My Garage

My Account

Cart

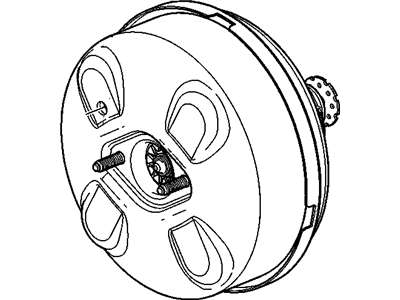

Genuine Pontiac Grand Prix Brake Booster

Brake Power Booster- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

11 Brake Boosters found

Pontiac Grand Prix Brake Booster

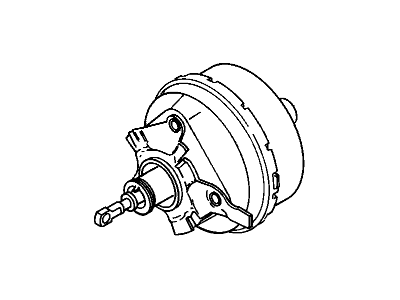

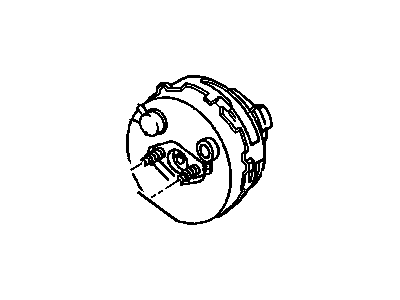

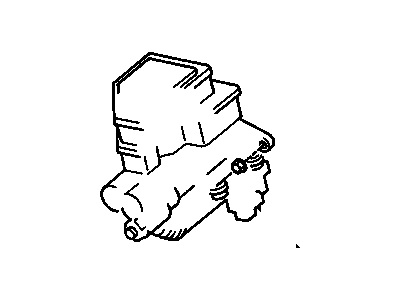

Pontiac Grand Prix comes equipped with a Brake Booster which proves helpful in improving the car's braking mechanism and the efforts applied by the driver. Located between the brake pedal and the master cylinder it employs vacuum or hydraulic technology to increase the force exerted while braking. Vacuum operated boosters are operated on the difference between engine vacuum and atmospheric pressure while hydraulic boosters use power steering pump fluid pressure or an electric motor. Through the years, Pontiac Grand Prix models have used different types of Brake Booster, single diaphragm and dual diaphragm up to our knowledge, in different diameters and different types of finish. In general, the boosters with a larger diameter are able to deliver more assistance, yet it is possible to achieve a similar level of help from dual diaphragm boosters even in case of rather constrained engine compartments.

Each OEM Pontiac Grand Prix Brake Booster we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Grand Prix Brake Booster Parts Questions & Experts Answers

- Q: What maintenance is required for the power brake booster unit on Pontiac Grand Prix?A:The power brake booster unit requires no special maintenance apart from periodic inspection of the vacuum hose and case. To check operation, depress the brake pedal several times with the engine off to ensure there is no change in the pedal reserve distance. Starting the engine while depressing the pedal should result in a slight drop, indicating normal operation. For an airtightness check, start the engine and turn it off after one or two minutes, then depress the pedal several times slowly; if the pedal goes down farther initially but rises after subsequent depressions, the booster is airtight. While the engine is running, stopping it with the brake pedal depressed should show no change in pedal reserve travel after 30 seconds, confirming airtightness. For removal on 1988 through 1990 models, special tools are required, and if a problem arises, a new or factory rebuilt unit should be installed. Remove the nuts attaching the master cylinder to the booster and carefully pull it forward, avoiding bending the Brake Lines. Disconnect the vacuum hose from the power brake booster and from the passenger compartment, disconnect the power brake pushrod from the brake pedal. Remove the nuts attaching the booster to the firewall, then carefully lift the booster away. For 1991 and later models, the same removal process applies, with the addition of removing the cross-vehicle brace on 2002 models. Caution is advised for ABS equipped models through 1998, as the master cylinder should not be disconnected from the hydraulic modulator assembly. After disconnecting the vacuum hose, it may be necessary to remove components like the upper intake plenum or acoustic engine cover, depending on the engine type. Disconnect the brake pushrod from the brake pedal while preventing the pedal from moving to avoid damaging the brake switch. The booster is mounted to the firewall with a "cam-lock" bracket; use a screwdriver to pry the locking tab out of the notch. If the factory tool is unavailable, a large strap wrench or rubber fuel hose can be used to assist in removal. Rotate the booster counterclockwise to free it from the bracket, taking care not to damage the boot around the pushrod. Installation is the reverse of removal, ensuring the locking tab is seated in the firewall bracket slot, followed by careful testing of the brake operation before driving.

Related Pontiac Grand Prix Parts

Browse by Year

2008 Brake Booster 2007 Brake Booster 2006 Brake Booster 2005 Brake Booster 2004 Brake Booster 2003 Brake Booster 2002 Brake Booster 2001 Brake Booster 2000 Brake Booster 1999 Brake Booster 1998 Brake Booster 1997 Brake Booster 1996 Brake Booster 1995 Brake Booster 1994 Brake Booster 1993 Brake Booster 1992 Brake Booster 1991 Brake Booster 1990 Brake Booster 1989 Brake Booster 1988 Brake Booster 1987 Brake Booster 1985 Brake Booster 1984 Brake Booster 1983 Brake Booster 1982 Brake Booster