My Garage

My Account

Cart

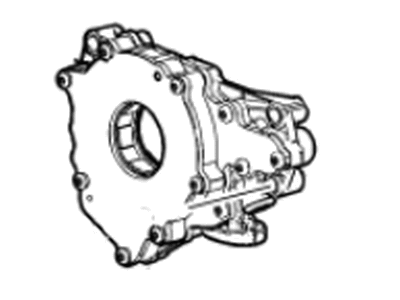

Genuine Cadillac CTS Oil Pump

Oil Fluid Pump- Select Vehicle by Model

- Select Vehicle by VIN

Select Vehicle by Model

orMake

Model

Year

Select Vehicle by VIN

For the most accurate results, select vehicle by your VIN (Vehicle Identification Number).

8 Oil Pumps found

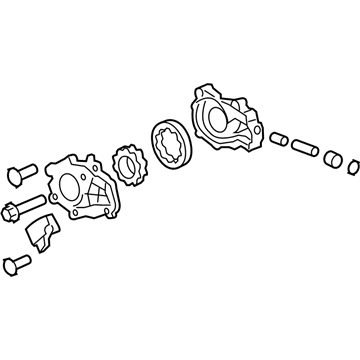

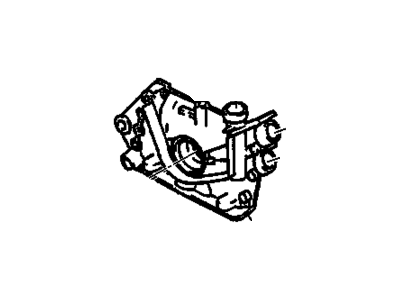

Cadillac CTS Oil Pump Assembly

Part Number: 12710303$72.66 MSRP: $175.99You Save: $103.33 (59%)Ships in 1-2 Business DaysCadillac CTS Pump,Oil

Part Number: 12640448$134.39 MSRP: $229.80You Save: $95.41 (42%)Ships in 1-2 Business DaysCadillac CTS Oil Pump Assembly

Part Number: 12686434$169.54 MSRP: $280.60You Save: $111.06 (40%)Ships in 1-2 Business DaysCadillac CTS Oil Pump Assembly

Part Number: 12674460$117.58 MSRP: $201.05You Save: $83.47 (42%)Ships in 1-2 Business DaysCadillac CTS Oil Pump Assembly

Part Number: 12696174$336.79 MSRP: $537.02You Save: $200.23 (38%)Ships in 1-3 Business DaysCadillac CTS Oil Pump Assembly

Part Number: 24266999$16.40 MSRP: $25.81You Save: $9.41 (37%)Ships in 1-3 Business Days

Cadillac CTS Oil Pump

The Oil Pump in Cadillac CTS vehicle is uniquely responsible for the circulation of oil under pressure which is vital in the running of internal combustion engine. It serves as an engine lubricant and coolant for bearings, pistons, hydraulic fluid for a number of small actuators, and coolants. Cadillac CTS usually incorporates mechanical oil pumps which are driven by the crankshaft or the camshaft which are quite reliable. Some of the pumps that may be used in the Cadillac CTS within the years may include gear, trochoid and vane pumps. The oiling system works perfectly to suck the oil from the sump, filter it and pump it around the engine ensuring it has the right pressure of oil which is very important. Cadillac CTS engine requires that it undergoes some regular maintenance such as oil change and filter to avoid incidences of system blockage.

Each OEM Cadillac CTS Oil Pump we offer is competitively priced and comes with the assurance of the manufacturer's warranty for the part. Furthermore, we guarantee the speedy delivery of your orders right to your doorstep. Our hassle-free return policy is also in place for your peace of mind.

Cadillac CTS Oil Pump Parts Questions & Experts Answers

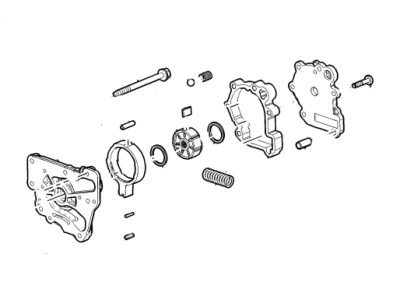

- Q: How to remove and reinstall the oil pump and its components in 2.8L,3.0L,3.6L V6 engine on Cadillac CTS?A:Before the plenum/intake manifold removal the valve covers, Timing Cover, and the Timing Chains must be noted to be identified afterwards, then the timing chain sprocket is to be removed from the crankshaft. Third, remove the oil pump retaining bolts and pull the pump off of the end of the crankshaft. For inspection you need to remove timing chain guide from the oil pump housing, then remove this housing and pull out the rotors from the pump body as well as removing the cover of the pump. Remove the snap ring of the side of the pump housing and pull out the cap, spring, plunger which constitutes oil pressure relief valve. With the solvent, clean all the parts and then dry them in a dry area; one should then check for signs of wear and tear, for instance, checking the bolt holes for signs of ruined threads and the splined surfaces on the crankshaft sprocket. Any of the components which are scored, scratched, or are worn shall require the replacement of the oil pump assembly since no separate components are available for replacement. If the oil pump is to be reused, attach the components of the pressure relief valve as well as the rotors onto the manifold of the oil pump and then flood the pump using clean engine oil between the rotors before putting on the cover and tightening the retaining bolts. The position the oil pump over the end of the crankshaft sprocket such away that the teeth on the crankshaft sprocket interlock with those on the oil pump drive gear making sure that the oil pump fits neatly against the block. On the oil pump mounting, bolt replace it with the new one and tighten the bolt as per the company recommended torque value. The rest of the installation proceeds in the opposite sequence to the removal. Other things are to put oil and coolant as required other fluids and start the engine and look for signs of any leakage and the oil pressure.