My Garage

My Account

Cart

Genuine Cadillac CTS Brake Line

Brake Hose- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

62 Brake Lines found

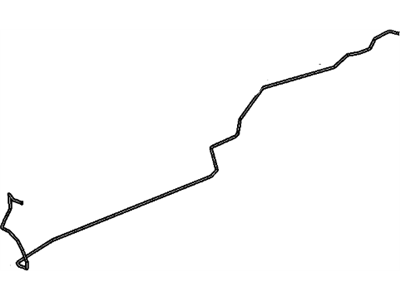

Cadillac CTS Pipe,Brake

Part Number: 88983905$68.37 MSRP: $134.44You Save: $66.07 (50%)Ships in 1-3 Business DaysCadillac CTS Rear Brake Hose Assembly

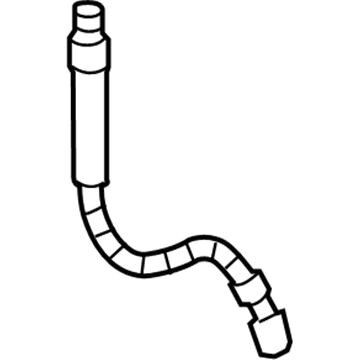

Part Number: 84238005$15.55 MSRP: $29.33You Save: $13.78 (47%)Ships in 1-2 Business DaysCadillac CTS Front Brake Hose Assembly

Part Number: 84237990$14.38 MSRP: $27.15You Save: $12.77 (48%)Ships in 1-2 Business DaysCadillac CTS Front Brake Hose Assembly

Part Number: 84237974$18.06 MSRP: $32.87You Save: $14.81 (46%)Ships in 1-2 Business DaysCadillac CTS Hose Kit,Front Brake

Part Number: 19256891$22.66 MSRP: $42.76You Save: $20.10 (48%)Ships in 1-2 Business DaysCadillac CTS Front Brake Hose Assembly

Part Number: 86538445$17.41 MSRP: $32.87You Save: $15.46 (48%)Ships in 1-2 Business DaysCadillac CTS Hose Kit,Front Brake

Part Number: 19256888$22.66 MSRP: $42.76You Save: $20.10 (48%)Ships in 1-2 Business DaysCadillac CTS Rear Brake Hose Assembly

Part Number: 20853832$14.80 MSRP: $27.95You Save: $13.15 (48%)Ships in 1-2 Business DaysCadillac CTS Front Brake Hose Assembly

Part Number: 23182556$24.38 MSRP: $46.00You Save: $21.62 (47%)Ships in 1-2 Business DaysCadillac CTS Hose Assembly, Front Brake

Part Number: 23182555$18.02 MSRP: $34.00You Save: $15.98 (47%)Ships in 1-2 Business DaysCadillac CTS Front Brake Hose Assembly

Part Number: 22837065$33.60 MSRP: $63.40You Save: $29.80 (47%)Ships in 1-2 Business DaysCadillac CTS Front Brake Hose Assembly

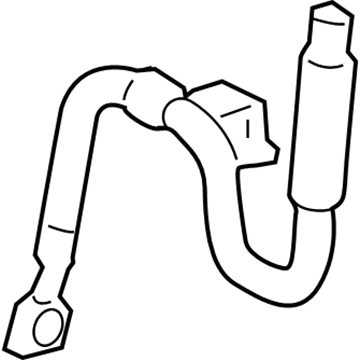

Part Number: 15818105$32.59 MSRP: $59.25You Save: $26.66 (45%)Ships in 1-2 Business DaysCadillac CTS Pipe Assembly, Brake Pressure Mod Valve (Primary)

Part Number: 22999195$29.61 MSRP: $53.83You Save: $24.22 (45%)Ships in 1-2 Business DaysCadillac CTS Pipe Assembly, Brake Pressure Mod Valve (Secondary)

Part Number: 22999196$23.06 MSRP: $43.49You Save: $20.43 (47%)Ships in 1-2 Business DaysCadillac CTS Pipe,Brake (Coated Bulk Pipe, 5/16In X 16Ft)

Part Number: 19181732$306.52 MSRP: $557.33You Save: $250.81 (45%)Ships in 1-2 Business DaysCadillac CTS Pipe Assembly, Brake Pressure Mod Valve (Secondary)

Part Number: 84334732$24.34 MSRP: $44.26You Save: $19.92 (46%)Ships in 1-2 Business DaysCadillac CTS Pipe Assembly, Brake Pressure Mod Valve (Primary)

Part Number: 84334733$24.34 MSRP: $44.26You Save: $19.92 (46%)Ships in 1-2 Business DaysCadillac CTS Front Brake Hose Assembly

Part Number: 15818106$25.41 MSRP: $45.57You Save: $20.16 (45%)Cadillac CTS Pipe Assembly, Brake Pressure Mod Valve Rear

Part Number: 25882805$70.17 MSRP: $125.85You Save: $55.68 (45%)

| Page 1 of 4 |Next >

1-20 of 62 Results

Cadillac CTS Brake Line

The Cadillac CTS Brake Line is highly involved in supplying brake fluid from the master cylinder to the brake caliper pistons so that the hydraulic braking system may run smoothly. Metal brake lines are also vulnerable to both corrosion and impact and the end result of both is the creation of leaks in the fluid as well as the hydraulic pressure. Another component that can get physical and internal damage is the brake hose which in turn will impact the performance of the brakes. Should replacement be required then preformed brake line kits and corrosion protected stainless steel brake hoses can therefore be used for fitting. Replacing it with the braided stainless steel hoses will yield a better feel on the pedals especially in performance driving situations.

Each OEM Cadillac CTS Brake Line we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac CTS Brake Line Parts Questions & Experts Answers

- Q: How to Inspect and Replace Flexible Brake Hoses and Brake Lines on Cadillac CTS?A:About every six months, it is important to inspect the flexible hoses that connect the steel brake lines with the front and rear brake assemblies for any cracks, chafing, leaks, blisters, or other damage. This inspection should be done with the vehicle raised and securely placed on jackstands, using a light and mirror for a thorough check. If any of the above defects are found, the hose should be replaced with a new one. To remove a brake hose, clean all dirt away from the ends and unscrew the tube nut with a flare-nut wrench. Remove the bolt(s) or clip(s) securing the hose to the body and disconnect it from the caliper, discarding the sealing washers. Attach the new brake hose to the caliper using new sealing washers and tighten the banjo fitting bolt to the specified torque. Make sure the hose isn't twisted during installation and check for any contact with suspension or steering components. Have an assistant push down on the vehicle and turn the steering wheel lock-to-lock during the inspection. Finally, bleed the brake system. When replacing brake lines, use steel brake lines and avoid using copper tubing. Prefabricated brake lines with flared tube ends and fittings are available and can be bent to the proper shapes using a tubing bender. Ensure that the new line is well-supported in the brackets and has enough clearance from moving or hot components. After installation, check the master cylinder fluid level and add fluid if necessary. Bleed the brake system.