My Garage

My Account

Cart

Genuine Pontiac Grand Prix ABS Control Module

Anti Lock Brake Control Module- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

37 ABS Control Modules found

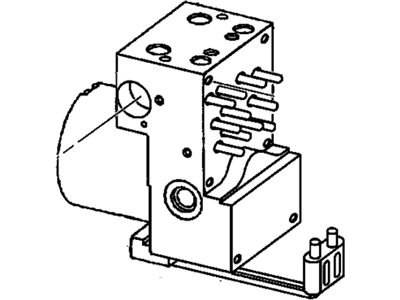

Pontiac Grand Prix Brake Pressure Modulator Valve (W/ Electronic Brake)

Part Number: 10435600$619.98 MSRP: $984.33You Save: $364.35 (38%)Ships in 1-3 Business DaysPontiac Grand Prix Abs Control Module, Electronic Brake Control Module Assembly

Part Number: 16159331Pontiac Grand Prix Brake Pressure Modulator Valve Assembly (W/ Electronic Brake)

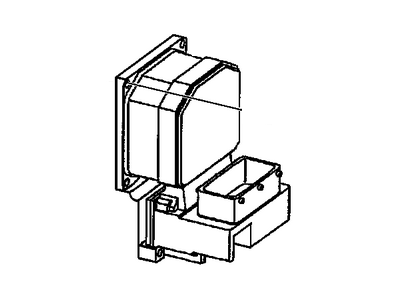

Part Number: 10326036Pontiac Grand Prix MODULE ASM,ELEK BRK CONT (REMAN)

Part Number: 19416832$473.02 MSRP: $856.15You Save: $383.13 (45%)Pontiac Grand Prix Electronic Traction Control Brake Pressure Module Valve Motor Kit

Part Number: 1997172Pontiac Grand Prix Abs Control Module, Electronic Brake Control Module Assembly

Part Number: 19121326Pontiac Grand Prix Brake Pressure Modulator Valve Assembly (W/ Elek Brk Cont Mdl)<See Bfo

Part Number: 19416843| Page 1 of 2 |Next >1-20 of 37 Results

Pontiac Grand Prix ABS Control Module

The main purpose of the Pontiac Grand Prix ABS Control Module is to manage the functions of the anti-lock braking system which helps the wheels to from locking up particularly in the case of hard braking. This module makes sure that the wheels do not lose contact with the ground thus improves the control of the vehicle and safety. This is made possible by the use of wheel speed sensor for the assessment of conditions, the use of valves for control of brake pressure, a pump in supply of hydraulic pressure and an ECU that helps control the force of the brake through assessment of data from the wheel speed sensor. Different versions of ABS Control Module have been featured in Pontiac Grand Prix over the years with change in technology as seen by features such as electronic stability control and traction control. Such alterations enable increased control over the automobile during skid and also increase the control of the brake force action during acceleration. What must first be understood with ABS is the fact that while it will commonly produce shorter stopping distances on most surfaces, it will occasionally produce longer stopping distances on loose gravel in particular or snow as heard here with this 2000 Pontiac Grand Prix, and therefore the different ABS Control Module present in each variation of the Pontiac Grand Prix must also be considered.

Each OEM Pontiac Grand Prix ABS Control Module we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Grand Prix ABS Control Module Parts Questions & Experts Answers

- Q: What Is the Function and Diagnostic Procedure for Anti-lock Brake Systems and ABS Control Module on Pontiac Grand Prix?A:Anti-lock Brake Systems (ABS) enhance vehicle maneuverability, directional stability, and optimal deceleration during severe braking on various road surfaces by monitoring wheel rotational speed and controlling brake line pressure to prevent wheel lock-up on slippery roads or during hard braking. The hydraulic modulator/motor pack assembly, located on the side of the master cylinder, regulates hydraulic pressure to the front calipers and rear wheel cylinders or calipers to prevent lock-up. The Electronic Brake Control Module (EBCM), positioned under the left side of the dash in models through 1998 and integrated into the motor/modulator assembly in later models, oversees the ABS system and manages the anti-lock valve solenoids by processing information from the brake switch and wheel speed sensors. Each sensor assembly features a variable reluctance sensor and a toothed ring, with the air gap between them being non-adjustable and the sensors non-rebuildable; any malfunction necessitates replacement. A wheel speed sensor generates an AC voltage signal proportional to wheel speed as the toothed ring rotates, and the EBCM activates the ABS system upon detecting sudden wheel deceleration. The ABS system includes self-diagnostic capabilities, with warning lights on the instrument panel: a red BRAKE light indicating issues with the main braking system, an amber ABS light signaling ABS system problems, and a blue LOW TRAC light. Preliminary checks that can be performed by a home mechanic include inspecting Brake Calipers, checking the electrical connector at the controller, verifying fuses, and ensuring secure connections and undamaged wiring to the speed sensors and Brake Light Switch; if issues persist, professional diagnosis is recommended.

Related Pontiac Grand Prix Parts

Browse by Year

2008 ABS Control Module 2007 ABS Control Module 2006 ABS Control Module 2005 ABS Control Module 2004 ABS Control Module 2003 ABS Control Module 2002 ABS Control Module 2001 ABS Control Module 2000 ABS Control Module 1999 ABS Control Module 1998 ABS Control Module 1997 ABS Control Module 1996 ABS Control Module 1995 ABS Control Module 1994 ABS Control Module 1993 ABS Control Module 1992 ABS Control Module 1991 ABS Control Module 1990 ABS Control Module 1989 ABS Control Module 1987 ABS Control Module 1986 ABS Control Module 1985 ABS Control Module 1984 ABS Control Module