My Garage

My Account

Cart

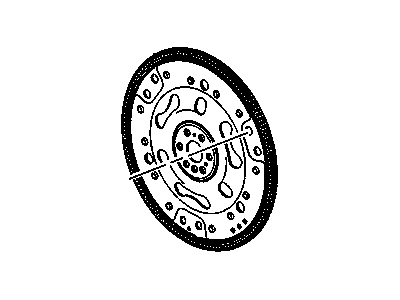

Genuine Pontiac Fiero Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Flywheels found

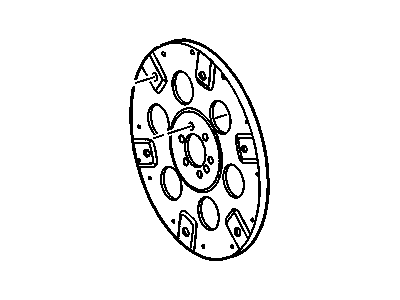

Pontiac Fiero Engine Crankshaft Flywheel

Part Number: 10118669$287.17 MSRP: $428.19You Save: $141.02 (33%)Ships in 1-2 Business Days

Pontiac Fiero Flywheel

The Pontiac Fiero Flywheel fulfills three main duties by maintaining rotational energy for power output smoothing and by joining the starter drive to crankshaft rotation when the ignition begins and by delivering friction contact to the clutch wheel. There exist two main types of Flywheels including solid Flywheels and dual mass Flywheels (DMFs). The solid Flywheel maintains simple functionality whereas DMF combines two components through a damping unit that both improves vehicle performance and minimizes engine noise. The many frequent cause of Flywheel substitution is the surface deterioration found on its clutch connection section. Inner failure of DMFs together with damage to their ring gears leads to replacement needs. The replacement of new system parts stands as the preferred method since resurfacing procedures are not suitable for dual mass replacement units (DMFs). A smooth running engine with efficient clutch operation depends on the Pontiac Fiero replacement part in the Pontiac Fiero.

Each OEM Pontiac Fiero Flywheel we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Fiero Flywheel Parts Questions & Experts Answers

- Q: How to remove and install the flywheel on Pontiac Fiero?A:Because a special engine support beam, a telescoping transaxle stand, a hydraulic hoist, and an engine hoist are needed to remove the transaxle, gaining access to the flywheel using the procedure may be impossible for most home mechanics. An alternative involves the removal of the engine, transaxle, and cradle as an assembly, which does not require the special engine support beam or the telescoping transaxle stand, although the hydraulic hoist and engine hoist must still be available. Once the engine/transaxle/cradle assembly is removed from the vehicle, the transaxle can be disconnected from the engine to gain access to the flywheel. Begin by removing the transaxle assembly from the engine, followed by the pressure plate and clutch disc, and then remove the flywheel mounting bolts to detach the flywheel assembly. For installation, first install the flywheel and bolts, tightening them to the specified torque in a criss-cross pattern, then install the pressure plate and clutch disc, and finally attach the transaxle assembly to the engine.