My Garage

My Account

Cart

Genuine 1999 Oldsmobile Cutlass Starter

Starter Ignition- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

1 Starter found

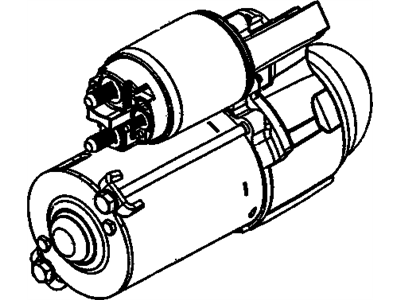

1999 Oldsmobile Cutlass Start Motor Assembly (Remanufacture)

Part Number: 10465459$112.35 MSRP: $339.90You Save: $227.55 (67%)Ships in 1-2 Business DaysProduct Specifications- Other Name: STARTER, Starter Motor; Starter

- Replaces: 10465384

- Item Weight: 8.20 Pounds

- Item Dimensions: 6.2 x 6.3 x 12.5 inches

- Condition: New

- Fitment Type: Direct Replacement

- SKU: 10465459

- Warranty: This genuine part is guaranteed by GM's factory warranty.

1999 Oldsmobile Cutlass Starter

We are your prime source for competitively priced and high-quality OEM 1999 Oldsmobile Cutlass Starter. We provide you with parts that will allow you to save a lot of money without sacrificing quality. All our OEM parts are backed by the manufacturer's warranty and shipped out at a swift rate.

1999 Oldsmobile Cutlass Starter Parts Questions & Experts Answers

- Q: Is it advisable for the home mechanic to purchase a new or factory-rebuilt starter motor unit instead of attempting to disassemble and test the existing one on 1999 Oldsmobile Cutlass?A: Due to the critical nature of disassembling and testing the starter, it may be advisable for the home mechanic to purchase a new or factory-rebuilt unit. If an overhaul is decided upon, check the availability of singular replacement components before proceeding. Begin by disconnecting the starter field coil connectors from the solenoid terminals, then unscrew and remove the through bolts. Next, remove the commutator end-frame, field frame assembly, and armature from the drive housing. Slide the two-section thrust collar off the end of the armature shaft, and using a suitable tube, drive the stop/retainer up the armature shaft to expose the snap-ring. Extract the snap-ring from its shaft groove, then slide the stop/retainer and overrunning clutch assembly from the armature shaft. Dismantle the brush components from the field frame and release the V-shaped springs from the brushholder supports. Remove the brushholder support pin and lift the complete brush assembly upwards. Disconnect the leads from the brushes if they are worn down to half their original length and need replacement. The starter is now completely dismantled except for the field coils; if these are found defective during testing, removal of the pole shoe screws is best left to a service station with the necessary pressure driver. Clean all components and replace any obviously worn parts. Avoid undercutting the insulation between the commutator segments on molded type commutators; for conventional types, undercut the insulation by 1/32 inch using an old hacksaw blade, ensuring the undercut is the full width of the insulation and the groove is square at the bottom. After undercutting, brush away all dirt and dust. Clean the commutator by spinning it with a piece of number sandpaper wrapped around it, avoiding any other type of abrasive material. If the commutator is in poor condition, it may be turned down in a lathe to provide a new surface, ensuring to undercut the insulation afterward. To test the armature for ground, use a lamp-type circuit tester by placing one lead on the armature core or shaft and the other on a segment of the commutator; if the lamp lights, the armature is grounded and must be replaced. To test the field coils for open circuit, place one test probe on the insulated brush and the other on the field connector bar; if the lamp does not light, the coils are open and must be replaced. To test the field coils for ground, place one test probe on the connector bar and the other on the grounded brush; if the lamp lights, the field coils are grounded. The overrunning clutch cannot be repaired and must be replaced as a complete assembly if faulty.