My Garage

My Account

Cart

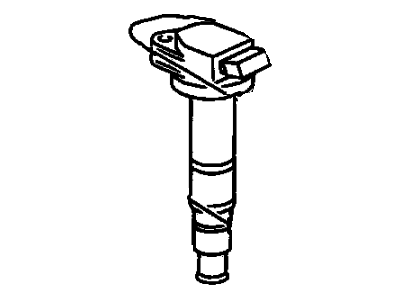

Genuine Pontiac Ignition Coil

Ignition Coil Resistor- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

34 Ignition Coils found

- Product Specifications

- Other Name: Coil Assembly, Ign; Coil, Ignition Coil

- Replaced by: 12739916

- Replaces: 12573190

Pontiac Ignition Coil Assembly

Part Number: 25186687$74.32 MSRP: $243.94You Save: $169.62 (70%)Ships in 1 Business DayProduct Specifications- Other Name: Coil Assembly, Ignition; Ignition Coil

- Replaced by: 12735943

- Replaces: 96476983, 55561655

Pontiac Ignition Coil Assembly

Part Number: 12353801$113.53 MSRP: $234.30You Save: $120.77 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil Kit, Electronic Ignition ; Coil, Ignition Coil; Coil, Ignition Coil

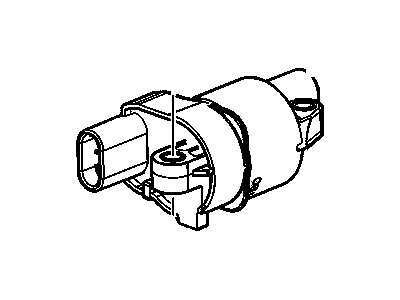

- Product Specifications

- Other Name: Coil,Distributor Pick Up ; Coil, Ignition; Coil, Ignition Coil, Pick-Up Coil

- Replaces: 01987964, 1987964

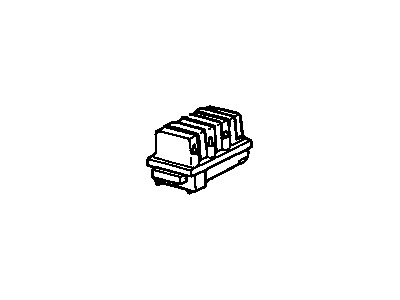

- Product Specifications

- Other Name: Coil,Ignition; Coil

- Replaced by: 12739916

- Replaces: 12570616

Pontiac COIL ASM,IGN

Part Number: 19418996$70.67 MSRP: $145.86You Save: $75.19 (52%)Ships in 1-3 Business DaysProduct Specifications- Other Name: Ignition Coil

- Replaces: 10489421, 19207138

Pontiac COIL ASM,IGN

Part Number: 19418991$52.18 MSRP: $107.70You Save: $55.52 (52%)Ships in 1 Business DayProduct Specifications- Other Name: Coil, Coil Assembly, Ignition Coil

- Replaces: 10472401, 10482928, 19353734

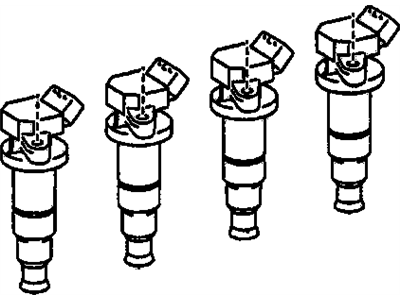

Pontiac COIL KIT,IGN

Part Number: 19418995$41.50 MSRP: $114.58You Save: $73.08 (64%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil, Ignition Coil

- Replaces: 01115468, 12498334, 01115315, 1115315, 1115468

- Product Specifications

- Other Name: Ignition Coil

- Replaces: 12556450, 12558948

Pontiac Ignition Coil Assembly

Part Number: 25182496$104.69 MSRP: $216.06You Save: $111.37 (52%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil Asm,Ignition; Ignition Coil

- Replaces: 96253555

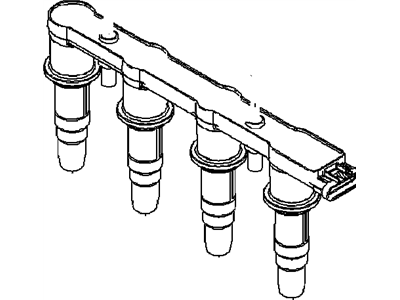

Pontiac Ignition Coil Kit

Part Number: 12498336$73.53 MSRP: $151.76You Save: $78.23 (52%)Ships in 1 Business DayProduct Specifications- Other Name: Coil Kit,Ignition ; Coil, Ignition Coil; Coil, Ignition Coil

- Replaces: 01985474, 1985474

Pontiac Ignition Coil Assembly

Part Number: 19205387$79.47 MSRP: $149.92You Save: $70.45 (47%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil Asm,Ignition ; Coil, Ignition Coil; Ignition Coil

- Replaces: 19185426

Pontiac Ignition Coil

Part Number: 94859442$58.50 MSRP: $100.00You Save: $41.50 (42%)Ships in 1-2 Business DaysProduct Specifications- Other Name: Coil,Ignition

Pontiac Ignition Coil

Part Number: 19166375$54.06 MSRP: $101.99You Save: $47.93 (47%)Ships in 1 Business DayProduct Specifications- Other Name: Coil,Ignition; Coil

- Replaces: 10474481, 10457062, 10457109, 10472748

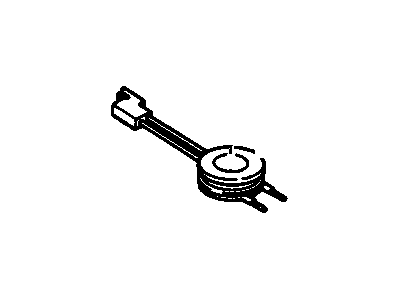

- Product Specifications

- Other Name: Coil,Ignition Distributor.

- Replaced by: 19166375

- Product Specifications

- Other Name: Coil,Ignition; Coil Assembly, Ignition Module

- Replaces: 12585765

- Product Specifications

- Other Name: Coil Asm,Ignition ; Coil, Ignition Coil; Ignition Coil

- Product Specifications

- Other Name: Coil Asm,Ignition Kit; Coil, Ignition Coil

- Replaces: 10477602

- Product Specifications

- Other Name: Coil,Ignition; Coil, Ignition Module

- Product Specifications

- Other Name: Coil,Ignition

| Page 1 of 2 |Next >

1-20 of 34 Results

Pontiac Ignition Coil

If you're searching for OEM Pontiac Ignition Coils, look no further. Our website boasts an extensive inventory of genuine Pontiac Ignition Coils, all available at competitive prices online. Every part we offer comes with a manufacturer's warranty. In addition, we provide a straightforward return policy and rapid delivery services, making your shopping experience a breeze.

Pontiac Ignition Coil Parts Questions & Experts Answers

- Q: How to replace the ignition coil on Pontiac Fiero?A:Start by removing the cap and rotor of the distributor, then remove the distributor itself. Disconnect the pick-up coil leads from the module and use an ohmmeter to test for any faults. There is a need for flexing by hand to identify intermittent opens on the leads with infinity reading at all times on the ohmmeter. Then, connect one end of an ohmmeter to the pick-up coil lead terminal and flex it again checking for intermittent opens as it flexes, with a constant meter reading of 500-1500 ohms. If any of these tests fail, it means that there is a bad pick-up coil. To replace it, mark the distributor gear and shaft for reassembly in the same position, take out roll pin from distributor shaft and gear, and pry off retaining ring. Pull straight up on pick-up assembly and wipe distributor base and module clean before applying silicone lubricant between module base for heat dissipation. Drop in module attaching module base then connect pick-up pole piece assy., retainer assy., install shaft gear parts, roll pin. Ensure that teeth do not touch; after this install rotor/cap then final re-installation of distributor into engine must be made. For V6 remove distibutor from engine; disconnect wiring connector at cap; turn four latches to remove cap/coil assembly from lower housing. Take out rotor and pickup coil lead wires from ignition module. When testing an ohmmeter should be connected between pickup coil lead connector & distributor housing reading infinite resistance. Connect an ohmeter between both terminals of pickup coil lead connector and note steady values between 600-1600 ohms will indicate that you have good ones. If any of these tests fail, it indicates that there is something wrong with its pick-up coil. To replace it: mark distibutor shaft/gear for reassembly; drive out roll pin; remove gear then draw shaft out of distributor. Next, remove the magnetic shield by removing three attaching screws, followed by detaching pick-up coil, magnet and pole piece by taking off C-clip. Put back a new pick-up coil, magnet and pole piece with a thin washer, then reassemble the shaft/gear parts/roll pin making sure teeth do not touch. Inserting rotor/cap then finally reinstalling distributor into engine that is all.

- Q: How to check Ignition Coil on Pontiac Firebird?A:To check coil-in-cap models, start by removing the distributor cap and using an ohmmeter to measure the resistance across the TACH and BAT terminals at the distributor cap. The resistance should be very low. Then, switch the meter to the high scale and measure the resistance between the TACH terminal and the SECONDARY terminal, as well as the GROUND terminal and the SECONDARY terminal. If both readings are infinite, replace the coil. Next, disconnect the wiring connectors from the distributor cap and remove the spark plug wiring harness retainer clips. Rotate the distributor cap locking latches counterclockwise to remove the cap. Remove the coil cover and separate the coil and leads from the cap. Replace the carbon button and arc seal. For models with separately mounted coils, disconnect the wiring connectors and secondary ignition wire from the coil. Use an ohmmeter to measure the primary and secondary coil resistance, checking for an open circuit or short to ground. Replace the coil if it fails any of the tests. To replace the coil, disconnect the wiring connectors and secondary ignition wire, loosen the coil bracket mounting nuts, and remove the coil. Installation is the reverse of the removal procedure.

Related Pontiac Parts

Browse by Model

6000 Ignition Coil Aztek Ignition Coil Bonneville Ignition Coil Fiero Ignition Coil Firebird Ignition Coil G3 Ignition Coil G5 Ignition Coil G6 Ignition Coil G8 Ignition Coil GTO Ignition Coil Grand Am Ignition Coil Grand Prix Ignition Coil J2000 Ignition Coil LeMans Ignition Coil Montana Ignition Coil Parisienne Ignition Coil Phoenix Ignition Coil Pursuit Ignition Coil Safari Ignition Coil Solstice Ignition Coil Sunbird Ignition Coil Sunfire Ignition Coil Sunrunner Ignition Coil T1000 Ignition Coil Torrent Ignition Coil Trans Sport Ignition Coil Vibe Ignition Coil