My Garage

My Account

Cart

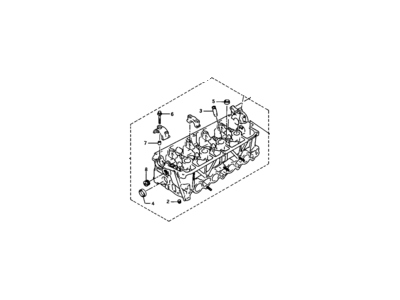

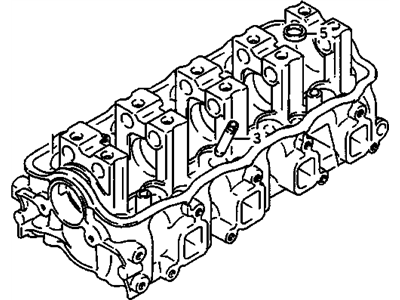

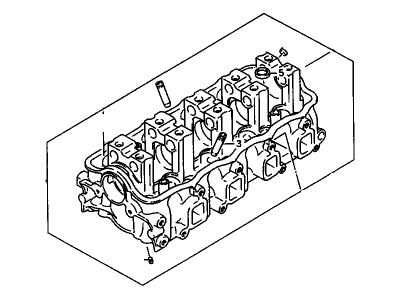

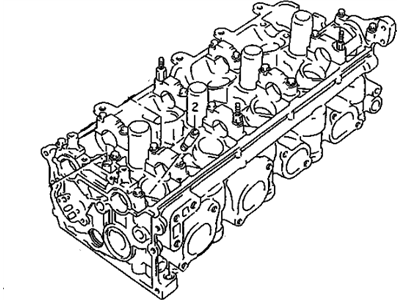

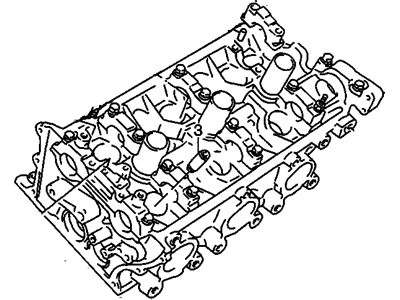

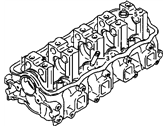

Genuine Chevrolet Tracker Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Cylinder Heads found

Chevrolet Tracker Cylinder Head

Each OEM Chevrolet Tracker Cylinder Head we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Chevrolet Tracker Cylinder Head Parts Questions & Experts Answers

- Q: How to remove and reinstall a cylinder head on SOHC engine on Chevrolet Tracker?A:Allow the engine to cool completely before following this procedure. Position the number one piston at Top Dead Center. Disconnect the negative cable from the battery. Drain the cooling system and remove the spark plugs. Remove the intake manifold. Remove the Exhaust Manifold. Remove the distributor, including the cap and wires. On carbureted models, remove the fuel pump. Remove the Timing Belt. Remove the camshaft cover. On 16-valve engines, also remove the camshaft and intake Rocker Arms. Using a 14 mm socket, loosen the cylinder head bolts, 1/4-turn at a time, in the reverse of the sequence shown until they can be removed by hand. Carefully lift the cylinder head straight up and place the head on wooden blocks to prevent damage to the sealing surfaces. If the head sticks to the engine block, dislodge it by prying against a protrusion on the head casting. Note: Cylinder head disassembly and inspection procedures are covered in Part B. It's a good idea to inspect the camshaft and have the head checked for war page, even if you're just replacing the gasket. Remove all traces of old gasket material from the block and head. Do not allow anything to fall into the engine. Clean and inspect all threaded fasteners and be sure the threaded holes in the block are clean and dry. Place a new gasket and the cylinder head in position. The cylinder head bolts should be tightened in several stages following the proper sequence to the torque. Reinstall the timing belt. Reinstall the remaining parts in the reverse order of removal. Be sure to refill the cooling system and check all fluid levels. Rotate the crankshaft clockwise slowly by hand through two complete revolutions. Recheck the camshaft timing marks. Start the engine and set the ignition timing. Run the engine until normal operating temperature is reached. Check for leaks and proper operation. Shut off the engine, remove the camshaft cover and retorque the cylinder head bolts, unless the gasket manufacturer states otherwise. Recheck the valve adjustment.

Related Chevrolet Tracker Parts

Browse by Year

2004 Cylinder Head 2003 Cylinder Head 2002 Cylinder Head 2001 Cylinder Head 2000 Cylinder Head 1999 Cylinder Head 1998 Cylinder Head 1997 Cylinder Head 1996 Cylinder Head 1995 Cylinder Head 1994 Cylinder Head 1993 Cylinder Head 1992 Cylinder Head 1991 Cylinder Head 1990 Cylinder Head 1989 Cylinder Head