My Garage

My Account

Cart

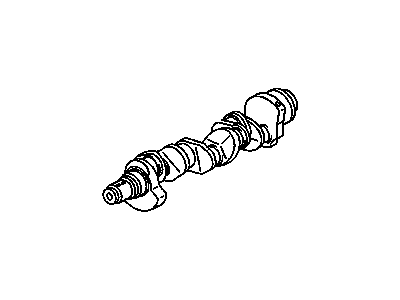

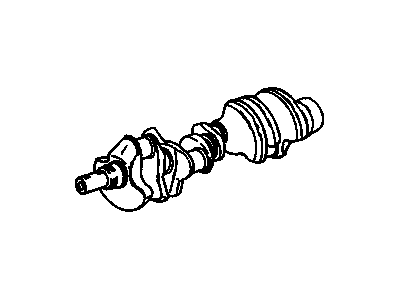

Genuine Pontiac Fiero Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Crankshafts found

Pontiac Fiero Crankshaft

Each OEM Pontiac Fiero Crankshaft we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Fiero Crankshaft Parts Questions & Experts Answers

- Q: How should the crankshaft be cleaned and inspected for damage on Pontiac Fiero?A:Wash the crankshaft with solvent and allow the same to dry completely, while cleaning this part, clean the oil holes with a stiff brush while washing with solvent. One should examine the main and the connecting rod bearing journals for signs of wear in that, and or-appearing as uneven wear, scoring, pitting, and cracks; a crankshaft in the same way should be checked for signs of cracks or damages. From the main and connecting rod journal using micrometer take measurements at several points to detect taper and out of round condition of journals and compare the same with the specified main and rod journal diameters. Use a master feeler gauge to measure the thickness of the journal at different circumferences, and thereby check if the journal is out-of-round; meantime, use micrometers to check if the two ends of the journal, close to the crank counterweights, are tapering. If the crankshaft journals are damaged or tapered, out-of-round or worn beyond specified limits, the crankshaft may be reground by an automotive machine shop and if reconditioning is necessary, undersize bearing inserts must be used.