My Garage

My Account

Cart

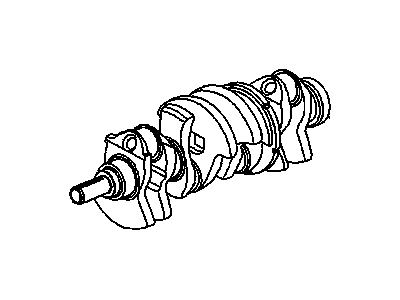

Genuine Saturn Vue Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

5 Crankshafts found

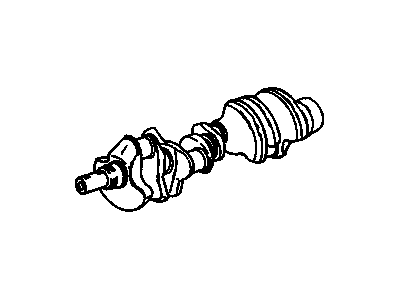

Saturn Vue Engine Crankshaft

Part Number: 12623074$564.05 MSRP: $933.17You Save: $369.12 (40%)Ships in 1-3 Business DaysSaturn Vue Engine Crankshaft

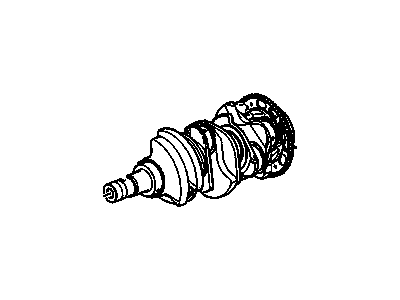

Part Number: 90509018$296.63 MSRP: $1800.76You Save: $1504.13 (84%)Ships in 1-2 Business Days

Saturn Vue Crankshaft

Each OEM Saturn Vue Crankshaft we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Saturn Vue Crankshaft Parts Questions & Experts Answers

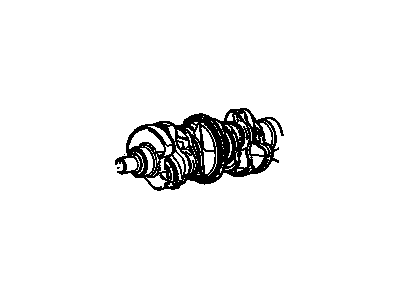

- Q: How can the crankshaft be removed and reinstalled on Saturn Vue?A:Indeed, the crankshaft is one of the few components that can only be accessed when the engine is removed from the car, provided that such WI bits as the driveplate, crankshaft pulley, timing belt or chain, oil pan, oil pump body, oil filter and Piston/connecting rod assemblies are already removed. Before removal, and with the crankshaft suitably aligned, use a dial-gauge to take a reading of the amount of crankshaft endfloat. Place the indictor blade on the counter surface, pry the crankshaft to the rear and rotate the indicator zero, then pry the crankshaft to the front and observe the dial which should show a total indicator movement of .003 in. to .010 in. (0.076mm-0.254mm). In a situation where a dial indicator is not available, clearance can be measured with the aid of feeler gauges. Take out half of the main bearing bolts to independently pedals that can be rotated, then gently drill the main bearing caps or bridge on the bulkhead with a soft-steel hammer and lift it up. Remove the crankshaft as delicately as possible, because of its weight which should be manageable by two people, then reinsert the main bearing caps with the arrow facing forward. Installation requirements include that the engine block, crankshaft should be clean and checked. At this stage, position the engine block upside down and you have to remove the main bearing caps and clean the bearing surfaces. The new upper main bearing inserts should be installed in the block, and lower inserts on to the caps in the right manner. Scrub the crankshaft and make certain the oil holes are clear of dirt. Place the crankshaft on the main bearings and perform a Plastigage measurement of the main bearing oil clearance should be within the set limit. If the clearance is incorrect the observer should check that no debris was present at the time of the measurement and should consider changing the bearing inserts if needed. When the Plastigage is removed, coat the bearing surfaces and the crankshaft journals with a layer of grease or assembly lube then place the main bearing caps and make sure that the arrow faces the front. After tightening the bolts, ensure that they are tightened in the correct order and for some of the engine types, turn the sleeves then apply sealant if required. Last but not the least, verify the crankshaft end play and make it free to rotate with little or no drag by sorting it out before fitting of a new rear main oil seal.