My Garage

My Account

Cart

Genuine Pontiac Grand Prix Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

46 Brake Lines found

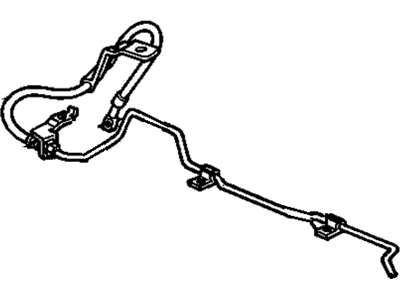

Pontiac Grand Prix Rear Brake Pipe Assembly

Part Number: 10407740$21.90 MSRP: $41.32You Save: $19.42 (47%)Ships in 1-2 Business DaysPontiac Grand Prix Pipe,Brake (Bulk Tubing 5/16" 8Mm)

Part Number: 12541500$38.53 MSRP: $63.76You Save: $25.23 (40%)Ships in 1-3 Business DaysPontiac Grand Prix Hose Assembly, Front Brake (Rh)

Part Number: 10112054$22.74 MSRP: $42.90You Save: $20.16 (47%)Ships in 1-2 Business DaysPontiac Grand Prix Rear Brake Hose Assembly

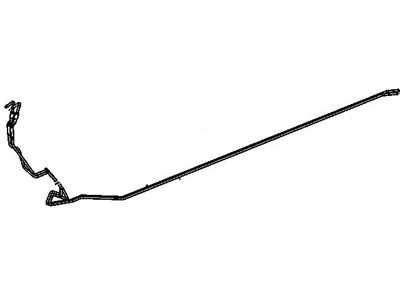

Part Number: 22163167$26.53 MSRP: $50.05You Save: $23.52 (47%)Ships in 1-2 Business DaysPontiac Grand Prix Rear Brake Hose Assembly

Part Number: 19173804$9.73 MSRP: $18.35You Save: $8.62 (47%)Ships in 1-3 Business DaysPontiac Grand Prix Front Brake Hose Assembly

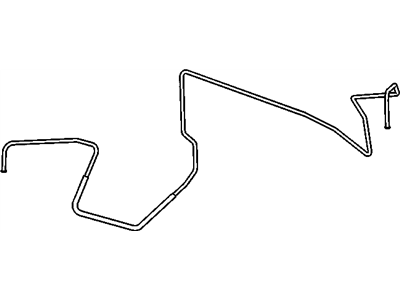

Part Number: 19169839$12.37 MSRP: $22.19You Save: $9.82 (45%)Pontiac Grand Prix Rear Brake Hose Assembly

Part Number: 19173567$21.44 MSRP: $40.47You Save: $19.03 (48%)Ships in 1-3 Business DaysPontiac Grand Prix Rear Brake Hose Assembly

Part Number: 19173568$21.23 MSRP: $40.06You Save: $18.83 (47%)Ships in 1-3 Business DaysPontiac Grand Prix Front Brake Hose Assembly

Part Number: 19366668$23.80 MSRP: $34.20You Save: $10.40 (31%)

| Page 1 of 3 |Next >

1-20 of 46 Results

Pontiac Grand Prix Brake Line

The Brake Line in vehicles specifically the Pontiac Grand Prix is responsible for transmitting brake fluid from the master cylinder to the brake caliper pistons so that the hydraulic brake system can work efficiently. This system is important for the safe operation of the car in that the car has to stop or reduce its speed when the brake is applied. In models of the Pacific fleetside conversion automobile, the Grand Prix, distinct types of Brake Lines have been employed with being metal brake lines and rubber brake hoses. There are problems with metal lines which include corrosion as well as impact issues, rubber hoses meanwhile have issues to do with cracks and internal damage. For those who want to get a more rigid brake pedal feel especially when driving hard is highly recommended for the use of braided stainless steel Brake Lines than the usual rubber hoses.

Each OEM Pontiac Grand Prix Brake Line we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Grand Prix Brake Line Parts Questions & Experts Answers

- Q: How often should you check the flexible hoses connecting the steel brake lines to the brake assemblies, and what steps should you follow to replace them on Pontiac Grand Prix?A:Every six months approximately, lift the car and safely support it on jackstands to inspect the flexible hoses which connect the steel brake lines to the front and rear brake units as these hoses are quite essential and rather susceptible to cracks, abrasion, leaks, blisters or bulges and any of these should call for replacement of the affected hose with a new one; it will be advisable to use a light and a mirror while inspecting areas that can hardly To replace the front brake hose to start off, undo the brake line from the hose fitting using a back-up wrench and then remove the 'U' clip from the female end at the bracket and also removing the hose from the bracket. At the caliper end remove the bolt securing the fitting block, after that the hose and copper washers. On fitting a new hose, always fit new copper washers and before tightening bolt apply clean brake fluid to the threads of the bolt and ensure that the fitting flange goes under the caliper locating ledge before connecting the hose. Make sure the hose does not twist and put the female fitting inside the hose bracket and fasten it with a clip; next tighten the brake line to the female hose fitting with back-up wrench. After the installation, check to be sure that the hose is not kinked and does not come into contact with its suspension part by sharply turning the wheels to the left and to the right. For the rear brake hose, first way it with back-up wrench at both ends, then remove the U-clip, unbolt the hose retaining clip and put the female ends into the frame bracket without twisting. Screw the female end with the help of the U-clip and then fit the steel line fittings such that tightens the frame bracket. Refill master cylinder reservoir and carryout bleed procedure. When removing metal brake line, it is advised to replace it with the similar type, not to use copper or other type of tubing, there are prefabricated brake line available in auto part stores. If prefabricated lines are not available get recommended steel tubing and fittings, then you measure the old brake line and cut that of the new tubing flare the ends then fit the fittings. If necessary to put it through the desired shape, use the tube bender frequently to support the place where the line contacts the brackets with a safety clearance from other moving or hot parts. These steps are performing after installation, checking the fluid level of the master circuit, putting the fluid if available, bleaching the system and testing the brakes before operating it on the traffic.

Related Pontiac Grand Prix Parts

Browse by Year

2008 Brake Line 2007 Brake Line 2006 Brake Line 2005 Brake Line 2004 Brake Line 2003 Brake Line 2002 Brake Line 2001 Brake Line 2000 Brake Line 1999 Brake Line 1998 Brake Line 1997 Brake Line 1996 Brake Line 1995 Brake Line 1994 Brake Line 1993 Brake Line 1992 Brake Line 1991 Brake Line 1990 Brake Line 1989 Brake Line 1988 Brake Line 1987 Brake Line 1986 Brake Line 1985 Brake Line 1984 Brake Line