My Garage

My Account

Cart

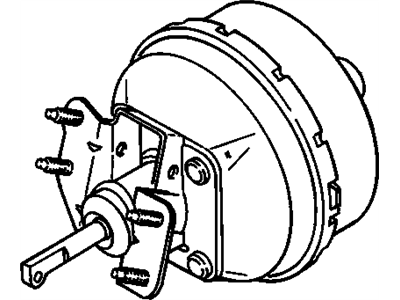

Genuine Pontiac Firebird Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

3 Brake Boosters found

Pontiac Firebird Brake Booster

The brake booster in Pontiac Firebird automobiles remains crucial in improving the braking system since it lessens pressure from the driver whenever he/she applies the brake pedal. It mainly works by vacuum action, the pressure being developed by the engine vacuum and by the atmospheric pressure and in proportion to the pressure applied on the brake pedal to the master cylinder. Many Pontiac Firebird cars have come with both the vacuum operated as well as hydraulic brake boosters. Vacuum boosters are quite effective but sometimes may fail while hydraulic boosters make use of the pressure that is created by the power steering pump or an electrical assembly. It is recommended to put the performance brake boosters and the conversion kits in restorers of the classic Firebirds, they come in different sizes and diaphragmatic designs depending on the need of the car. There are generally single diaphragm boosters and dual diaphragm boosters: the difference between them can provide radically different levels of assistance in custom built cars.

Each OEM Pontiac Firebird Brake Booster we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Firebird Brake Booster Parts Questions & Experts Answers

- Q: How to Remove and Install the Brake Booster on Pontiac Firebird?A:The power brake unit has no regular servicing but to check the condition of the hoses and the air filter just below the boot of the push rod end. It is necessary to use special tools and skills for the dismantling of the unit and in the event of a defect, it is better to fit a new or factory exchange unit than to attempt to repair a particular booster original. Start by loosening the mounting nuts that hold the master cylinder to the power brake then move the master cylinder aside without stressing the hydraulic lines. If the possible flexibility of the lines is in doubt disconnect at the cylinder and cap the openings. Subsequently, pull the vacuum hose connected to the front of the power brake booster and then plug the ending of the hose. Half turn at least the four nuts fixing the booster to the firewall but do not take them off at this point. In the car, release the clip and withdraw the power brake pushrod from the Brake Pedal but do not force it laterally. After that, turn the four booster mounting nuts and then gently pull the unit from the engine compartment. For assembly, the four mounting nuts should be loosely installed and the pushrod connected to the brake pedal and then the nuts tightened to the required torque again reconnecting the vacuum hose and the master cylinder. If hydraulic Brake Lines were disconnected, the entire brake system should be flushed to remove any air which may have entered it.

Related Pontiac Firebird Parts

Browse by Year

2002 Brake Booster 2001 Brake Booster 2000 Brake Booster 1999 Brake Booster 1998 Brake Booster 1997 Brake Booster 1996 Brake Booster 1995 Brake Booster 1994 Brake Booster 1993 Brake Booster 1992 Brake Booster 1991 Brake Booster 1990 Brake Booster 1989 Brake Booster 1988 Brake Booster 1987 Brake Booster 1986 Brake Booster 1985 Brake Booster 1984 Brake Booster 1983 Brake Booster 1982 Brake Booster