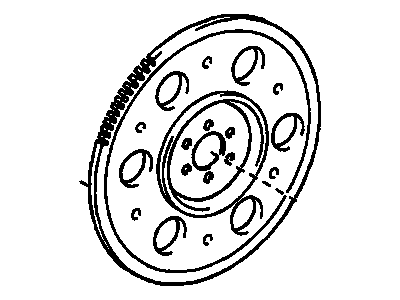

Part Number: 55573926$47.51 MSRP: $74.75You Save: $27.24 (37%)Ships in 1-3 Business DaysChevrolet Cruze Automatic Transmission Flexible Plate Assembly

Part Number: 55565760$58.75 MSRP: $93.69You Save: $34.94 (38%)Ships in 1-3 Business DaysChevrolet Cruze Automatic Transmission Flexplate

Part Number: 55570175$351.88 MSRP: $582.38You Save: $230.50 (40%)Ships in 1-3 Business DaysChevrolet Cruze Plate Assembly, Automatic Transmission Flexible

Part Number: 12638610$52.59 MSRP: $83.88You Save: $31.29 (38%)Chevrolet Cruze Plate Assembly, Automatic Transmission Flexible

Part Number: 55491928$50.18 MSRP: $83.05You Save: $32.87 (40%)Ships in 1-3 Business DaysChevrolet Cruze Automatic Transmission Flexible Plate Assembly

Part Number: 55587259$19.43 MSRP: $30.57You Save: $11.14 (37%)

Chevrolet Cruze Flywheel

Each OEM Chevrolet Cruze Flywheel we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Cruze Flywheel Parts Questions & Experts Answers

- Q: How to Remove and Install the Flywheel/Driveplate on Chevrolet Cruze?A:In order to eliminate the transaxle, one has to take it out and if there is a rattle, this is the proper time to consider setting up the front seal/C-ring on automatic transaxles. In manual transaxles, use a pressure plate and clutch disc and may want to inspect or renew the clutch parts. When removing/ separating the flywheel/driveplate and crankshaft mark the parts in same positions with a centre punch or paint whenever re assembly is required. Succeeding this, take out the fly wheel or the drive plate bolts using a screw driver in the ring gear to hold the crank shaft from rotating. Take out carefully the flywheel/driveplate by supporting it when the last bolt is being unscrewed with equal attention to the position of spacer if any is used. For installation, the flywheel must be cleaned to remove grease and oil, and then, the inspection of the flywheel for cracks and other related problems and the check on the warpage of the flywheel must be done by using a straight edge. The mating surface on a flywheel/driveplate must be clean and inspected, and the crankshaft rear seal, if it has leaks, must be replaced. Align the flywheel/driveplate to the crankshaft, replace any spacer and ensuring that you have the correct alignment by making use of alignment dowels or staggered bolt holes where any to be used. It is recommended that you apply a thread locking compound onto the threads of the bolt before proceeding to tighten it up to the required torque value reaching the latter incrementally. The rest of the aspects associated with installation process reflect the following logic: first, the steps which are the opposite of the removal procedure are followed.