My Garage

My Account

Cart

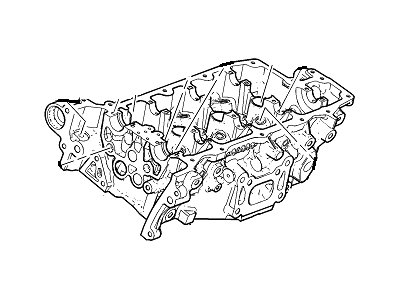

Genuine GMC Terrain Cylinder Head

Head- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Cylinder Heads found

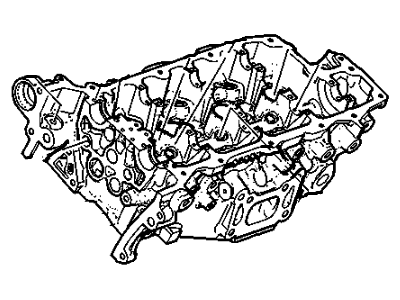

GMC Terrain Cylinder Head Assembly With Valve

Part Number: 12679101$718.11 MSRP: $1185.92You Save: $467.81 (40%)Ships in 1-3 Business DaysGMC Terrain Cylinder Head Assembly (Machining)

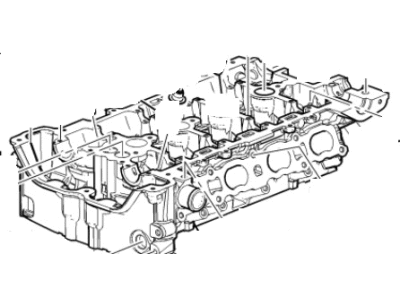

Part Number: 12608280$702.44 MSRP: $1428.81You Save: $726.37 (51%)Ships in 1-3 Business DaysGMC Terrain Cylinder Head Assembly With Valve

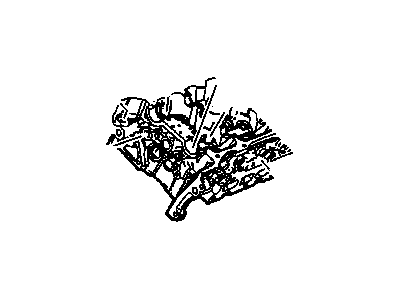

Part Number: 55504792$596.76 MSRP: $987.68You Save: $390.92 (40%)Ships in 1-3 Business DaysGMC Terrain Cylinder Head Assembly With Valve

Part Number: 12668716$408.87 MSRP: $676.72You Save: $267.85 (40%)Ships in 1-3 Business DaysGMC Terrain Head Assembly, Cyl (W/ Vlv)

Part Number: 12690428$1076.04 MSRP: $1713.67You Save: $637.63 (38%)Ships in 1-3 Business DaysGMC Terrain Cylinder Head Assembly (W/ Valve) (Rh)

Part Number: 12686767$856.78 MSRP: $1366.17You Save: $509.39 (38%)Ships in 1-3 Business DaysGMC Terrain Engine Cylinder Head (W/Vlvs)

Part Number: 12635548$299.00 MSRP: $474.37You Save: $175.37 (37%)Ships in 1-3 Business DaysGMC Terrain Cylinder Head Assembly With Valve

Part Number: 12692322$1093.89 MSRP: $1810.08You Save: $716.19 (40%)Ships in 1-3 Business DaysGMC Terrain Engine Cylinder Head (Machining)

Part Number: 12611606$878.50 MSRP: $1401.13You Save: $522.63 (38%)Ships in 1-3 Business DaysGMC Terrain HEAD ASM-CYL (W/ VLV)

Part Number: 12708953$563.37 MSRP: $898.51You Save: $335.14 (38%)Ships in 1-3 Business DaysGMC Terrain Engine Cylinder Head (W/Vlvs)

Part Number: 12641100$878.50 MSRP: $1401.13You Save: $522.63 (38%)GMC Terrain Cylinder Head Assembly With Valve

Part Number: 55501671$490.30 MSRP: $778.44You Save: $288.14 (38%)GMC Terrain HEAD ASM,CYL (REMAN)

Part Number: 19419467$1090.09 MSRP: $1728.22You Save: $638.13 (37%)

GMC Terrain Cylinder Head

Each OEM GMC Terrain Cylinder Head we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

GMC Terrain Cylinder Head Parts Questions & Experts Answers

- Q: How to remove and install cylinder heads in 3.4L V6 engine on GMC Terrain?A:Before taking off the cylinder heads, unbend the cable from the negative terminal of the battery, lift the vehicle on safety jack stands but first drain the cooling system and engine oil. Relieve the exhaust pressure by removing the exhaust pipe or pipes from the manifold or manifolds and lower the car. Playing it part by part, start by doffing the rocker arms and pushrods, the lower Intake Manifold, and the exhaust manifold. Should one remove the front head, then the dipstick tube must also be pulled out by the removing bolt on the front cylinder head. The removal of the rear cylinder head involves the removal of the heater outlet hose as well as the heater core outlet hose attached to the heater outlet tube; thereafter you have to remove the tube by naked force by the mere use of a nut. Take out the engine coolant temperature sensor, and the engine hoist bracket. Make sure all those elements that keep interfering with the cylinder head are removed, then follow by the removal of the spark plug. When it is time to remove the cylinder heads, undo each cylinder head bolt a quarter of a turn in the reverse order of the sequence that was used in the tightening process until they can be fully undone by hand: discard the bolts because new ones are needed for reassembly. Pull the head(s) up and away from the engine gently, ensuring therefore to look for nuts/bolts that one might have missed, and may use sledge hammer and bar of wood in breaking the gasket so that one can pull the head(s) off. Upon, removal position the head on wooden blocks to protect the gasket surfaces. For installation, it is required for the two surfaces of each cylinder head and block to be free from contaminants; use of a gasket scraper to remove gasket debris accompanied by brake system cleaner. The lifter valley should be covered with shop rags to prevent any debris from getting in and all areas where block and head interface should be inspected, and any damage repaired. Wash the threads in the head bolt holes with a tap Then put the new gasket on over the dowel pins on the block make certain that the gap is on the right side up. Safely position the head on the block over the existing gasket, new cylinder head bolts should be inserted and tightened according to sequence in the recommended torque then each bolt should be turned to the prescribed angle. Reverse the process of removal and charge the cooling system, while on the same process change the engine oil and filter.