My Garage

My Account

Cart

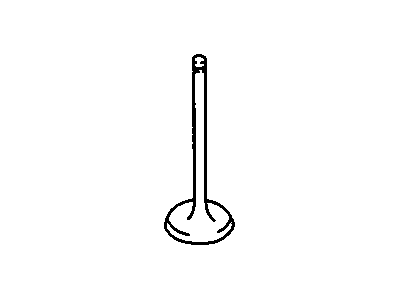

Genuine Pontiac Firebird Intake Valve

Engine Intake Valve- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

27 Intake Valves found

Pontiac Firebird Intake Valve

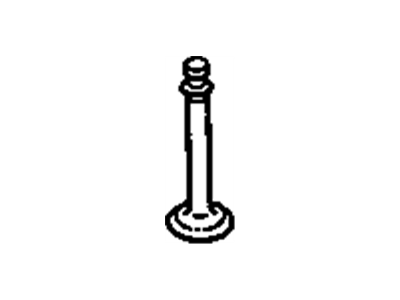

Part Number: 12563063$24.89 MSRP: $41.20You Save: $16.31 (40%)Ships in 1-2 Business DaysPontiac Firebird Intake Valve

Part Number: 10241743$19.57 MSRP: $32.40You Save: $12.83 (40%)Ships in 1-2 Business DaysPontiac Firebird Valve, Inlet

Part Number: 25512098$13.15 MSRP: $26.53You Save: $13.38 (51%)Ships in 1-2 Business DaysPontiac Firebird Valve, Inlet

Part Number: 12550457$17.85 MSRP: $20.54You Save: $2.69 (14%)Ships in 1-2 Business DaysPontiac Firebird Intake Valve

Part Number: 10168465$6.53 MSRP: $40.09You Save: $33.56 (84%)Ships in 1-2 Business DaysPontiac Firebird Intake Valve

Part Number: 10045252$6.83 MSRP: $19.40You Save: $12.57 (65%)Ships in 1-2 Business Days

| Page 1 of 2 |Next >

1-20 of 27 Results

Pontiac Firebird Intake Valve

The Intake Valve in Pontiac Firebird cars has the overall responsibility of improving the capabilities of the car engine, and facilitating efficient combustion of fuel. Its main role is to control the admission of of air and fuel into the engine and thus requires a proper sequence of operations. Cohesively, failure of the Intake Valve affects the combustion process, and therefore results in low power output, this makes replacement critical due to the expensive repairs involved. Intake Valves of Pontiac Firebird models have been developed in several styles over the years. Replacing a damaged Intake Valve requires several tasks, which includes using of some tools like valve spring compressor and small magnet for removal of valve spring. Proper installation is crucial in order to retain the structural and mechanical qualities of the car's engine and thereby make the Pontiac Firebird to remain efficient.

Each OEM Pontiac Firebird Intake Valve we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Firebird Intake Valve Parts Questions & Experts Answers

- Q: Is servicing Exhaust Valve and Intake Valve, valve seats, and valve guides best handled by a professional on Pontiac Firebird?A:Because of the challenge involved and the kind of equipment needed to work on the valves, the valve seats, and the valve guides it is advisable to engage the services of a professional. Home mechanic can take off and unbolt the head, perform rudimentary thorough washing and examination of the head and then he/she can present it to a dealer service department, or to a professional automotive machine shop for the actual valve servicing. The service department or the machine shop will have to have to strip the valves and springs, recondition or replace according to the need, inspect and replace the valve springs as contained in the specification, also replace the retainers, rotators and keepers if need be, replace the valve seals, reassemble the part and finally correctly set the installed spring height. Further, Cylinder head gasket surface will be grind as well if it is warped. That is always the case after performing the valve job, and the head will be almost as good as new. It should be washed before being placed in the head on the engine so as to purge it of any metal chips and sand that may be left behind during the service or after resurfacing. Compressed air should be utilised, if available, to blow out all oil holes and passages.

Related Pontiac Firebird Parts

Browse by Year

2002 Intake Valve 2001 Intake Valve 2000 Intake Valve 1999 Intake Valve 1998 Intake Valve 1997 Intake Valve 1996 Intake Valve 1995 Intake Valve 1994 Intake Valve 1993 Intake Valve 1992 Intake Valve 1991 Intake Valve 1990 Intake Valve 1989 Intake Valve 1988 Intake Valve 1987 Intake Valve 1986 Intake Valve 1985 Intake Valve 1984 Intake Valve 1983 Intake Valve 1982 Intake Valve