My Garage

My Account

Cart

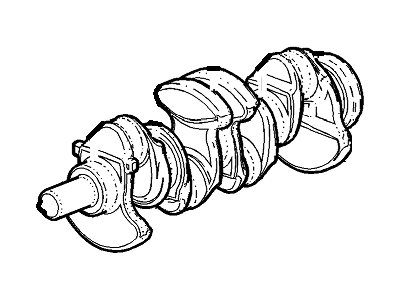

Genuine Cadillac CTS Crankshaft

Crank Shaft- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

15 Crankshafts found

Cadillac CTS Crankshaft

Part Number: 12661875$582.24 MSRP: $1004.39You Save: $422.15 (43%)Ships in 1-3 Business DaysCadillac CTS Engine Crankshaft

Part Number: 12623074$564.05 MSRP: $933.17You Save: $369.12 (40%)Ships in 1-3 Business DaysCadillac CTS Crankshaft Assembly

Part Number: 12641691$985.49 MSRP: $1279.87You Save: $294.38 (23%)Ships in 1-3 Business DaysCadillac CTS Crankshaft

Part Number: 12661873$526.44 MSRP: $900.16You Save: $373.72 (42%)Ships in 1-2 Business DaysCadillac CTS Engine Crankshaft

Part Number: 12603616$962.97 MSRP: $1593.80You Save: $630.83 (40%)Ships in 1-3 Business DaysCadillac CTS Crankshaft Assembly

Part Number: 12642339$652.04 MSRP: $1039.91You Save: $387.87 (38%)Ships in 1-3 Business DaysCadillac CTS Engine Crankshaft

Part Number: 90444055$101.45 MSRP: $1327.40You Save: $1225.95 (93%)Ships in 1-2 Business DaysCadillac CTS Crankshaft Assembly, .

Part Number: 12712984$1059.19 MSRP: $1375.58You Save: $316.39 (23%)

Cadillac CTS Crankshaft

Each OEM Cadillac CTS Crankshaft we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac CTS Crankshaft Parts Questions & Experts Answers

- Q: How can the crankshaft be removed and installed on Cadillac CTS?A:The crankshaft can only be removed after the engine has been pulled out of the car on the condition that such parts as the flywheel crankshaft pulley, timing chain cover, oil pan, oil pump body, oil filter, and Piston/connecting rod assemblies have been stripped off. Before withdrawal make sure of the crankshaft end float by putting the dial gauge parallel to the crankshaft. Push the crankshaft to the right and then to the rear to bring the indicator to zero then push the crankshaft to the left then note down the reading which should be within the range of 0.003-0.010 inch (0.076-0.254mm). Sometimes get of clearance can be approximated if dial-indicator is not available by use of feeler gauges. Unbolt the main bearing bridge and then free up and remove the main bearing cap bolts to the point where you can do so without dropping the bearing inserts. It is recommended that you lift the crankshaft out and seeing as they are quite heavy you might have a friend help you. For installation, make sure that the engine block and the crankshaft are clean and likewise check for any signs of damages. Raise the engine block in an inverted fashion, provide no support for the crank and remove any residual support and clean up the bearing surfaces. New upper and lower main bearing inserts have to be fitted, beforehand making sure that the oil holes are in place and aligned; no lubricant shall be applied at this time. Using Plastigage to check the oil clearance and make certain that the Plastigage is installed correctly and the bolts are tighten correctly and compare the width of the crushed Plastigage as shown on the scale. If clearance is not as specified, check the fact that no debris was in evidence when the clearance was measured, and consider machining or replacing the bearing inserts in this case. If you found some Plastigage on the crankshaft, then remove it, and apply some grease or assembly lube to the bearing surfaces and lay the crankshaft back in its position. The main bearing caps should be fitted correctly and oil put on the bolts before tightening as provided for. Lastly, once more adjust the crankshaft end-float and double check it for any drag on it before fitting a new rear main oil seal.