My Garage

My Account

Cart

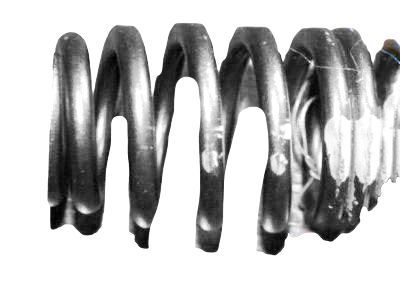

Genuine Pontiac Grand Prix Rocker Shaft Spring Kit

Rocker Shaft Spring Set- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

9 Rocker Shaft Spring Kits found

Pontiac Grand Prix Spring, Valve *Green Inside Diameter

Part Number: 10166343$13.05Ships in 1-3 Business DaysPontiac Grand Prix Spring, Valve (W/ Dampener)

Part Number: 3911068$9.01 MSRP: $14.18You Save: $5.17 (37%)Ships in 1-3 Business DaysPontiac Grand Prix SPRING, Engine Valve

Part Number: 1249267$13.05 MSRP: $18.75You Save: $5.70 (31%)Pontiac Grand Prix Spring Kit,Valve (W/Cap)

Part Number: 19257200$8.96 MSRP: $14.82You Save: $5.86 (40%)Ships in 1-3 Business DaysPontiac Grand Prix Spring, Valve

Part Number: 22548421$5.94 MSRP: $8.43You Save: $2.49 (30%)Ships in 1-2 Business Days

Pontiac Grand Prix Rocker Shaft Spring Kit

Each OEM Pontiac Grand Prix Rocker Shaft Spring Kit we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Pontiac Grand Prix Rocker Shaft Spring Kit Parts Questions & Experts Answers

- Q: How can broken Rocker Shaft Spring Kit and Valve Stem Oil Seal be replaced without removing the cylinder head in 3.4L V6 engine on Pontiac Grand Prix?A:That can be done without the removal of the cylinder head, and it has been reported that only two special tools and compressed air are needed. Lacking a source of compressed air, one can use a piece of nylon cord to secure the valves in the proper position, so they wouldn't accidentally fall to the bottom of the cylinder. Start by the elimination of the cam carrier and the spark plugs from the cylinders in question, regardless of the number of valve stem seals that will be replaced, all the plugs should be taken out. Rotate the crankshaft until the piston of the cylinder to be checked is positioned at the TDC, this should be done cylinder by cylinder strictly on the firing order bases. Insert an adapter into the spark plug hole and attach an air hose to this unit from the compressed air. Use compressed air on the cylinder, careful that you do not force the piston down as this may cause the crankshaft to rotate. The air pressure is said to keep the valves tightly abreast; in the event that there are problems in this aspect, a valve grinding may be required. If nylon rope is to be used, the piston must be just prior to TDC, the combustion chamber filled with the rope, and the crankshaft turned until slight pressure is encountered. Shove pieces of paper into the ports of the cylinder head to avoid dropping 'things' then compress the valve spring using the spring compressor to remove the keepers. When you have fully dismantled the engine, stripping the engine completely, to get at the essential components of the engine you have to unscrew the spring retainer and valve spring then you remove the valve guide seal. Tie the fatty valve stem with a rubber band or tape for it not to droop, if using rope, either blow out the pressure or slightly turn the crankshaft in the opposite direction. Check the condition of the valve stem with the movement of the head; if the stem is stiff to move in the guide, then head will require to be unbolted for necessary repairs. Maintain pressure on the air pressure to make the valve closed, untie the tape or rubber band, oil the valve stem with the engine oil and fit a new valve guide seal. Suspend the valve with the spring above the valve and insert the spring retainer in place, in order to compress the spring, the keepers should be carefully inserted into the retainer, the greasing them for them to hold in place tightly. Release the air hose, unscrew the adapter, screw the spark plugs back and wire them, put back the cam carrier. Last but not the least, turn on the engine and look for signs of oil dripping and any strange sound coming from the area of the valve cover.

Related Pontiac Grand Prix Parts

Browse by Year

2008 Rocker Shaft Spring Kit 2007 Rocker Shaft Spring Kit 2006 Rocker Shaft Spring Kit 2005 Rocker Shaft Spring Kit 2004 Rocker Shaft Spring Kit 2003 Rocker Shaft Spring Kit 2002 Rocker Shaft Spring Kit 2001 Rocker Shaft Spring Kit 2000 Rocker Shaft Spring Kit 1999 Rocker Shaft Spring Kit 1998 Rocker Shaft Spring Kit 1997 Rocker Shaft Spring Kit 1996 Rocker Shaft Spring Kit 1995 Rocker Shaft Spring Kit 1994 Rocker Shaft Spring Kit 1993 Rocker Shaft Spring Kit 1992 Rocker Shaft Spring Kit 1991 Rocker Shaft Spring Kit 1990 Rocker Shaft Spring Kit 1989 Rocker Shaft Spring Kit 1988 Rocker Shaft Spring Kit 1987 Rocker Shaft Spring Kit 1986 Rocker Shaft Spring Kit 1985 Rocker Shaft Spring Kit 1984 Rocker Shaft Spring Kit 1983 Rocker Shaft Spring Kit 1982 Rocker Shaft Spring Kit