My Garage

My Account

Cart

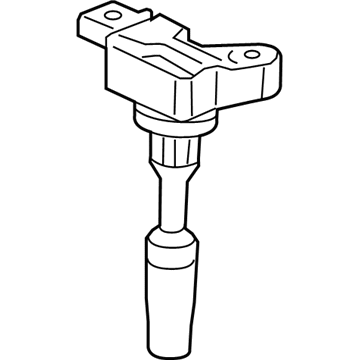

Genuine Chevrolet Ignition Coil

Ignition Coil Resistor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

73 Ignition Coils found

- Product Specifications

- Other Name: Coil Assembly, Ign; Coil, Ignition Coil

- Replaced by: 12739916

- Replaces: 12573190

Chevrolet Ignition Coil Assembly

Part Number: 25186687$74.32 MSRP: $243.94You Save: $169.62 (70%)Ships in 1 Business DayProduct Specifications- Other Name: Coil Assembly, Ignition; Ignition Coil

- Replaced by: 12735943

- Replaces: 96476983, 55561655

Chevrolet Coil Assembly, Ign

Part Number: 25202791$58.52 MSRP: $120.78You Save: $62.26 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Ignition Coil

- Replaces: 12654078, 12687140, 12652405

Chevrolet COIL ASM,IGN

Part Number: 19418993$60.73 MSRP: $114.58You Save: $53.85 (47%)Ships in 1 Business DayProduct Specifications- Other Name: Ignition Coil

- Replaces: 12558693, 19355500

Chevrolet COIL ASM,IGN

Part Number: 19418102$83.61 MSRP: $172.56You Save: $88.95 (52%)Ships in 1 Business DayProduct Specifications- Other Name: Ignition Coil, Spark Plug

- Replaces: 12583514, 12613057, 12629037

Chevrolet Ignition Coil Assembly

Part Number: 12673523$49.84 MSRP: $102.87You Save: $53.03 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil Assembly, Ignition; Ignition Coil

- Replaces: 12647553

- Product Specifications

- Other Name: Ignition Coil

- Replaced by: 12726023

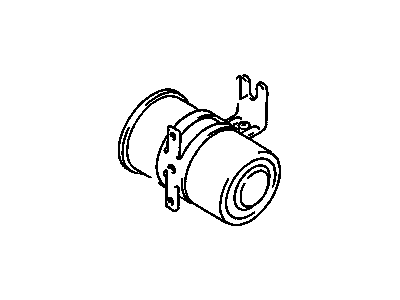

Chevrolet COIL ASM,IGN

Part Number: 19418996$70.67 MSRP: $145.86You Save: $75.19 (52%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Ignition Coil

- Replaces: 10489421, 19207138

Chevrolet COIL ASM,IGN

Part Number: 19418991$52.18 MSRP: $107.70You Save: $55.52 (52%)Ships in 1 Business DayProduct Specifications- Other Name: Coil, Coil Assembly, Ignition Coil

- Replaces: 10472401, 10482928, 19353734

Chevrolet COIL KIT,IGN

Part Number: 19418995$41.50 MSRP: $114.58You Save: $73.08 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil, Ignition Coil

- Replaces: 01115468, 12498334, 01115315, 1115315, 1115468

Chevrolet COIL ASM-IGN

Part Number: 12710620$39.09 MSRP: $70.78You Save: $31.69 (45%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Ignition Coil

- Replaces: 12698943

- Product Specifications

- Other Name: Ignition Coil

- Replaces: 12556450, 12558948

Chevrolet Ignition Coil Assembly

Part Number: 25182496$104.69 MSRP: $216.06You Save: $111.37 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil Asm,Ignition; Ignition Coil

- Replaces: 96253555

Chevrolet Ignition Coil Kit

Part Number: 12498336$73.53 MSRP: $151.76You Save: $78.23 (52%)Ships in 1 Business DayProduct Specifications- Other Name: Coil Kit,Ignition ; Coil, Ignition Coil; Coil, Ignition Coil

- Replaces: 01985474, 1985474

Chevrolet COIL ASM-IGN

Part Number: 28289935$115.34 MSRP: $217.62You Save: $102.28 (47%)Ships in 1-2 Business DaysProduct Specifications- Replaces: 25190788, 96983945

- Product Specifications

- Other Name: Ignition Coil

- Replaced by: 12723610

- Replaces: 12619161, 12669351

Chevrolet Coil Assembly, Ign

Part Number: 25203537$36.21 MSRP: $59.93You Save: $23.72 (40%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Ignition Coil

- Replaced by: 25205340

Chevrolet Coil Assembly, Ign

Part Number: 12707304$33.23 MSRP: $62.70You Save: $29.47 (47%)Ships in 1 Business DayProduct Specifications- Other Name: Ignition Coil

- Replaced by: 12741091

- Replaces: 12666339

- Product Specifications

- Other Name: Coil Asm,Ignition ; Coil, Ignition Coil; Ignition Coil

- Product Specifications

- Other Name: Coil Asm,Ignition (On Esn) ; Coil, Ignition Coil

- Replaces: 96066466

| Page 1 of 4 |Next >

1-20 of 73 Results

Chevrolet Ignition Coil

At GMPartsGiant.com, we offer an extensive inventory of genuine Chevrolet Ignition Coils at competitive prices in the market. All our OEM Chevrolet Ignition Coils are backed by the manufacturer's warranty and will be shipped promptly to your doorstep. Rest assured, our hassle-free return policy is designed to support you throughout your shopping experience!

Chevrolet Ignition Coil Parts Questions & Experts Answers

- Q: How to replace an ignition coil in a distributor on Chevrolet Astro?A:Detach the cable from the negative terminal of the battery. Remove the distributor cap and rotor. Remove the distributor from the engine. Detach the pick-up coil leads from the module. Connect one lead of an ohmmeter to the terminal of the pick-up coil lead and the other to ground as shown. Flex the leads by hand to check for intermittent opens. The ohmmeter should indicate infinite resistance at all times. If it doesn't, the pick-up coil is defective and must be replaced. Connect the ohmmeter leads to both terminals of the pick-up coil lead. Flex the leads by hand to check for intermittent opens. The ohmmeter should read one steady value between 500 and 1500 ohms as the leads are flexed by hand. If it doesn't, the pick-up coil is defective and must be replaced. Remove the spring from the distributor shaft. Mark the distributor tang drive and shaft so that they can be reassembled in the same position. If the distributor is equipped with a Hall Effect switch attached to the top of the pick-up coil, remove the two retaining screws. Carefully mount the distributor in a soft-jawed vise and, using a hammer and punch, remove the roll pin from the distributor shaft and gear. Remove the distributor shaft. Remove the driven gear and spacer washers from the end of the shaft, making sure to note the order in which you remove any spacers. Remove the shaft from the distributor. To remove the pick-up coil, remove the thin "C" washer (on four-cylinder models) or the retaining clip. Lift the pick-up coil assembly straight up and remove it from the distributor. Note the order in which you remove the pieces. Reassembly is the reverse of disassembly. Installation is the reverse of removal.

- Q: How to check and replace an ignition coil on Chevrolet Nova?A:To check pick up coil first you need to remove the distributor cap, then you have to remove the rotor and you have to disconnect the pick-up coil leads from the module. Short an ohmmeter between the pick-up connector or wire and ground by touching each terminal, one at a time, and take note of the reading; an ohmmeter reading for a good pick-up coil should be infinity; if it is anything less than the pick-up coil is bad. Fourth, switch the ohmmeter towards both terminals on the pick-up coil connector, vacuum to the vacuum advance unit if it exists, and therefore the ohmmeter should read steady a minimum of 500 accompanied with a maximum of 1500 ohms while bending the wires; a failure here also implies a faulty pick-up coil. If the pick-up coil does not pass either test it should be replaced. This is eliminated, and instead, remove the distributor and mark the shaft and gear for gear assembly again. Place the distributor shaft housing in a bench vise; push out the roll pin to removed the gear and tanged washer-, check if there are burr in the shaft before pulling up the shaft. Three of the screws need to be unscrewed to remove the magnetic shield, as well as it is necessary to insert a flat-head screw-driver under the c-clip and turn it and pull out to remove the pick-up coil assembly. Put in the new pick-up coil assembly and make sure that the C-clip is in place, replace the shaft, make sure is clean and greased. Next piece is the tanged washer, fit it in such a way that the tangs are facing up, then the gear and then the roll pin. Rotate the shaft so that the teeth of the distributor shaft do not make any contact with the pick-up coil pole piece; if they make contact then adjust the pole piece and tighten it. Finally, reinstall the distributor.

- Q: How to replace the Alternator and Ignition Coil on Chevrolet Metro?A:When replacing the pick-up coil in a vacuum/centrifugal advance distributor then go ahead and remove the distributor cap or the rotor and then the distributor. After that the module can be pulled off by simply removing the dust cover and unsoldering the red and white cables. Most of the screws securing the pick-up coil must be unscrewed to release the coil. Connect an ohmmeter between the red and white wires and the multi-meter should read a value within the stipulated limits and if this is not the case, the pick-up coil is bad. For installation, reverse the above mentioned removal procedures and make sure that the red and white leads are not crossed since they will cause damage. For the generator assembly at an electronic spark control distributor, one has to remove the lead of the generator assembly and place an ohmmeter measuring the range of resistance which should also be within the prescribed limit. If it is not the case, then the generator assembly has to be replaced by a new one. Remove the distributor cap, cap seal and the rotor in the first step, secondly, the dust cover and the three screws will have to be undone to get the generator assembly off. Reinstallation is done in the reverse order to the installation process, and in its completion it is recommended that the air gap be checked and if agreeable left alone or adjusted.

Related Chevrolet Parts

Browse by Model

Astro Ignition Coil Avalanche Ignition Coil Aveo Ignition Coil Beretta Ignition Coil Blazer Ignition Coil C10 Ignition Coil C1500 Ignition Coil C20 Ignition Coil C2500 Ignition Coil C30 Ignition Coil C3500 Ignition Coil Cadet Ignition Coil Camaro Ignition Coil Caprice Ignition Coil Captiva Sport Ignition Coil Cavalier Ignition Coil Celebrity Ignition Coil Chevette Ignition Coil Citation Ignition Coil City Express Ignition Coil Cobalt Ignition Coil Colorado Ignition Coil Corsica Ignition Coil Corvette Ignition Coil Cruze Ignition Coil El Camino Ignition Coil Equinox Ignition Coil Express Ignition Coil G10 Ignition Coil G20 Ignition Coil G30 Ignition Coil HHR Ignition Coil Impala Ignition Coil K10 Ignition Coil K1500 Ignition Coil K20 Ignition Coil K2500 Ignition Coil K30 Ignition Coil K3500 Ignition Coil Lumina Ignition Coil Malibu Ignition Coil Metro Ignition Coil Monte Carlo Ignition Coil Nova Ignition Coil Orlando Ignition Coil P20 Ignition Coil P30 Ignition Coil Prizm Ignition Coil R10 Ignition Coil R20 Ignition Coil R2500 Ignition Coil R30 Ignition Coil R3500 Ignition Coil S10 Ignition Coil SS Ignition Coil SSR Ignition Coil Silverado Ignition Coil Sonic Ignition Coil Spark Ignition Coil Spectrum Ignition Coil Sprint Ignition Coil Storm Ignition Coil Suburban Ignition Coil Tahoe Ignition Coil Tracker Ignition Coil Trailblazer Ignition Coil Traverse Ignition Coil Trax Ignition Coil Uplander Ignition Coil V10 Ignition Coil V20 Ignition Coil V30 Ignition Coil V3500 Ignition Coil Venture Ignition Coil Volt Ignition Coil