My Garage

My Account

Cart

Genuine Chevrolet El Camino Piston Ring

Piston Ring Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Piston Rings found

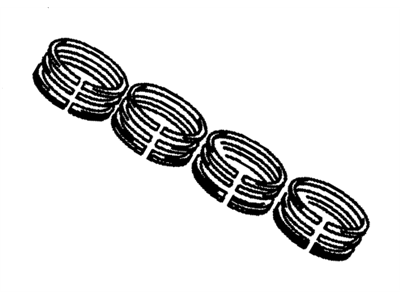

Chevrolet El Camino Ring Kit, Piston(5.0 Litre)

Part Number: 22529562$16.75 MSRP: $33.79You Save: $17.04 (51%)Chevrolet El Camino Ring Kit,Piston(Std)

Part Number: 25527543$17.70 MSRP: $35.70You Save: $18.00 (51%)Chevrolet El Camino Ring Unit, Piston(Std)

Part Number: 12518282$39.23 MSRP: $62.56You Save: $23.33 (38%)Ships in 1-2 Business Days

Chevrolet El Camino Piston Ring

The Piston Ring in Chevrolet El Camino is very important since it help to prevent the loss of gases in the combustion chamber, improves heat transfers and controls oil intake. These rings are generally forged out of cast iron or steel and while their main principle of operation is to minimize the contact surface area they need to sealing and friction which are important for the engine performance and durability. Chevrolet El Camino models have applied a wide range of Piston Rings over the years such as the cast iron and the thinner ones. The latest developments include, thinner rings for instance top and second rings that measure 1mm thereby minimizing friction and enhancing sealing and oil control. Such advancements enhance the flexibility of the piston rings making it easier to design a better piston and therefore an improved engine performance of the Chevrolet El Camino Piston Ring.

Each OEM Chevrolet El Camino Piston Ring we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet El Camino Piston Ring Parts Questions & Experts Answers

- Q: How should the piston and piston rings be installed for optimal engine performance in V8 engine on Chevrolet El Camino?A:The piston must be connected to the proper connecting rod and that needs to be done by a professional with the help and an arbor press. Piston rings should also be new and in the correct size to fit the piston being used and their fit is very important for the performance of the rebuilt engine. Before fitting piston rings, the ring end gap for each ring should be measured and the piston rings should be grouped into sets with a top ring, a second ring and an oil control three piece ring. Place one top ring approximately ¾-inch below the upper limit of ring travel and must be perpendicular with the cylinder bore by using the top portion of a piston. If with a feeler gauge, you cannot get the distance between the two ends of the ring sufficient, replace the present one with another top ring. Do the same for all other top rings and, if necessary, file the ends of them to shape. Also, it is important to measure the end gap of each second ring, as well as oil control rings. Refer to figures 3 and 4 and roll each piston ring on the piston to verify that none of the rings bind in their grooves; if the rings have been distorted, replace them. It is essential that the gaps are aligned correctly to the cylinder bore when installing the piston rings and this can be done with a piston ring expander if available or thin strips of tin if the expander is not available. Place the bottom oil ring spacer and its parts to specify the positions of the gaps for the steel oil ring rails. Last of all, inspect the fit of the piston rings into their grooves with the blade feeler gauge and rotate the piston around to make sure there is enough gap and replace or adjust the rings correspondingly.