My Garage

My Account

Cart

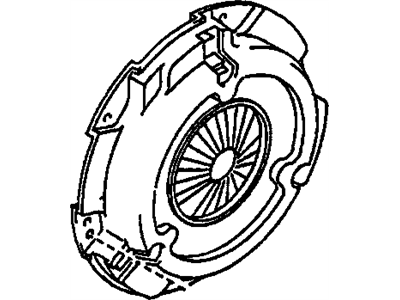

Genuine Pontiac Grand Prix Pressure Plate

Clutch Pressure Plate- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

2 Pressure Plates found

Pontiac Grand Prix Pressure Plate

In Pontiac Grand Prix vehicles the Pressure Plate functions as a critical clutch assembly element which both enables and disables the clutch disc from connecting to the flywheel. The Pressure Plate executes forceful clamping that enables engine power transmission to the transmission. By pressing the clutch pedal the Pressure Plate will release the clutch disc which makes it possible to change gears. Three types of Pressure Plates exist in Grand Prix models: diaphragm and borg and beck and long style. When driving for normal use the diaphragm Pressure Plate delivers smooth engagement through its belleville spring shape that also reduces the amount of pedal force needed. A comparison emerges between diaphragm Pontiac Pressure Plates and borg and beck and long style Pontiac Grand Prix replacement parts because the latter utilizes coil springs and levers which yield superior strength for racing conditions. A driving condition determines which type of clutch works optimal because each clatch system requires different operational characteristics.

Each OEM Pontiac Grand Prix Pressure Plate we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Grand Prix Pressure Plate Parts Questions & Experts Answers

- Q: How to Remove, Inspect and Replace Clutch Disc and Pressure Plate on Pontiac Grand Prix?A:The clutch components are more easily gotten to by removing the transaxle while leaving the engine in the vehicle; if the engine is removed for major rebuilding the clutch should be inspected and any defective parts replaced. First of all, it will be required to provide the transaxle and the Release Bearing removal. For the purpose of having support for the clutch disc during its removal a clutch alignment tool should be inserted through the splined hole. With your fingers, proactively look for indexing marks on the pressure plate and flywheel and; if missing, make your own to ease the repositioning of the assembly. Turn in the pressure plate to the fly-wheel in 1/4 turn intervals in a figure 8 pattern and then remove the pressure plate, clutch disc and the bolts. For models having a pull-type clutch, unbolt the wedge collar and the retainer ring from the pressure plate diaphragm spring. While inspecting the automobile, find out where the clutch driven plate assembly has worn out and check within the assembly if it has been contaminated by oil making it slip; also check on the flywheel to see if it has any defects and the clutch disc lining to find out if it is thick enough and if it has any signs of being damaged. Release bearing is often changed in parallel with the clutch disc-diaphragm spring fingers as well as the pressure plate surfaces have to be inspected for wear. It's recommended to clean the surfaces of the flywheel and pressure plate before installation and it is permissible that no oil or grease are used. In pull-type clutches ensure you do not damage the wedge collar and retainer ring when fixing them into place. Align the clutch disc and the pressure plate with the flywheel, with help of an alignment tool to ensure correct positioning. Tighten the bolts which holds the pressure plate to the flywheel until pretty tight, then align the clutch disc and tighten the bolts tightly, in the diagonal pattern to the prescribed torque. Grease the release lever fingers with high temperature grease and lubricate the inner trough of the release bearing if the clutch is of the push type. Last but not the least, fit the clutch release bearing, the transaxle, the slave cylinder and every other part that was removed in the process all without harming the wedge collar or the retainer ring when fitting the transaxle and then adjust the shift lever.