My Garage

My Account

Cart

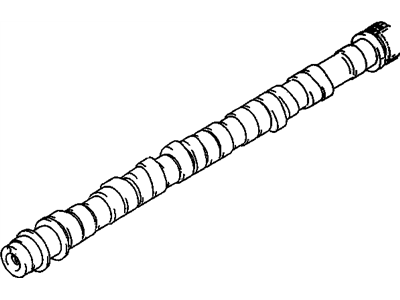

Genuine Chevrolet Tracker Camshaft

Cam- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Camshafts found

Chevrolet Tracker Camshaft

Camshaft on the Chevrolet Tracker helps it to control the intake and exhaust valves directing airflow into the cylinder matter for combustion. OHV is used in some motorcycle engines, some motorcycle engines have SOHC, and others have DOHC to provide more varieties for the desired engine performance. With the help of such parameters as lift, duration or separation angle of the lobe, camshaft can control the power and RPM. There are superior performance camshafts that can be installed to improve engine capacity with regard to the desired level of performance and other alterations. All in all, the camshaft is the essential part, responsible for directly delivering the overall output and effectiveness of a Chevrolet Tracker vehicle.

Each OEM Chevrolet Tracker Camshaft we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Tracker Camshaft Parts Questions & Experts Answers

- Q: How to clean and inspect Camshaft and Cylinder Head on Chevrolet Tracker?A:When performing an engine overhaul, it is necessary to meticulously clean and thoroughly inspect the cylinder head(s) and related valve train components so as to effectively evaluate their condition. It is always important that you look out for any signs of cylinder head warpage especially if the engine has suffered severe overheating. Cleaning involves carefully scraping off old gasket material from surfaces of the head gasket, intake manifold, and exhaust manifold without damaging the cylinder head. Specialized gasket removal solvents might be used and accumulated scale in coolant passages should be cleared. Use a stiff wire brush to remove deposits from holes and clean up threaded holes with an appropriate size tap; while using compressed air to blow away debris. Remove oil from rocker arm shaft holes and then clean up the cylinder head and components with solvent, hastening the drying process by blowing them out with compressed air. Caustic decarbonizing chemicals may be used but handle them carefully. As regards inspection, check for cracks in the cylinder head, coolant leakage or damage; consult an automotive machine shop in case of cracks. Inspect for warpage on the head gasket mating surface using a straight edge and feeler gauge according to specified limits. Examine valve seats in combustion chambers for pitting, cracks or burning. Using a dial indicator measure valve stem-to-guide clearance; ask a machine shop for help on this subject if needed. Check valve faces for wear, distortion, cracks etc; ensure that valve stems, necks are well within standards as well as overall conditions of valves. Measure valve margin width then replace valves with narrow margins. Inspect spring retainers, keepers and rocker arm components in order to ascertain their durability; hence replace parts whose viability is questionable. In SOHC engines assess rocker arm faces, pivot contact areas, shafts and adjusters for damage including wear as well as squareness. Valves could then be reassembled into the cylinder heads if these components are in bad shape or excessively worn. Examine camshaft journals, rocker arms and lobes for damage including wear through signs of overheating. Measure cam lobe height, journal diameter and housing bore to assess wear and roundness. In DOHC engines, lifter contact with sliding surfaces must be looked at for wear, damage and scratches; also ensure that it moves in its bore. Measure lifter and lifter bore diameters in order to determine clearance then replace components or cylinder head when necessary.