My Garage

My Account

Cart

Genuine Oldsmobile Cutlass Shock Absorber

Suspension Shock Absorber- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

17 Shock Absorbers found

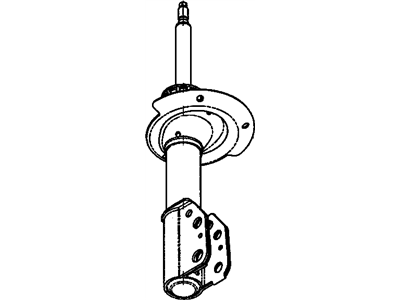

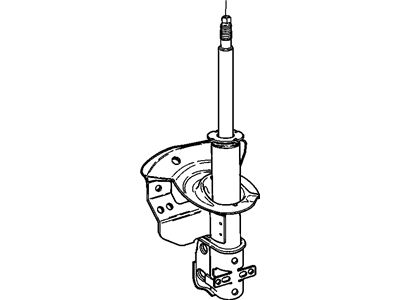

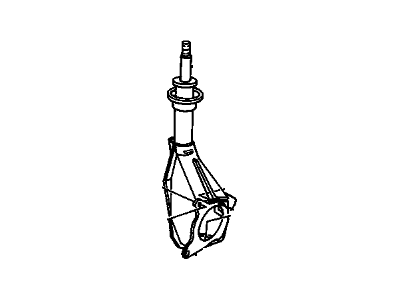

Oldsmobile Cutlass Front Suspension Strut Kit

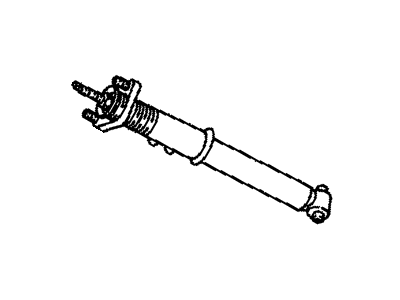

Part Number: 19180218$62.20 MSRP: $184.90You Save: $122.70 (67%)Ships in 1-2 Business DaysOldsmobile Cutlass Rear Shock Absorber Assembly

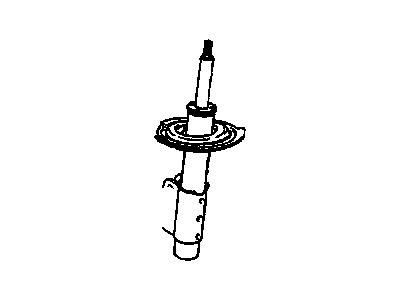

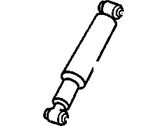

Part Number: 88945187$32.86 MSRP: $58.95You Save: $26.09 (45%)Ships in 1-2 Business DaysOldsmobile Cutlass Front Shock Absorber Assembly

Part Number: 88945324$56.88 MSRP: $102.02You Save: $45.14 (45%)

Oldsmobile Cutlass Shock Absorber

It is called the Shock Absorber and is used in Oldsmobile Cutlass vehicles which forms part of the suspension system aimed at preventing the car from bouncing too much and making the ride comfortable. Through mechanical or hydraulic systems, kinetic energy is dissipated as heat through the Shock Absorber reducing shock impulses accepted by the vehicle, making it easier to ride over irregular terrains. There are histories of the operation of the variety of Shock Absorbers that have been used in Oldsmobile Cutlass models which included the twin-tube and mono-tube. Twin-tube shocks are usual, they have little more complex design than monotube shocks and can be gas charged for greater longevity. As for the difference, mono-tube shocks are superior to twin-tube shocks in heat dissipation and performance, which also require multi-axial installation. Additional features such as Position Sensitive Damping (PSD) as well as Acceleration Sensitive Damping (ASD) enhances the levels of flexibility in handling situations further demonstrating the progress of Oldsmobile Cutlass Shock Absorber.

Each OEM Oldsmobile Cutlass Shock Absorber we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Oldsmobile Cutlass Shock Absorber Parts Questions & Experts Answers

- Q: What are the signs of shock absorber failure and how do you replace them on Oldsmobile Cutlass?A:Any sign of oil on the outside of shock absorber bodies indicates that the seals have started to leak, necessitating replacement of the units as assemblies. Internal failure of the shock absorber is more challenging to detect, although rear axle patter or tramp, especially on uneven road surfaces, may provide a clue. When a shock absorber is suspected to have failed, it should be removed from the vehicle and held in a vertical position while operating it for the full length of its stroke eight or ten times; any lack of resistance in either direction signals the need for replacement. For front shock absorber replacement, raise the front end of the vehicle, use an open-ended wrench to prevent the upper end from turning, and remove the upper stem retaining nut, retainer, and rubber grommet. Next, remove the two bolts retaining the lower shock absorber pivot to the Control Arm and pull the assembly out from the bottom. When installing, fit the lower retainer and rubber grommet over the upper stem, then install the shock absorber in the fully extended position through the lower control arm and spring. After the upper rubber grommet, retainer, and attaching nut are fitted, hold the upper stem with an open-ended wrench and torque-tighten the retaining nut. Install the bolts at the shock absorber lower pivot and torque tighten before lowering the vehicle. For rear shock absorber replacement, raise the rear end of the vehicle and support the rear axle. Remove the lower shock absorber retaining nut, retainer, and rubber grommet, followed by the two upper attaching bolts to remove the shock absorber. During installation, push the lower retainer and rubber grommet into position, extend the shock absorber to the proper length, and place it into position before installing the two upper attaching bolts. Finally, push the remaining retainer and grommet into position and install the lower attaching nut, torque all fasteners, and lower the vehicle.

Related Oldsmobile Cutlass Parts

Browse by Year

1999 Shock Absorber 1998 Shock Absorber 1997 Shock Absorber 1996 Shock Absorber 1995 Shock Absorber 1994 Shock Absorber 1993 Shock Absorber 1992 Shock Absorber 1991 Shock Absorber 1990 Shock Absorber 1989 Shock Absorber 1988 Shock Absorber 1987 Shock Absorber 1986 Shock Absorber 1985 Shock Absorber 1984 Shock Absorber 1983 Shock Absorber 1982 Shock Absorber