My Garage

My Account

Cart

Genuine Chevrolet K1500 Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

24 Cylinder Heads found

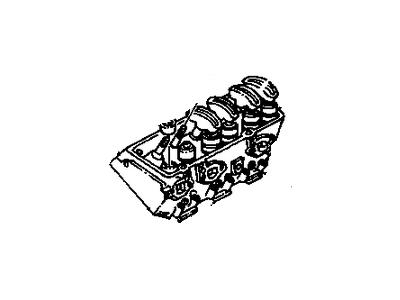

Chevrolet K1500 Cylinder Head Assembly (W/Studs)

Part Number: 12533558$310.73 MSRP: $491.12You Save: $180.39 (37%)Ships in 1-3 Business DaysChevrolet K1500 Head Assembly, Cyl (W/ Vlv)

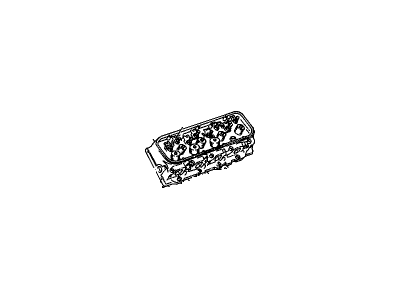

Part Number: 12691728$714.79 MSRP: $862.50You Save: $147.71 (18%)Ships in 1-3 Business DaysChevrolet K1500 Cylinder Head

Part Number: 12691725$761.93 MSRP: $1215.20You Save: $453.27 (38%)Ships in 1-3 Business DaysChevrolet K1500 Cylinder Head Assembly

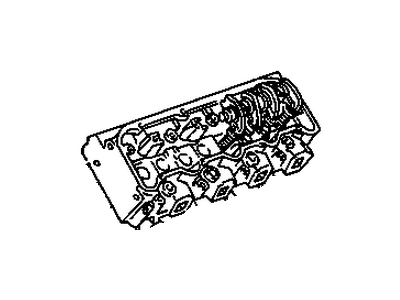

Part Number: 12523500$849.60 MSRP: $1130.09You Save: $280.49 (25%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 24 Results

Chevrolet K1500 Cylinder Head

As a central part of Chevrolet K1500 engines the Cylinder Head enables fuel and air flow to the engine after exhaust gases escape. The combustion chamber gets its upper section from the essential valves along with spark plugs which are housed in this component. Manufacturers of the K1500 employed cast iron and aluminum Cylinder Head in various series runs although they ultimately switched to aluminum because of its weight reduction benefits and enhanced power ratios together with better thermal management properties. Engine builders reinforce performance Cylinder Head in specific sections for improving airflow because enhanced airflow leads to greater horsepower output. Engine performance and leaks may occur due to worn guides and valves alongside gaskets since they represent common issues in Chevrolet Cylinder Head. Torque-to-yield head bolts work as a sealing system to achieve consistent clamping pressure for proper sealing. The performance output and operating efficiency of the Chevrolet K1500 engine heavily depend on the Cylinder Head function.

Each OEM Chevrolet K1500 Cylinder Head we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet K1500 Cylinder Head Parts Questions & Experts Answers

- Q: How to thoroughly clean cylinder heads and related valve train components on Chevrolet K1500?A:Clean the cylinder heads thoroughly and its related valve train components, removing old gasket material from the head gasket, along with sealing compound at the intake manifold and exhaust manifold sealing surfaces. Clear away scale buildup in the coolant passages and clean out via wire brush all kinds of holes as well as threaded holes. With a solvent wash down, completely dry cleaner rocker arm pivot stud threads, cylinder head, rocker arms push rods, spring retainers plus keepers, valve springs shields. The valves can be scraped to get rid of heavy deposits while the valve heads' epidermis can be cleaned free of deposit through electrically driven wire brushes. Examine for cracks in coolant wairs or warping. The condition of valves seating stem guide clearance faces spring wear retainers and covers end pivots are checked out for wear damage or proper installation by measuring margin width on spring seats as well as blade contact area between two adjacent rockers push rod ends bolted stud guide plates pull rods arm nuts studs are observed at every opportunity if broken replace them. For poor conditions reassemble valve parts into cylinder head: however for good conditions, reassemble them without major service operations performed on the same parts again.