My Garage

My Account

Cart

Genuine Chevrolet PCV Valve Hose

Positive Crankcase Ventilation Valve Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

298 PCV Valve Hoses found

- Product Specifications

- Other Name: TUBE, Engine Crankcase Ventilation; PCV Tube

- Replaces: 12662657, 12654851

Chevrolet Tube Assembly, Int Air Duct Pcv

Part Number: 12687313$12.10 MSRP: $24.68You Save: $12.58 (51%)Product Specifications- Other Name: PCV Tube

- Replaces: 12670880, 12670874

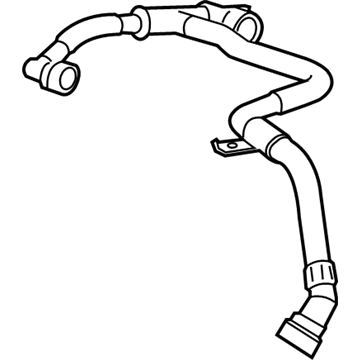

Chevrolet PVC Tube Assembly

Part Number: 12670979$50.46 MSRP: $102.92You Save: $52.46 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TUBE, Engine Crankcase Ventilation

- Replaces: 12663623

- Product Specifications

- Other Name: TUBE, Engine Crankcase Ventilation

Chevrolet Tube Assembly, Pcv (Rh Rocker To Oil Tnk)

Part Number: 12670978$58.48 MSRP: $119.30You Save: $60.82 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TUBE, Engine Crankcase Ventilation

- Replaces: 12641291, 12659195

- Product Specifications

- Other Name: TUBE, Engine Crankcase Ventilation

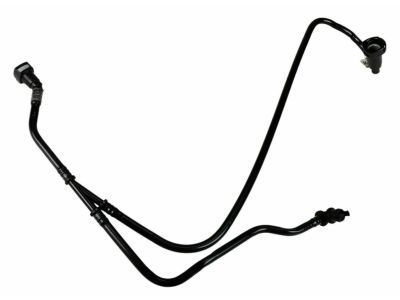

Chevrolet Tube Assembly, Pcv Foul Air

Part Number: 12703915$38.10 MSRP: $77.72You Save: $39.62 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: PCV Tube

- Replaces: 12701760, 12664809

Chevrolet PVC Tube Assembly

Part Number: 12670908$36.00 MSRP: $72.78You Save: $36.78 (51%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Tube Assembly, Pcv; PCV Tube

- Replaces: 12645127

Chevrolet Tube Assembly, Pcv (Lh Rocker To Air Induct)

Part Number: 12670910$46.08 MSRP: $94.00You Save: $47.92 (51%)Product Specifications- Other Name: Tube Assembly, Pcv (Lh Rkr To Air Induct); PCV Tube

- Replaces: 12631870, 12663620

Chevrolet Tube Assembly, Pcv

Part Number: 12631869$39.35 MSRP: $74.24You Save: $34.89 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TUBE, Engine Crankcase Ventilation; PCV Tube

- Product Specifications

- Other Name: TUBE, Engine Crankcase Ventilation

- Replaced by: 19435537

- Product Specifications

- Other Name: TUBE, Engine Crankcase Ventilation; PCV Valve

- Product Specifications

- Other Name: TUBE, Engine Crankcase Ventilation; Crankcase Tube

- Product Specifications

- Other Name: TUBE, Engine Crankcase Ventilation; PCV Valve

Chevrolet Tube Assembly, Pcv (Foul Air)

Part Number: 12638437$25.05 MSRP: $44.94You Save: $19.89 (45%)Product Specifications- Other Name: TUBE, Engine Crankcase Ventilation

- Replaces: 12609021

- Product Specifications

- Other Name: TUBE, Engine Crankcase Ventilation

- Product Specifications

- Other Name: Tube Assembly, Pcv; PCV Tube

- Replaces: 25201118, 12673869

Chevrolet Positive Crankcase Ventilation Tube

Part Number: 12687544$41.41 MSRP: $74.28You Save: $32.87 (45%)Product Specifications- Other Name: Tube Assembly PCV; PCV Tube

- Replaces: 12673970

- Product Specifications

- Other Name: Tube Assembly, Pcv

- Product Specifications

- Replaces: 12634309

| Page 1 of 15 |Next >

1-20 of 298 Results

Chevrolet PCV Valve Hose

At GMPartsGiant.com, we offer an extensive inventory of genuine Chevrolet PCV Valve Hoses at competitive prices in the market. All our OEM Chevrolet PCV Valve Hoses are backed by the manufacturer's warranty and will be shipped promptly to your doorstep. Rest assured, our hassle-free return policy is designed to support you throughout your shopping experience!

Chevrolet PCV Valve Hose Parts Questions & Experts Answers

- Q: How Should You Inspect and Maintain Hoses, Fuel Lines and PCV Valve Hose on Chevrolet Cruze?A:Temperature increases inside the hood can cause rubber and plastic hoses of engine, accessory and emission systems degrade and thus require regular checks for cracks, loose clamps, hardening of the material and leaks. Most hoses are fitted with clamps and these should be tightened so as to avoid leakage; if there are no clamps, one should check whether the hose has swollen or become rigid at the junction. The PCV system releases crankcase blow-by gas through a rubber hose to the intake manifold where it is combined with the air intake before combustion and thus the PCV hose should be checked for cracks and blockage, it should then be cleaned using a solvent if blocked. vacuum hoses may be of different colours and should be replaced when the wall thickness become too thin and the temperature resistance is low; it is better to remove hoses for check or for some closing it is better label it for installation further. Check plastic T-fittings for cracks and hose distortions which can cause leak and use a small piece of vacuum hose as it is a stethoscope to find vacuum leaks. Fuel lines, most of which are made from flexible hoses, should be inspected as to its deterioration particularly at the bends and fittings; only the proper hose for the particular application of fuel injection system should the old hose be replaced with. Typically, spring-type clamps on fuel return or vapour lines should be replaced with screw clamps and special tools may be required for spring lock couplings. Fuel lines contain metal lines and must be checked for bend, crimps, or cracks; the preference for replacement is seamless steel tubes, as copper and aluminum cannot handle the pressure. Further, the metal brake line must be checked for cracks or loosing of the fittings and any sort of leakage of the brake fluid indicates the need to inspect the brake system.

Related Chevrolet Parts

Browse by Model

Astro PCV Valve Hose Avalanche PCV Valve Hose Aveo PCV Valve Hose Beretta PCV Valve Hose Blazer PCV Valve Hose C10 PCV Valve Hose C1500 PCV Valve Hose C20 PCV Valve Hose C2500 PCV Valve Hose C30 PCV Valve Hose C3500 PCV Valve Hose Cadet PCV Valve Hose Camaro PCV Valve Hose Caprice PCV Valve Hose Captiva Sport PCV Valve Hose Cavalier PCV Valve Hose Celebrity PCV Valve Hose Citation PCV Valve Hose City Express PCV Valve Hose Cobalt PCV Valve Hose Colorado PCV Valve Hose Corsica PCV Valve Hose Corvette PCV Valve Hose Cruze PCV Valve Hose El Camino PCV Valve Hose Equinox PCV Valve Hose Express PCV Valve Hose G10 PCV Valve Hose G20 PCV Valve Hose G30 PCV Valve Hose HHR PCV Valve Hose Impala PCV Valve Hose K10 PCV Valve Hose K1500 PCV Valve Hose K20 PCV Valve Hose K2500 PCV Valve Hose K30 PCV Valve Hose K3500 PCV Valve Hose Lumina PCV Valve Hose Malibu PCV Valve Hose Metro PCV Valve Hose Monte Carlo PCV Valve Hose P20 PCV Valve Hose P30 PCV Valve Hose Prizm PCV Valve Hose R10 PCV Valve Hose R20 PCV Valve Hose R2500 PCV Valve Hose R30 PCV Valve Hose R3500 PCV Valve Hose S10 PCV Valve Hose SS PCV Valve Hose SSR PCV Valve Hose Silverado PCV Valve Hose Sonic PCV Valve Hose Spark PCV Valve Hose Sprint PCV Valve Hose Storm PCV Valve Hose Suburban PCV Valve Hose Tahoe PCV Valve Hose Tracker PCV Valve Hose Trailblazer PCV Valve Hose Traverse PCV Valve Hose Trax PCV Valve Hose Uplander PCV Valve Hose V10 PCV Valve Hose V20 PCV Valve Hose V30 PCV Valve Hose V3500 PCV Valve Hose Venture PCV Valve Hose Volt PCV Valve Hose