My Garage

My Account

Cart

Genuine Pontiac G6 Flywheel

Clutch Flywheel- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

4 Flywheels found

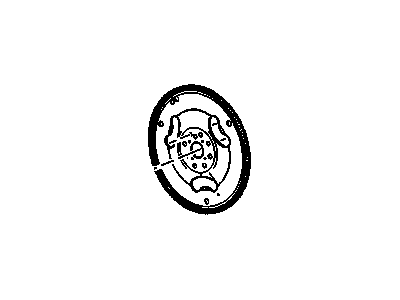

Pontiac G6 Automatic Transmission Flexible Plate Assembly

Part Number: 12647333$130.49 MSRP: $215.96You Save: $85.47 (40%)Ships in 1-3 Business DaysPontiac G6 Automatic Transmission Flexible Plate Assembly

Part Number: 12597026$63.26 MSRP: $100.90You Save: $37.64 (38%)Ships in 1-2 Business DaysPontiac G6 Engine Crankshaft Flywheel

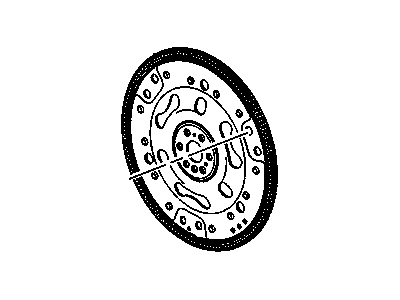

Part Number: 12577214$378.91 MSRP: $626.86You Save: $247.95 (40%)

Pontiac G6 Flywheel

Each OEM Pontiac G6 Flywheel we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac G6 Flywheel Parts Questions & Experts Answers

- Q: How to Remove and Install the Flywheel/Driveplate and Inspect for Leaks in 3.5L,3.9L V6 engine on Pontiac G6?A:Before any disassembly it is necessary to lift the car and secure it to jackstands, to pull out the transaxle. After that, undo the bolts which joins the flywheel or the driveplate to the crankshaft, making sure that alignment is marked if there is no dowel pins. If the crankshaft turns, use a screwdriver to jam the flywheel/driveplate. Any orientation of a retaining ring when remove needs to be noted. With much care, remove the flywheel/driveplate then put on gloves to avoid coming into contact with sharp edges. Scrub the flywheel/driveplate for the removal of any grease and oil and look fro cracks and warpage on a flat surface. Also, the flywheel/drive plate mating surfaces and crankshaft mating surface must be cleanned and inspected; the crankshaft rear seal must be replaced if leaking. During installation, the flywheel/driveplate must be placed on the crankshaft in a way that the previously made alignment marks match; the bolts should be washed with thread locking compound and the retaining ring placed at the same time. In fact, it is recommended to make use of the screwdriver to lock up the flywheel/driveplate so as to prevent it from rotating even as the bolts are tightened to the stipulated torque. If front pump seal or O-ring is bad, replace them at this time. The following steps are as follows and are performed in the reverse order of the removal of structures.