My Garage

My Account

Cart

Genuine Oldsmobile Transmission Assembly

Trans Assembly- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

122 Transmission Assemblies found

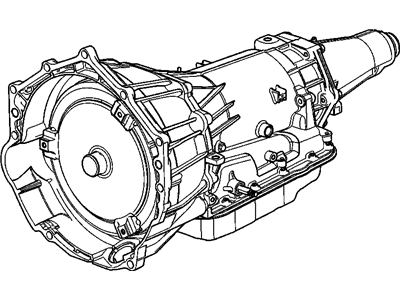

Oldsmobile Transmission, Auto (Goodwrench Remanufacture) (4Tdd)

Part Number: 12491883$2808.38 MSRP: $3160.28You Save: $351.90 (12%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Transmission, Manual(6, Speed); Transmission

- Replaces: 24227562

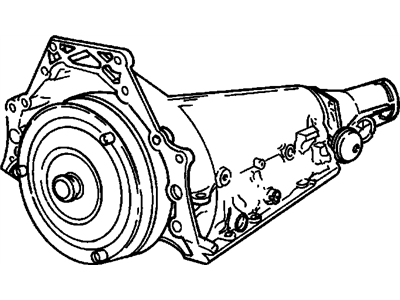

Oldsmobile Transmission Asm,Auto 4Sdd (Goodwrench Remanufacture)

Part Number: 12491882$2967.26 MSRP: $3340.00You Save: $372.74 (12%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Transmission, Manual(6, Speed)

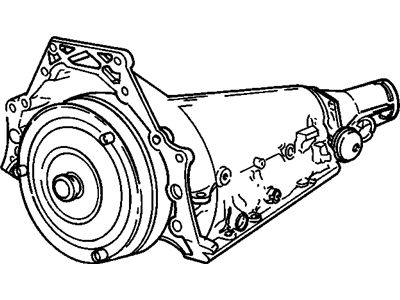

Oldsmobile Transmission, Auto (Goodwrench Remanufacture) (2Tdd)

Part Number: 24225949$2822.67 MSRP: $3176.44You Save: $353.77 (12%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Transmission, Manual(6, Speed); Transmission

- Replaces: 24221273

Oldsmobile Transmission, Auto (Goodwrench Remanufacture) (3Tdd)

Part Number: 24229164$2823.19 MSRP: $3177.03You Save: $353.84 (12%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Transmission, Manual(6, Speed); Transmission

- Replaces: 24224228

Oldsmobile Transaxle Asm, Auto (Goodwrench Remanufacture) (98Dcn)

Part Number: 19178258$487.49 MSRP: $2836.88You Save: $2349.39 (83%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TRANSAXLE, Automatic

- Replaces: 24213657, 24208802

Oldsmobile Transmission Asm,Auto (2Sdd) (Goodwrench Remanufacture)

Part Number: 24225948$2749.58 MSRP: $3093.75You Save: $344.17 (12%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Transmission, Manual(6, Speed); Transmission

- Replaces: 24221272

Oldsmobile Transmission Asm,Auto (3Sdd) (Goodwrench Remanufacture)

Part Number: 24229163$2994.89 MSRP: $3371.25You Save: $376.36 (12%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Transmission, Manual(6, Speed); Transmission

- Replaces: 24224227

Oldsmobile Transaxle Assembly, Man (3.94 Ratio)

Part Number: 12571728$1047.49Ships in 1-2 Business DaysProduct Specifications- Other Name: TRANSAXLE, Manual(5 Speed)

Oldsmobile Transaxle Asm, Auto (Goodwrench Remanufacture) (03Msn)

Part Number: 19178288$482.72 MSRP: $2993.13You Save: $2510.41 (84%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TRANSAXLE, Automatic

- Replaces: 24224456

Oldsmobile Transaxle Asm, Auto (Goodwrench Remanufacture) (98Dfn)

Part Number: 19178259$497.00 MSRP: $2836.88You Save: $2339.88 (83%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TRANSAXLE, Automatic; Transaxle

- Replaces: 24208803, 24213658

Oldsmobile Transaxle Asm,Auto (Goodwrench Remanufacture) 00Ycb

Part Number: 89059852$412.21 MSRP: $2320.50You Save: $1908.29 (83%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TRANSAXLE, Automatic; Transaxle

- Replaces: 24213651, 24215093, 89059848

Oldsmobile Transaxle Asm,Auto (Goodwrench Remanufacture) 00Ymb

Part Number: 89059853$412.57 MSRP: $2320.50You Save: $1907.93 (83%)Ships in 1-2 Business DaysProduct Specifications- Other Name: TRANSAXLE, Automatic; Transaxle

- Replaces: 24215094

Oldsmobile Transaxle Asm, Auto (Goodwrench Remanufacture) (96Pbw)

Part Number: 19178459$1891.38 MSRP: $2131.25You Save: $239.87 (12%)Ships in 1-3 Business DaysProduct Specifications- Other Name: TRANSAXLE, Automatic; Transaxle

- Replaces: 19125043

Oldsmobile Transmission Asm, Auto (4Shd) (Re manufactured)

Part Number: 8688976$2254.56 MSRP: $2542.09You Save: $287.53 (12%)Ships in 1-3 Business DaysProduct Specifications- Other Name: TRANSMISSION, Automatic

Oldsmobile Transmission Asm, Auto (4Tbd) (Re manufactured)

Part Number: 8688978$2254.56 MSRP: $2542.09You Save: $287.53 (12%)Ships in 1-3 Business DaysProduct Specifications- Other Name: TRANSMISSION, Automatic

Oldsmobile Automatic Transmission Assembly (Remanufactured)

Part Number: 8689978$2254.56 MSRP: $2542.09You Save: $287.53 (12%)Ships in 1-3 Business DaysProduct Specifications- Other Name: TRANSMISSION, Manual(5 Speed)

Oldsmobile Automatic Transmission Assembly (Remanufactured)

Part Number: 8689977$2316.69 MSRP: $2612.38You Save: $295.69 (12%)Ships in 1-3 Business DaysProduct Specifications- Other Name: TRANSMISSION, Manual(5 Speed)

Oldsmobile Transmission, Auto(Goodwrench Remanufacture)

Part Number: 24216088$2371.94 MSRP: $2674.88You Save: $302.94 (12%)Product Specifications- Other Name: TRANSMISSION, Automatic; Transmission

- Replaces: 24212611

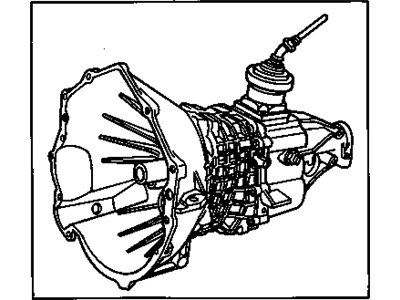

Oldsmobile Transmission Assembly, Man (Nv3500)

Part Number: 15067323$733.85 MSRP: $737.91You Save: $4.06 (1%)Product Specifications- Other Name: TRANSMISSION, Automatic; Transmission

- Replaces: 15769697

- Product Specifications

- Other Name: TRANSAXLE, Automatic; Transaxle

- Replaces: 24222040, 24218758, 24217322, 24228963

| Page 1 of 7 |Next >

1-20 of 122 Results

Oldsmobile Transmission Assembly

Looking to acquire brand new parts? Consider exploring our extensive inventory of genuine Oldsmobile Transmission Assemblies. Our offering of OEM Oldsmobile Transmission Assemblies not only comes with competitive prices but also includes a manufacturer's warranty. For added convenience, we provide a hassle-free return policy and rapid delivery service. Shop with confidence on our platform.

Oldsmobile Transmission Assembly Parts Questions & Experts Answers

- Q: How to remove a manual or automatic Transmission Assembly in V8 engine on Oldsmobile Cutlass?A:To do this remove all the screws and the cover plate from the lower front face of the clutch bell housing, then the bolts holding the bell housing to the engine. Bear the weight of the transaxle and pull it back perpendicular to prevent damaging the clutch disc while this main drive gear is engaged to its splined hub. Slowly turn each clutch cover bolt anticlockwise until all the springs pressure is released and then slowly take out the assembly out from the face of the flywheel, make sure the disc does not fall off. Connecting the transmission back to the engine can be done in reverse to putting on the clutch disc cover with the disc centered if it was removed. To start with, unless working on an automatic transmission, there is a cover plate on the lower front face of the converter housing which has to be removed after which loosening of the driveplate to torque converter bolts using the crankshaft in cases where they are not easily accessed. Locate the relative position of the driveplate to the torque converter, then immobilise the driveplate using a large screwdriver to jam the starter ring gear. Sustain the transmission on blocks and unbolt the converter bellhousing to engine bolts and then you can pull out the engine away from the torque converter, with the hoist or a floor jack, and to maintain the torque converter pressed at the rear, until it is fully locked within the oil pump. Reconnection involves the undoing of the above mentioned steps, ensuring that the torque converter and driveplate have their mating marks lined correctly and tightening of the bolts to the required torque.