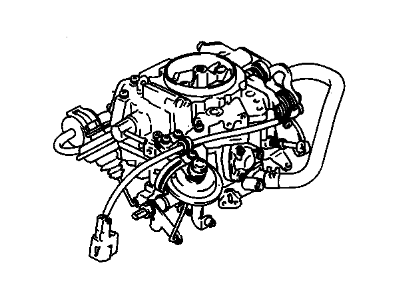

An inspection and road test should be carried out prior to any major service work as carburetor malfunctions only reveal themselves when the vehicle floods, hard to start, stalls, has a rich backfire and poor performance. One that is either leaking or one that has a wet deposit on its surface needs to be dealt with as soon as possible. Sources of performance complaints include the way loose or malfunctioning engine component, vacuum hose, or incorrect routing. Carburetor issues that need to be looked at include issues with vacuum hoses and actuators, intake manifold and carburetor fasteners to be tightened, cylinder compression test, the cleaning or replacement of spark plugs and wires, the inspection of the ignition primary wires, and the timing of the ignition, as well as the fuel pump and heat control valve. Moreover, it is recommended as well to examine the condition of its air filter, PCV system, fuel filter, exhaust system, EGR valve, position of the choke, signs of fuel leakage, accelerator pump, quality of fuel used, and the clearance of the valves. If so, a dealer or repair should ensure that they examine the electronic engine and carburetor controls. Performing diagnostic may demand idling the engine without the air cleaner, a practice which may result to backfires if the carburetor is flawed. In the event of a rebuild, choices include the purchase of a top quality rebuild kit or a new/rebuilt carburetor, provided they are originals. During the overhaul, time for disassembling the engine, washing its parts in the cleaning solvent, and reassembling the engine should be taken since such an activity if done ineffectively due to inexperience will result in a poor performance of your engine. Because of continuous changes in the carburetor models due to emission requirements, instructions unique to the type of carburetor will be given out when disseminating overhaul kits.

Posted by GMPartsGiant Specialist